Fiber spools are essential for the telecommunications sector and the data transmission industry since these are the primary means to convey information through optic fibers. The objective of this guide is to comprehensively describe fiber spools, their different uses, chemical composition, and the properties that make them essential in complimenting the current trends in communication technologies. Besides this, the readers will also understand the techniques used in producing these items, the current technologies, and the standard measures set for handling and storing fiber spools for maximum performance. The article will provide general information on how engineers, technicians, and other professionals in the industry are provided with the necessary information on the use of fiber spools and their advancement in the world of connectivity issues.

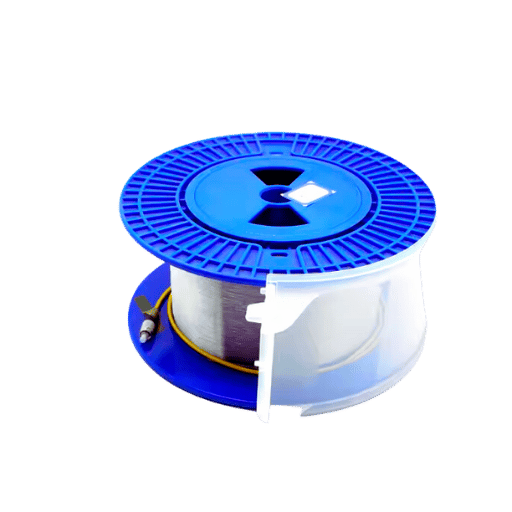

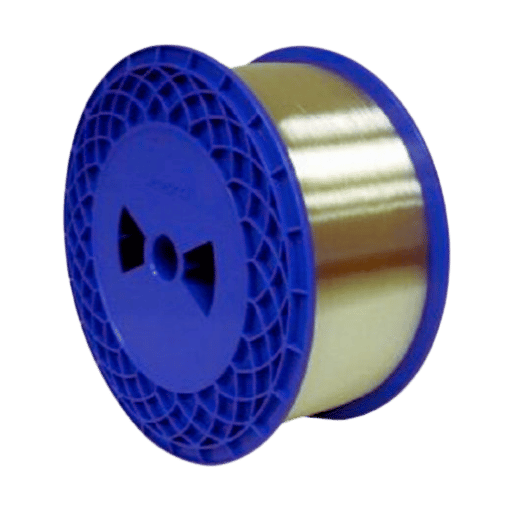

Fiber spools differ in the characteristics that define their performance and functionality in the telecom sector. To begin with, they serve to shield optical fibers from abuse and the surrounding environment so that they can be used for a long time with excellent reliability. The spools are usually made of high-quality plastics or metals, which provide good strength and durability. Some requirements that determine the application range of a spool include the fiber count, core diameter, and attenuation measure. Fiber spools, however, are designed for multi-distribution arrangements for simple installation and combination with other systems. Proper labeling and color-coding are also vital features for an excellent spooling system, making the connection of fibers quicker for maintenance and quickly zooming in on fiber pathways.

Optical fibers are the most significant components of fiber spools. They are very slender filaments made of glass or plastic that can send light signals for substantial distances with minimum losses. Such fibers utilize the laws of total internal reflections to transmit light efficiently within the fiber core. The manufacturing of fiber spools is such that optical fibers are not damaged. At the same time, the desired designs and strengths that are important for telecommunications are met. In that context, fiber spools act as the structure within which the fibers are systematically arranged for easy handling during use and cleaning, thereby avoiding tangling or breakage. In conclusion, the critical characteristics of a fiber spool – strength, detail of technical factors, and ease of marking – contribute to creating reliable and effective communication systems.

Bare fiber is one of the most critical elements in fiber spools because it is the essential element that carries the signals in optical communication networks. It comprises the uncompensated pure filament seated within the sheath of a fiber cable. Though it has no further cladding and coating, bare fiber is essential in testing, repairing, and demonstrating fiber optic systems. It enables engineers and technicians to access the quality and integrity of the optical bare fiber in terms of parameters such as signal loss and reflection. In the instance of fiber spools, the role of bare fiber in the spools is to allow for the bare-bones functionality of signal transmission using the simple fiber over long distances without any degradation of the signals.

To determine the availability of a fiber suitable for a high-performing network, it is essential to look at the differences between the two types of fibers: single-mode and multimode. The diameter of a core in a multimode fiber varies between approximately 50 micrometers and 62.5 micrometers, enabling a bundle of light modes to transverse through it concurrently. The diameter of the core ranges from 8 micrometers to 10 micrometers. As such, they allow only a single light mode to propagate through them. Allowing multiple light modes to propagate through a core makes multimode fibers advantageous for short-distance transmutation, such as in interlinks between local area networks and within data centers. Uniquely, single-mode fibers are advanced in managing long-distance connections in metropolitan area networks since they experience less modal dispersion and can transmit much data on a broader bandwidth, hence being more advanced than single-mode fibers. The choice of whether to use a single-mode or multimode fiber will ultimately depend on the requirements of the network.

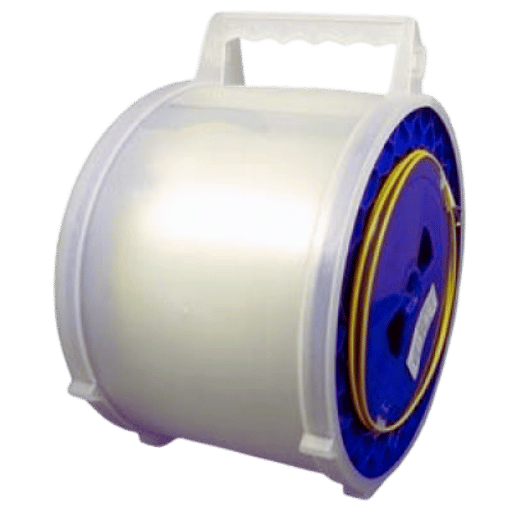

Fiber optic cable spools provide many benefits to network infrastructure owing to their organized structure and ability to safeguard the cable during installation and transit. To begin with, spooling makes it easier to deploy and install accurate wire lengths to avoid tangles or worsening the cable’s condition, thus reducing waste. Such optimal management of cables also enhances their physical conditions, improving the quality and strength of the signals and data being transmitted. In addition, fiber spools assist with the smooth sheath installation that allows for using spools in different circumstances, in this case, in a tight space in a data center or a large outdoor area. Lastly, spools can also improve cost-cutting measures in logistics by ensuring that transportation and storage are more bearable against mechanical and environmental conditions. All in all, using fiber optic cable spools ensures that the entire system is reliable, performant, and up to modern fiber optic communication standards.

Cable spools serve as a significant improvement to fiber management in storing and deploying fiber optic wire. Since the two ends are draped on the spools when they are reached for use, there is no chance of them getting physically damaged or tangled, ensuring the signal will remain strong. This arrangement is crucial in performance because it allows restriction-free analysis, repairs, and access to work without causing disturbance to existing links. In addition, cable spools assist in the loading process by offering a specified degree of tension, decreasing the strain exerted on the Close End Bungee Damping System, and decreasing possible breakage. Such orderly treatment preserves the effectiveness of the composite and the network structure, which, in the best way, increases the reliability and efficiency of fiber optic systems.

Bare fiber spools have a broad range of applications and are essential in fiber optic systems in various industries. For instance, bare fiber spools are needed in the telecommunications industry to support high data rates and long distances and provide reliable services in rural and urban areas. In addition, the medical sector employs bare fiber spools in complex devices like endoscopes, which need satisfactory performance and volumetric control of the fiber. Finally, the industrial sector utilizes fiber spools in the monitoring and control systems for automation and safety where reliable and effective transmission of information is required.

A few parameters must be analyzed to select the most appropriate fiber spool for your application. It is essential to determine the kind of fiber, single mode or multi-mode because these affect the distance and bandwidth in the transmission of the data. The core size and the diameter of the fiber cladding also significantly affect the integration with present systems and connectors. In addition, check the required tensile strength and the minimum bend radius to ensure that the spool can bear the stresses of installation and operation without any damage. Finally, it is helpful to examine the material from which the spool is made as it relates to the longevity of the fiber spools, especially given adverse weather. This, in turn, ensures that all the materials and components of the fiber optic systems are comprehensively and continuously maintained. That’s why you choose those products backed up by solid manufacturer support, including warranty and customer service, so your fiber optic systems are well cared for.

When developing and mounting fiber spools, it is necessary to keep mechanical and environmental factors in mind to guarantee good performance and longevity. First, check if the spool design encompasses the corresponding bend and radii of the fiber so that micro-bending losses do not occur, which otherwise would affect the signal quality. Ensure the temperature range is relatively low and the mechanical load is applied to the fiber to uphold its performance. Moreover, the cause of optical signal loss that stems from mechanical force applied on the fiber during installation can be avoided through proper orientation and strong fastening of the fiber. The capability of turn-up speed, maintenance ease, and connection with the existing wireless system also improve the reliability of the entire system. All these factors concerning design and installation should be considered for better performance and longevity of optic fiber networks.

Plenum and riser-rated fiber cables have been developed to meet specific fire safety standards related to the construction manipulation of structures. Cables rated as plenum are permissible for use in areas that assist in airflow for heating and air conditioning systems, usually found between raised floors and dropped ceilings. These cables are applied with fire retardant coating that does not produce a lot of smoke or toxic chemical emissions, thus meeting stringent safety standards such as that of NFPA 262. On the other hand, riser-rated cables are used in vertical shafts or between floors. These cables provide some level of fire protection but are not on the same level as plenum-rated cables and are more intended to prevent fire flow. The choice between these cable types is dictated by their intended use and local building code compliance, ensuring that safety and performance are achieved in different situations.

The fiber protection aspect during transport and storage should be considered when searching for bulk packaging voids for a bare fiver. Some other forms of packing include packages of spools, coils, and reels, all of which retain the functionality of the fiber. Long-span fibers usually have spools and reels as their forms of packaging; such advancement guarantees that the fibers do not get tangled and minimizes the creation of micro-bends that compromise fiber signal quality. While coils are generally for short fiber lengths and suitable for use with less complicated installations where deployment is more straightforward. Unique materials, such as anti-static bags and cushioning layers, must be applied to mitigate exposure to environmental conditions and mechanical shocks. Applying proper labeling and the correct documentation during packing time enhances the inventory and tracking requirements, improving the overall logistics processes.

Bulk bare fiber spools provide advantages that facilitate almost all telecommunications and data network applications. First, they are cost-effective as economies of scale are realized by purchasing fiber in more considerable bulk. Buying this option lowers the cost per unit for pre-terminated fiber assemblies. Second, spools allow for custom length in the field, meaning that fibers can be cut to the needed length for a particular job. This feature avoids cutting waste, and at the same time, the resources are optimally utilized. Third, spools enable easy stocking and moving of goods as the protection is built into the design of the optical bare fiber, which protects it from mechanical stress and environmental degradation when not in use. In addition to that, storing high amounts of fibers in a small size helps in the better and more efficient management of inventories.

Multiple websites are a great supplement if you want to fully comprehend how to use fiber spools. The first one is the Corning website, which specializes in optical fibers and contains in-depth information concerning different kinds of products, application instructions, and technical white papers. Secondly, the CommScope website focuses on fiber optic solutions, technologies, and trends that can help with installation. Finally, the Fiber Optic Association (FOA) has an exciting center of resources that teaches certification, advanced technical resources, and a diverse community of fiber laser specialists. All these resources are a great starting point for anyone willing to broaden their understanding of spool fibers and their use in the telecommunications industry.

From my research on fiber spools, I have identified suppliers such as Corning Optical Communications, FS (Fiberstore), and Anixter as distinct vendors, including them among potential suppliers. For instance, Corning Optical Communications has a website from which customers can directly place orders for their excellent fiber spools, thus guaranteeing the best available optical technology and its timely delivery. FS is active in the market because of its affordable sales, large amounts of goods, and stock availability. They ensure ease in selecting the required goods by buying and placing them online with pictures attached with the specifications. Anixter is recognized for its global reach, and thus, it sells a wide range of products, such as fiber spools and even fiber spools, as well as professional support services to fulfill all purchasing and logistical requirements satisfactorily.

If you are looking for high-quality fiber optic solutions, contact us using any of the contact details on our website. I’m sure many of you have many places to get information from, apart from my account, as you mention that their resources have insights from various leaders in the field. Using the educational material of the Fiber Optic Association, the technologies of Corning Optical Communications, and the pricing strategies of FS, we make sure that you get all the support essential for your telecommunications and data networking. Our team keeps up with the latest changes by checking these authoritative pages occasionally, which helps us provide timely and accurate options for your situation.

A: The fiber spool is also essential to optical fiber networks. It supports and organizes optical fiber cables while preventing them from being damaged and easing the installation process, especially in cases where there are many pairs of fibers. It is also essential to observe the correct bend radius, which is crucial in enabling optimum data transmission in high-speed networks and data centers.

A: Fiber spools are provided for various uses, so different types of fiber cables can be used. Some of the most common ones are spools for single-mode and multimode fibers, armored fiber cables, and bend-insensitive fiber cables. The spools can also be made for different types of wires, such as patch cables, breakout fiber cables, and MTP/MPO cables.

A: To select this fiber spool appropriately, consider your fiber, such as a single mode, OM3, or bend-insensitive. Also, consider the diameter of the cable, the length needed, and the conditions in which it will be used, such as plenum and riser. Also, consider what it will be used explicitly for, such as in data centers or high-performance networks. If you feel that more advice is necessary, consult with a fiber optic engineer.

A: Bend radius is an essential concern in fiber optics as it determines the signal’s integrity. Fiber spools are built to maintain the correct bend radius, which keeps the fiber safe and free from breakage caused by excessive bending. Using bend-insensitive fiber cables and spools with adequate radius specifications prevents the optical fiber from being bent too much and ensures that data is transmitted at high speeds.

A: Fiber spools make deployment and storage of fiber cables easy, making cable installation easy and requiring the least effort. They enable length precision, minimize tangling, and keep the fiber safe during installation, which is crucial. Some of the spools are also mountable so that they can be mounted directly into racks or enclosures, which makes it easier to install cables.

A: Plenum bulk fiber spools are manufactured for use in large open spaces; thus, they have different thermal insulation that protects them from fire. On the other hand, riser bulk fiber spools are designed for installations in towers needing wires to connect different floors and have lower fire resistance standards. From the bending radii perspective, the cable selection could be either a plenum or a riser, depending on the requirements of the building codes and Bellmouth installation location.

A: Fiber spools can be manufactured with different connector types adapted to them, such as standard LC or SC connectors and additional high-density MTP/MPO connectors. Preferred also are the spools made for pre-terminated cables using MTP Elite connectors or fiber pigtails, which allow more versatility to the varied network designs, including those dependent upon high performance.

A: Where there are many fiber connections in data centers, fiber spools are significant and assist in managing them. They help organize the cables’ incoming and outgoing traffic, ensure the wires maintain the minimum required bend radius, and ensure the cassettes can be easily pulled for maintenance and upgrades. Spools employed in high-performance applications, especially those with MTP/MPO-type high-density interconnects, are becoming critical for new-generation data centers requiring increasing high-performance data links.