Foam swabs are among the tools that professionals use most in the cleaning industry, and ordinary people will strive to clean up themselves. Foam wrapped around a handle has a foam head attached to the handle, which can be used for cleaning even in the most challenging places and in various types of equipment, including advanced electronics and medical apparatus. This article summarizes the great foam swabs and their beyond-the-infection control applications. It will educate the readers on various types of available foam swabs, including their intended purpose, recommendations on their practical use, and proper care, enabling the maximization of such a versatile tool.

Foam swabs are constituted of three essential parts these being a foam tip, a handle, and an adhesive for sticking the tip into the handle. An array of applications for the foam tip within the Licensed Content include the use of open-cell foam for better liquid holding and absorbing capabilities. This type of foam is designed to reduce the generation of particles and lint, which is normally of great importance in a clean room or laboratory. Usually, the handle is made of strong materials such as polypropylene or wood planks, providing sufficient strength for the handle to be used efficiently and accurately. The glue used in constructing the ass míd’bling structure is designed such that it can endure solvents, chemicals, and other factors so that the foam tip does not come off during operation. The knowledge of the composition of foam swabs is pertinent when determining the relevant cleaning tools, as all the items used in making the swab enhance the effectiveness and make the swab appropriate for many uses.

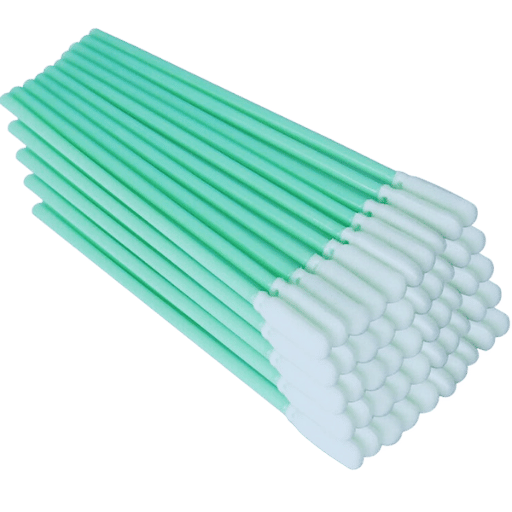

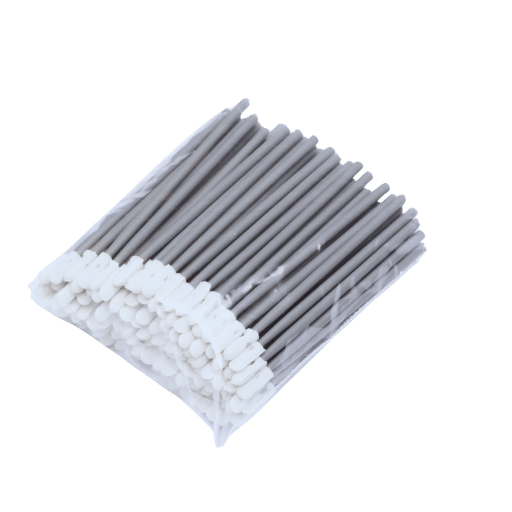

There are several types of foam-tipped swabs available for different purposes. The popular types are as follows:

Using the correct foam-tipped swab is important in maintaining compliance with regulations while maximizing cleaning effectiveness.

Clean swabs have wide-ranging acceptability in several industries like electronics, healthcare, and laboratories because they are versatile and functional, especially when they have a plastic handle for a better grip. The foam swabs enable them to clean the delicate parts of the electronic equipment without the danger of damaging any of the devices. While in healthcare, they play a pivotal role in the sterility of the environment or the health procedures being done. They can also be utilized to get to narrow and complex areas, which are much needed in industrial and laboratory settings where deep cleaning is required.

There are different ways in which the cleaning swabs can be of assistance to people. First and foremost, an enhancement in the level of cleaning and hygiene is achieved, which is very important in guarding against contamination and meeting required standards. Second, the raw materials used in foam swab production are mostly lint-free and non-abrasive; hence, residue and surface damage are avoided. For most other things, the shapes are so comfortable that it makes cleaning more effective and less tiring, even when carried out over an extended period. To conclude, cleaning swabs are indispensable equipment for cleaner efficiency and effectiveness in many aspects and places.

When choosing the proper foam-tipped swab, you should note a few elements, such as the length of the swab in inches and its handle type.

For effectiveness and efficiency in cleaning processes, the choice of the swab head and tip, tonality, and shape are critical. To begin with the foam density, thicker swab tips suit best for sucking and wetting more dirt, while thinner tips are recommended for delicate tasks. Further, the swab head should be of such shape as to fit on the appropriate cleaning areas, flat heads for still broad areas, but pointed heads squeeze and reach deep corners. In addition, check that the glue, which joins the foam tip to the stick, is strong and does not dissolve in solvents if employed cleansing liquid agents. Finally, the correct choice of swab head and tip is very useful in expediting the cleaning exercise without damaging the surfaces that are being cleaned.

The construction of the swab handle is certainly the most critical, as it directly impacts the user’s comfort when using it. Proper handle design maximizes ergonomics as users are offered a comfortable hand position that only exerts minimum effort, even when more effort is needed for long cleaning/sanitizing sessions. In addition, the handle aspect has to be made with an active material that is non-wearing to different washing materials so that it can resist passive wear through many operating conditions. This is because a rough, non-slippery surface helps to ensure the user bolts well while doing activities that require precision. Further, the length of the handle may also determine the extent to which one can reach or the ease with which a particular task can be performed with one hand. Therefore, a non-slip, ergonomically designed swab handle is reliable during use and improves the effectiveness of cleaning or application operations by providing adequate comfort to hold

Due to their unique properties, foam swabs have found a purpose in the electronics industry as they are capable of cleaning fragile and sensitive parts efficiently without causing any harm. The soft and spongy foam heads of the foam swabs are very effective in sweeping and cleaning off dust, particles, and contamination on circuit boards, connectors, and various intricate electronic components. Furthermore, the design of these foam swabs permits the cleaning of hard-to-get contacts, such as between chips or around places where solder joints are, along with other experiences when conventional cleaning implements may not be effective. The swabs can also be used with many cleaning solvents to remove excess residues like dirt and grease, and after soldering substances such as flux to improve both the functionality and lifespan of electronic items. It can be concluded that paper swabs improve cleanliness and function in electronic applications for imaging purposes.

Broadly speaking, foam swabs are its indispensable constituencies in automotive & car care applications primarily for their cleaning capabilities & the ability to execute details. Such soft foam heads prove especially efficient in cleaning out built-up debris present in tight areas of the engine compartment, particularly around sensors and air filters and sometimes electrical connections, which, if not cleaned, may result in a machine breakdown. The foam swab is also useful in detailing work, such as the safe cleaning of interior components such as vents, buttons, and dashboards and the elimination of dirt without risk of scratching fragile finishes. Moreover, they can also be used with different kinds of auto detailing products to apply grease, dressings, or waxes in an efficient manner and make sure of a ‘professional look clean’, reducing the possibility of residue. All of this shows that foam swabs are equally important for both professionals working in car detailing and auto lovers themselves, proving their role in good vehicle appearance and performance.

Medical foam swabs are highly in demand since they can be used at the same time for sterile cleaning and ultimate sampling. In the treated swab facilities, clinicians efficiently perform specimen collection or topical therapy application with the swabs, minimizing the possible risk of cross-contamination. Their composition allows imparted fluids to be absorbed fully, and hence, they are ideal for practices that entail the cleanup of wounds and drug application. In craft uses, batts are multifunctional implements for the dispersion of paints, adhesives, and topcoats. Its supple tips make it easy to use in case of spraying coatings evenly without wasting too much coating, minimizing fashioning quality. Foam swabs offer relevance and flexibility, whether applied clinically or in a creative setting.

Routine scrubbing and practice is vital if foam swabs are to be maintained and used for a comparatively long time. After utilizing each swab, it is recommended that the swabs be disinfected in accordance with the instructions given by the maker. It is also very important that such material is kept in a closed, sterile environment, preferably away in dry rooms without exposure to sunlight, which could cause harm to the materials with time. Regular checks should also be carried out on such swabs to check whether such swabs are broken or they are worn out; such swabs should be disposed of and new ones fitted. When these practices are observed, it will be possible to maintain the quality of foam swabs and, therefore, help whenever precise cleaning is called for.

If you are interested in buying foam swabs in bulk, some good online shops already offer this option.

These platforms provide convenience in purchasing, competitive pricing, and diverse options to meet specific cleaning needs.

Swab kits and packs may come in different configurations depending on the intended use, whether personal or industrial.

These options give users impeccable comfort and the freedom to choose the foam swab configuration best suited to their cleaning needs.

Approaching foam swab suppliers with a clear and brief request when looking for specific swabs is essential. First, identify your company and give some background on what you require, that is, the type of foam swabs, whether mini kits, standard packs, bulk packs, or any type of specialty kits. Often include minimum order levels, types of materials, and additional tolerances for particular industries. Furthermore, ask about lead times, shipping methods, and costs to know your purchasing capabilities for bulk items. Lastly, keeping the channels of communication open would help develop a good rapport with the suppliers, which will enhance service provision in the future, including such replacement items.

A: A foam swab can be a generic tool that may be employed in cleaning various activities like detailing electronic parts, cleaning unreachable places, and exchanging solvents. Hence, it is very useful in various fields. It is very important in the electronic industry, painting harbors, and firearm maintenance.

A: Called also cotton buds, foam swabs come from reticulated polyurethane foam or open cell polyurethane, Which is superior in absorbon properties and in trapping particles even more than common swabs than cotton ones. Additionally, it is endowed with a rigid or flexible handle made of polypropylene, which is more appropriate for industrial and electronic cleaning.

A: Yes, foam swabs are available in different sizes so that there is a swab for every cleaning need. For example, there are large detailing swabs that are thin and detailed, while the large rectangular foam swabs can reach places quickly as they cover more areas. You can easily buy them from sites such as Amazon or eBay, which have a variety of things that one can purchase.

A: Yes. Foam swabs are the most effective tools for cleaning electronics, given their low particle fallout value and high absorbent qualities. They prevent dirt and other substances from contaminating sensitive components as much as possible.

A: Yes, the foam swabs will be resistant to solvents. These are quite good when combined with IPA, coating, and other solvents, making this swab good for industrial use and general cleaning purposes.

A: Regarding packaging, foam swabs are often packed in bulk or in numbers such as 500. They come in different shapes, including large rectangular, rectangular foam, detailing swabs, mini, and many others, to suit various industry specifications. Please refer to the company website for more information.

A: The tips of applicators, the majority of their central part, and the back can be manufactured from reticulated polyurethane foam or open-cell PU foam, often with a polypropylene handle. Absorbent materials are reasonable, as are non-porous, flexible, and rigid tones as required.

A: Between the excessive particle containment and the minimal particle falloff, foam swabs play a crucial role in environments susceptible to contamination. In particular, they help preserve the cleanliness of components in the electronic and medical industries.

A: You can acquire foam swabs through specialty stores, industrial suppliers, or websites such as www.Amazon.com. If you look forward to booking the detailed product description or for any special needs, do not hesitate to contact us.

A: Yes, we do issue TDSs, which include detailed technical information about the individual products to ensure that all the products meet our high manufacturing standards. If you require any assistance or further details regarding TDS, please get in touch with us.