Fiber patch panels are essential for present-day data centers and telecommunication networks, which organize fiber optic cables for easy use. Here, you can expect to find a complete guide on these panels that includes their different types, what they do, and why we need them, among other things. Moreover, there will also be tips for installing and maintaining these units so that they work best and last long in any network system. If you are an IT expert who wants better performance from your current setup or is just starting with computers, this should give everything necessary about fiber patch panels.

A fiber patch panel, or a fiber distribution panel, is used to conclude the fiber optic cables and offer entry to individual fibers for cross-connection. It cannot be overemphasized that these devices should have effective fiber management. This is usually done using a metal or plastic box that contains many adapter panels or cassettes for interconnecting and routing optical fibers. The fiber patch panel primarily makes it easy to manage different connections involving termination points and to identify and troubleshoot problems on optic circuits within networks.

Fiber patch panels are available in several types that suit different functional requirements and installation environments. The most common ones include;

Choosing the correct type of fiber patch panel enables network administrators to improve their optic infrastructure’s organization, efficiency, and scalability.

There are several things that could be done to make a network management system efficient with the use of fiber patch panels. Firstly, organization is enhanced as connections are brought together at one point, simplifying controlling them and finding out what is wrong or where the problem lies. Secondly, they quicken network maintenance procedures while upgrading since individual fibers can be accessed without interrupting the setup. Thirdly, its scalability feature enables network managers to add or change connections without much effort easily. Additionally, signal integrity is improved through these devices because they protect against too much bending and handling that leads to loss and degradation of signals. This makes for more reliable, manageable, and scalable fiber optic infrastructure systems overall.

Make sure you have the following tools and materials ready before you install a fiber patch panel:

Preparing well and having appropriate tools will make installation easier and improve the performance and durability of your fiber optic network.

These steps will help you install a fiber patch panel, improving your optic network’s reliability and manageability.

Wall mount fiber patch panels can be fixed to walls directly to facilitate compact and practical distribution and the management of optic fibers. They are usually employed in smaller networks or environments with limited space; thus, they come in diverse styles and types for different purposes. Also, it is possible to fit simplex and duplex adapters together in these wall mounts, which may have pre-configured or customizable setups. Among the features that can be provided with these units are lockable doors (for security), several cable entry points (for flexibility), and integrated cable management systems (to ensure proper organization as well as relieve cable stress). By adopting them, administrators will realize clean access points while saving time during fiber installation, improving overall network efficiency and reliability.

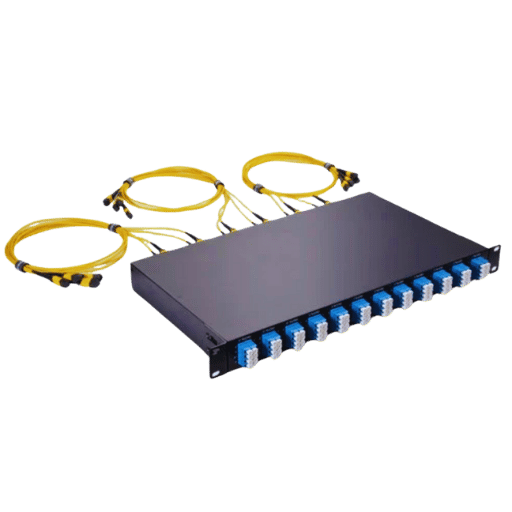

Ideal for larger network setups with a lot of fiber optic cable that needs to be managed, rack mount fiber patch panels are supposed to be put into 19-inch server racks. These units act as the central point where fibers can be terminated and spliced, thus making sure everything is organized and safe. Rack mount fiber patch panels come in different sizes, such as 1U, 2U, or 4U, all of which have the capacity for many fiber connections, further enhancing network scalability. Some have removable cover plates or slide-out trays allowing easy access during maintenance or reconfiguration. In contrast, others come equipped with robust cable management systems featuring bend radius protection, among other efficient routing mechanisms, to ensure maximum performance plus life span on any fiber optic network. They also support different adapters like LC, SC, MTP, etc., which gives them flexibility when connecting various components within a fiber optic system. Using these devices, data centers can be made more organized and cleaner, thus leading to faster speeds and better reliability across networks, according to network administrators who utilize them frequently.

Compact fiber patch panels are designed to ensure that space is used as much as possible by fitting more fiber connections into small spaces, which has become a very important aspect of modern data centers and telecommunication facilities. These patch panels allow for higher density by condensing many fibers into a smaller footprint, thus enabling interconnection without expanding physical space. Cable management aspects in high-density panels are usually advanced; for example, modular cassettes, which can be configured easily or upgraded conveniently, are among them. This makes it easier to maintain and ensures scalability during network growth periods while saving time due to simplicity during installation. Additionally, various other features are incorporated in these panels, such as ultra-low loss connectors and high-performance adapters, which greatly help reduce signal attenuation, thus contributing towards better network performance overall. Integrating this technology allows one to effectively deal with many fiber connections at once while improving data transfer rates and keeping the network design neat and efficient.

Fibre optic adapters and connectors are crucial for setting up and using a fiber patch panel. Fibre adapters, also called couplers, enable fast connections between two cables by accurately aligning the cores of their fibers to guarantee minimal signal loss and excellent network performance. LC, SC, ST, and MTP/MPO are standard fiber optic adapters, each made for different connector styles.

On the other hand, fiber connectors are used to terminate optical ends that should be connected with different devices used in networking. LC, SC, FC, ST, and MTP/MPO are the most popular types of these connectors, which vary in size compatibility and performance characteristics. Typically, these connectors are employed with fiber adapters to deliver secure connections within patch panels; thus, they should not be overlooked. High-quality connectors are necessary to reduce insertion and return loss so that signal integrity throughout the system is maintained at its best. Hence, fiber adaptors or couplings and their corresponding connecting parts play significant roles in practical operation and scalability within fiber-optic networks.

For a fiber patch panel system to work, cables and patch cords must link the different components. Different fiber optic cables are available, such as single-mode and multi-mode cables, each engineered for specific network environments and performance demands. Single-mode fibers are used in long-distance communication because they can transmit low-loss signals over longer distances. In contrast, multi-mode fibers are designed for short-reach applications with higher data rates.

Patch cords, also called patch/jumper cables, help establish direct connections between devices or from patch panels to equipment in data centers and telecommunications rooms. These short cords usually have pre-terminated connectors on both ends, ensuring a quick and reliable connection. Such setups often use LC to LC fiber connectors. The types of patch cords include LC-LC, SC-SC, and MPO-MPO, which match up with connectors/adapters used within the network.

When choosing cables and patch cords, it is essential to consider factors like compatibility with existing infrastructure, required bandwidth, and durability needed for reliable network performance improvement. High-quality cables and good patches reduce signal losses, enabling effective data transmission and enhancing overall network reliability and efficiency.

Splice trays and fiber enclosures are essential for fiber optic splicing organization and protection in a network. They manage splicing fiber cables to protect such connections from physical damage and harsh climatic conditions. These trays have divisions where splices are stored, and protective sleeves are used to safeguard fusion splices.

Conversely, patch panels or other components for controlling fibers may be housed within one place provided by a fiber enclosure. Depending on various network environments ‘ requirements, these enclosures come in different forms: wall-mounted, outdoor, and mounted types. They keep organized, accessible, and protected fiber optic connections, which significantly helps ensure network up-time performance remains stable throughout.

When choosing between splice trays and an enclosure, it is essential to consider the number of splices being made and whether they will be fusion or mechanical. The ease of access required for maintenance and environmental protection is also needed. Sound quality management systems significantly contribute to the longevity and reliability of optical fiber networks, thereby promoting uninterrupted data transfer while maintaining network integrity at all times.

Regular maintenance is essential to keep fiber patch panels reliable and performant. Here’s what you need to know:

If network administrators follow these tips for regular maintenance, they will be able to reduce downtime while ensuring their fiber networks last long and work efficiently.

To fix fiber optic network problems, do the following:

By following these steps, systems administrators will quickly determine what’s wrong with their fiber optics setup and fix it quickly without significantly affecting operations.

When you should contact sales for a replacement is a matter of several factors. It is important to contact the sales team if diagnostic tools consistently show intense signal loss or physical damage, such as visible cracks, which cannot be fixed. Once network performance has stayed below par even after trying all troubleshooting techniques and confirming all equipment configurations, it might be necessary to consider getting another one. End-of-life (EOL) notices from manufacturers or no availability of compatible parts are also signs that call for replacements; during this time, consulting with salespeople will help ensure the robustness and efficiency of the network infrastructure to minimize any potential downtimes and operational disruptions.

To meet specific network requirements, several steps must be followed when customizing a fiber patch panel enclosure. Firstly, it is vital to know the dimensions and design of the enclosure needed, whether rack-mount or wall-mount configuration. Such designs usually involve LGX modules. Secondly, the required number and types of ports should be considered, along with cable management features that promote good arrangement and accessibility. Also, the choice of material should be based on environmental conditions and strength, which may require stainless steel or aluminum for rugged protection against damage from external factors. Moreover, customization might include the integration of connectors, adapters, or splice trays depending on the fiber type used within the network being served.

Working closely with manufacturers through joint efforts, detailed design drawings are prepared alongside prototypes so as not to leave any stone unturned in meeting all specifications involved during this process. This enables finer modifications at the pre-production stage; these bespoke enclosures will fit seamlessly into the operational needs of different networks.

To guarantee compatibility with the network setup, it is essential to differentiate between pre-loaded fiber patch panels and modular options. A pre-loaded fiber panel comes readily assembled with adapters, making it easy to install since it saves time. It is most suitable for typical deployments where the network’s needs are well-known.

On the one hand, a modular patch panel offers more flexibility because it allows the administrator to customize by adding or removing modules to suit their requirements at any given time. This feature is advantageous for expanding networks as it supports scalability and simplifies maintenance. Moreover, within the same box, different modules can be mixed, thus providing a wider choice; this makes them perfect for environments that keep changing or those that expect future growth.

In either case, compatibility with existing infrastructure should be considered alongside cable management systems and ease of accessibility if we want our network operations to remain smooth.

Specialized fiber patch panel configurations and designs meet unusual operational stipulations and environmental restraints. These tailored solutions can involve high-density panels that utilize space well, angled panels that direct cables better, or rough-service panels that withstand severe outdoor conditions. High-density panels have been designed to provide many ports within a small area, making the limited space available in data centers more efficient. By allowing cables to flow naturally to one side, angled panels reduce tension on connections and increase airflow, which is good for cable management.

Ruggedized panels made from tough materials offer increased protection against moisture, dust, and temperature variations in hostile weather settings. Such outdoor fiber patch panels have been created specifically for this purpose. Furthermore, some come with integrated monitoring and management systems to enable real-time data analytics and network performance tracking. By selecting configuration options for specific situations, an organization can meet its unique network infrastructure requirements while ensuring dependable serviceability.

A: It is a device that allows for connecting fiber optic cables by providing termination points where fibers can be connected and managed within a network. This is also used to connect different optical fibers with other networking equipment, thus giving an easy way of organizing and handling such connections.

A: The 1u fiber patch panel is smaller in size hence saving space on racks within data centers or closets. They are usually provided with preloaded patches for convenience during installation. It fits into a standard 1u 19-inch rack, so it works well in high-density environments where there’s a need for maximum utilization of space coupled with simplified cable management.

A: These consist of twelve bare fibers with connectors already terminated at one end while the other side remains unconnected. They are applied to link optical devices like patch panels or similar equipment, thereby reducing the complexities associated with terminations and ensuring the reliability of connections.

A: Yes, adapter plates are frequently employed with this device to enable integration between different types of connectors, such as LC, SC, or ST. They make reconfiguration easy and also ensure that the patch panel can accommodate various kinds of fiber optic connectors.

A: Singlemode fibers possess smaller cores meant for long distance transmissions which have higher bandwidths whereas multimode fibers feature larger cores designed for short distance applications having lower bandwidths. In most cases, telecoms and long-haul data communications employ single-mode fibers, while local area networks (LANs) commonly use multimode varieties.

A: LC, SC, and ST connectors are among the most common connector types used in fiber termination. Each type has its own specific use cases and benefits. For example, LC connectors are known for being small, which is good for high-density applications, while SC connectors’ popularity stems from their push-pull design.

A: High density refers to packing a lot of terminations into a small space within fiber optic patch panels. These days, it’s common practice to use high-density patch panels in data centers and telecom rooms, where every inch counts toward maximizing space efficiency.

A: Some things you should consider when choosing include what kind (singlemode or multimode), how many ports you require, what type (LC, SC, etc.), and whether additional features like internal fibre management or adapter plates are required. Also, ensure compatibility with your existing fiber network infrastructure.

A: A 48 fiber patch panel with LC connectors will manage/terminate up to 48 individual LC fiber optic connections. The LC Connector is a small form factor, making them perfect for situations with limited space available due to their size. Because of their size, they work great in areas that demand higher-density connections per square foot.

A: To mount a 1U Fiber Patch Panel in Rackmount Setup, Align Panel Mounting Brackets with Rack Mounting Holes on the 1U 19” Rack Unit. Ensure that it is appropriately aligned. Secure it using compatible screws level and secure this will give you a stable platform so that you can manage your fiber optic connections from one central point.