Regarding modern communication, fiber optic networks are the central means behind everything from fast internet services to sophisticated telecommunications. Guarantees of the reliability and efficiency of these networks start with protecting their critical parts, such as fiber optic splices. Fiber optic splice closures play a role here. These are essential casings that ensure minimal damage in delicate interconnections between fibers, ensuring network performance. In this guide, we will cover all you need to learn about fiber optic splice closures – their designs, functions, and the part they play in securing your network infrastructure. This comprehensive blog post aims to provide information to technicians, network engineers, or anyone wishing to glimpse what makes up the core aspects of fiber optics, such as how to establish and maintain a dependable future-proof network.

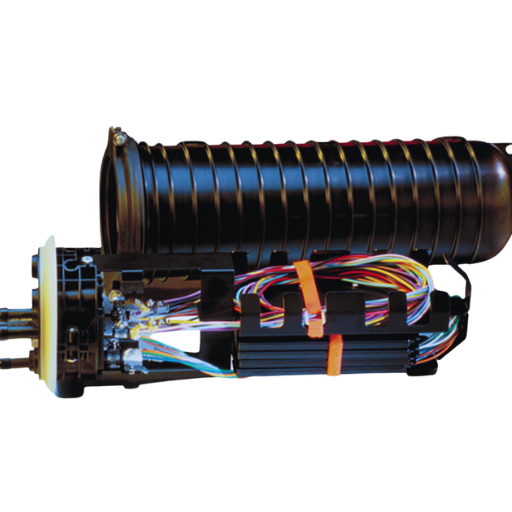

A fiber optic splice closure is a protective device intended to enclose and guard the spliced connections of fiber optic cables. It creates an air-tight environment that safeguards these splices from environmental considerations, including wetness, dust, and temperature changes; hence, the long-term performance of the links is assured. They are essential for keeping the fiber optic network’s functionality and reliability because they stop signal loss or damage, which can affect data transmission. They contribute significantly to the networks’ robustness and effectiveness by maintaining underground and aerial installations that secure splices.

One way of protecting and managing fiber optic splices in a network is by using splice closures. They help protect connections from environmental factors like water, dust, and extreme temperatures and thus guarantee consistent signal quality. Furthermore, they also allow for both underground and aerial deployments thus adding to the overall stability as well as performance of the optical fiber system. Essentially, these facilities are used to enhance uninterrupted data transmission over long periods that expand the operational life of any network.

Fiber optic splice closures have several components, which are essential in making sure they protect and offer a smooth operation of fiber optic connections. Here is an explanation of these elements:

Casing

Cases generally use high-strength materials like polypropylene or stainless steel to protect against environmental hazards, physical stress, and chemical exposure. The housing is usually waterproof and dustproof and conforms to IP 68 standards for long-lasting endurance, even in tough conditions.

The Seal

The presence of a strong sealant in the closure helps prevent water and air from entering it. In most cases, this is done by using rubber or silicone gaskets as well as heat-shrinkable sleeves that make a watertight seal capable of maintaining its integrity at temperatures ranging from -40°F to 158°F (-40°C to 70°C).

Splice Trays

Splice trays form the basis for managing and organizing fiber splices. They provide an organized area where fiber splicing points can be anchored and protected, facilitating easy maintenance. Most high-capacity splice closures can accommodate many splice trays, with each tray containing between 12-96 splice points, depending on the system’s design.

Cable Entry Ports

Fiber optic splice closures have multiple entry ports to support varying cable sizes and configurations. The said ports hold cables in place with the help of mechanical seals or compression fittings. High-density closures may have more than eight ports, ensuring that networks grow as required.

Strength Member Attachment System

A strength-member attachment system enhances the mechanical stability of a closure. This system strongly holds the central strength members of the optical cables, thus safeguarding the fibers from any disruption caused by tension, bending, and other external forces.

Grounding and Bonding Hardware

There are grounding and bonding elements integrated into many closures to provide electrical continuity while also offering surge protection in aerial installations. These systems ensure network security and minimal downtime during electrical events.

Fiber Slack Storage

Enclosures frequently contain fiber slack storage areas to prevent too much bending or damage. Proper fiber management, including a minimum bend radius (30 mm on average), is key for excellent signal transmission levels.

Environmental Adaptation Features

Advanced fiber optic splice closures have characteristics that enable them to deal with environmental changes, such as materials resistant to UV for aerial deployment or pressure-relief valves to adjust temperature-associated internal pressures.

These main parts function coordinatedly to boost the splice closures’ strength, scalability, and efficiency. Their strong construction guarantees reliable and fast data transmissions in older or emerging telecommunication networks.

Fiber optic connectors are made of any kind of telecommunication or networking purposes. These different types of closures for splicing fibers in communication systems can be discussed as follows:

Horizontal Splice Closures

Vertical Splice Closures

Fiber Distribution Closures

Marine Splice Closures

Aerial Splice Closures

Pressurized Splice Closures

Every kind of splice closure is designed according to specific requirements of network infrastructure targeting enabling optimal performance of fiber optic under various circumstances. Selection should take into account environmental requirements, installation type, and network architecture to ensure long-term dependability and efficiency.

There are some factors that you should consider when selecting a fiber optic splice closure:

Choosing the right splice closure guarantees the best network performance and reduces maintenance costs over time.

The shape of dome splice closures is cylindrical while being normally used for aerial, underground, and also pedestal applications. They provide better provision of high volume splicing that is needed in situations where space is less restricted. The strong construction of each closure guarantees that it keeps out moisture and dirt.

Inline splice closures, on the other hand, are small in size and rectangular, making them suitable for places where space is limited, such as underground vaults or conduits. It has been developed to accommodate linear cable configurations; thus, it can be easily accessed for maintenance or upgrading purposes.

When deciding between the two, consider the installation environment, required splicing capacity, and ease of access for future repairs. Both models emphasize longevity and dependability but suit different spatial and operational needs.

It is important to recognize that the initial cable count and possible future demands are two things that must be considered while assessing closure capacity and scalability. Choose closures that can support current splicing needs and provide modular expansion options for projected network growth. Moreover, stackable components or flexible tray systems in closures make it easier to upgrade without making substantial changes to the existing infrastructure. By doing this, you will be able to prioritize such closures, which ensure efficiency in the long term and adaptability in dynamic network environments.

Prepare the necessary tools and equipment

Be sure to have all the necessary tools and equipment available before you start. These include fiber optic cables, fusion splice trays, heat shrink sleeves, fiber cleavers, fusion splicers, buffer tube removers, and splice cases. Use high-quality materials to guarantee reliability and performance.

Inspect and Prepare Fiber Optic Cables

Begin by inspecting them to ensure that they are free from damage. Measure and cut the cables to desired lengths as required, allowing slack to be used for splicing. Be careful while stripping them of the outer sheath and buffer tubes to avoid damaging fibers. Take isopropyl alcohol, which can be used to clean over fibers, thus removing dust, greases, or other contaminants.

Organize Inside Closure.

Open up your closure for splicing work then determine where those cables will lay when it is closed again. Ensure buffer tubes are routed correctly by clamping them securely, which helps preserve cable integrity. It is important that cable management inside a closure is proper so that there is minimal bending, preventing any kind of damage to fibers.

Optical Fiber Splicing

To make the fiber ends ready for splicing, a high-precision fiber cleaver is used to produce clean and sharp cuts. This is followed by aligning and fusing fibers, which reduces signal loss. After this step, one should cover the joints with heat shrink sleeves and then heat them until they fit correctly using an optical sleeve heater.

Position Fibers in Trays for Splicing

Arrange the fusion fibers carefully in splice trays so that there are no chances of getting damaged. Ensure you secure the fibers correctly using recommended guides and grooves. Observe the minimum bend radius stated by a manufacturer as much as possible to avoid bending too much.

Seal Closure

Close the splice trays carefully. All buffer tubes and cables must be placed inside the closure’s main housing. In addition, ensure that closure seals well to prevent water entry or contamination into it. Assess the durability and watertightness of the seal by applying moderate pressure on it.

Testing and Inspecting

Perform Optical Time Domain Reflectometer (OTDR) testing before burying/mounting the closure to determine if splices are good. Check whether signal loss is within acceptable limits and recheck all components for proper assembly.

Closure Security and Deployment

Install the closure in its intended place, whether on a pole, underground, or wall-mounted. Use appropriate mounting brackets or hardware to secure the closure. For this reason, label the closure for future maintenance purposes.

Following these steps can ensure a reliable and long-lasting fiber optic installation. Signal loss will be minimal, increasing the system’s life span while reducing maintenance needs.

To install a dependable and safe fiber optic closure, the following tools and equipment are necessary:

Fiber Optic Splicing Tools

Closure Mounting Hardware

Testing and Inspection Devices

Protective and Auxiliary Equipment

Safety Gear

Investing in high-quality tools and equipment enhances the performance, accuracy, and longevity of fiber optic installations. Furthermore, following manufacturer specifications and industry standards ensures these tools are used correctly during the closure setup process.

Avoiding these common mistakes by installers can, therefore, highly improve the dependability and efficiency of fiber optic networks.

Maintaining fiber optic splice closures at an optimal performance requires me to do several things. First, I conduct regular visual inspections to see if any physical damages, pollutants, or moisture can affect them. As such, all seals should be in place since failing to do so will result in poor performance. Thus, it is essential to clean the closure’s external part and ensure that the internal parts, like connectors and splice trays, are free from dust or any debris. Also, the integrity of cable strain relief and grounding mechanisms needs verification not to impact tension-related damage. Through periodic testing using an OTDR (Optical Time Domain Reflectometer), I can perform preemptive actions toward potential signal loss or faults that may arise. These steps ensure that my system is durable and operates dependably.

Signal Loss or Attenuation

Water Intrusion

Physical Damage to Closure

Improper Inside Closure Cable Management Synonyms

Grounding and Bonding Failures Synonyms

Temperature-Induced Deformation Synonyms

Core Misalignment During Splicing Synonyms

By systematically identifying and addressing these issues, technicians can ensure the optimal performance of fiber optic networks and avoid extended periods of downtime.

To ensure the reliability of networks, fiber splice closures protect spliced fiber optic cables from environmental damage. Regardless, they may have to be replaced or upgraded due to changing network requirements, wear and tear or technology development. The following are essential considerations with data-backed insights for replacing or upgrading fiber splice closures:

Worn out or Physically Damaged

Fiber splice closures exposed to harsh conditions such as physical impacts, flooding, and extreme weather can deteriorate over time. Research has established that the probability of failure in a closure is significantly higher when it has been subjected to repeated temperatures above 140°F (60°C) or left underwater for longer periods. Regular examination helps detect corrosion signs, cracks, and compromised sealing before affecting network performance.

Network Expansion Or Increased Capacity

Transitions to higher capacity networks like 5G or gigabit broadband often necessitate splice closures with advanced design specifications. These modern enclosures provide superior characteristics, including enhanced sealing performance, increased port density, and better compatibility with different cable sizes. For instance, 5 G-designed enclosures typically support up to 2,000 fibers, providing room for high network growth with negligible downtime.

Aging Infrastructure

The best practice in the industry is to replace closures every 10-20 years, depending on use and the environment. Furthermore, a report from the Telecoms Industry tells us that old closures are more prone to leaky seals and internal wear, which increases the chances of fiber breakages as well as signal losses.

Safety Standards and Compliance

Legislation or new safety standards may make older closures obsolete. Therefore, changing to the most recent certified shut-offs, such as IP68 or GR-771-CORE, will offer maximum protection against water, dust, and mechanical strain. This reduces liability risks while satisfying the needs of present-day infrastructures.

Cost-Benefit Analysis of Repairs vs Replacement

Replacement becomes a better cost option than repairing when maintenance costs for an older unit exceed one-half of its purchase price. Moreover, this approach minimizes disruptions caused by frequent repairs that hamper network reliability, thus reducing downtime.

By using these criteria as a guide, network owners are better positioned to decide to replace or upgrade fiber splice closures to maintain their networks at high-performance levels for future technological changes. In conclusion, regular maintenance and modern infrastructure investments ultimately lead to improved customer satisfaction, lower operating expenses, and enhanced operational efficiency.

The development of heat-shrink and gel-based sealing systems is one of the major technological advancements in fiber optic splice closures. I know these technologies have gone a long way in improving protection against such environmental factors as moisture, dust, and extreme temperatures. In addition, mechanical sealing has been enhanced with advanced gaskets and clamps, resulting in better durability and reusability. These developments guarantee the longevity of the closures while reducing maintenance requirements and supporting reliability for a long-term network.

Advanced networks such as 5G and FTTH deployments require high-density closures. Such arrangements are manufactured to house these networks’ increasing number of fibers. In my experience, this might often include customizable setups and modular splice trays, which make for effective cable management and scalability. They can be said to have been designed so as to support multiple cable entry points and accommodate high fiber counts while still being sealed properly. It ensures consistent performance with minimal disturbance during future network expansion exercises to prepare them for the future.

Innovative closures have been developed with built-in monitoring to help networks operate more efficiently in real time. Advanced optical monitoring systems and sensors are present in these closures, which keep watch on parameters like temperature, pressure, and humidity inside the enclosure. The network management system is then updated with this information, empowering proactive maintenance and rapid identification of faults.

In fact, recent research shows that they minimize downtime significantly by about 40% through early detection of problems such as fiber signal degradation and physical damage to cables. Moreover, predictive maintenance measures also deploy these closures to ensure few field visits, reducing operational costs. These fit in perfectly with the current trend towards smarter “self-aware” infrastructure seen, for example, in FTTH or 5G applications. Monitoring systems integrated into closures enhance network performance, increase reliability, and guarantee scalability.

Fiber optic splice closures deployed outdoors face different challenges depending on the prevailing weather conditions, temperature fluctuations, and physical stress. This is achieved by designing the closures with sturdy materials that can protect their internal components even in very harsh environmental conditions. UV-resistant plastics or aluminum alloys are often utilized to prevent such closures from being affected by prolonged exposure to sunlight.

New versions of these enclosures, for instance, have thermal stabilization features that enable them to work efficiently over a wide range of temperatures spanning from -40°F to 158°F (-40°C to 70°C). Furthermore, these units are fitted with high IP (Ingress Protection) ratings like IP68, which signifies complete safeguarding against dust and water, including immersion in water for long durations. This is crucial since it prevents moisture accumulation within the system, resulting in signal loss in fiber-optic networks.

In areas with heavy snowfall, high winds or earthquakes, mechanical stress is also dangerous. To deal with this issue, the closures are subjected to thorough tests for impact strength, compression as well as endurance in vibrations. Take, for example, closures made to endure strong winds; they usually have streamlined profiles and reinforced mounts that help reduce drag forces while securing them during installation. Moreover, seals and gaskets are optimized to resist degradation from environmental elements like salt spray and industrial pollutants.

These modern fiber optic splice closures incorporate these advanced features and provide tough protection even under harsh outdoor conditions while contributing to overall network reliability over an extended period of time needed by today’s high-bandwidth applications.

Temperature changes can greatly impact the functioning of fiber optic splice closures when it is too hot, materials expand, which may put seals at risk, increasing the possibility of moisture getting in. On the other hand, low temperatures can make a material contract, which causes it to be brittle and eventually leads to possible breaking. To reduce such impacts, closures are built from temperature-resistant materials that remain stable over various operating temperature ranges. Closures must undergo thorough heat tests to ensure long-term performance by resisting repeated heating and cooling cycles without impairment, ensuring network reliability in changing environmental conditions.

For continuity of the network, fiber optic splice closures are specially intended to prevent possible moisture, dust, and other impurities. This is done by creating watertight and airtight surroundings, hence making use of strong sealing systems, including gaskets and O-rings. The efficacy of maintaining the contamination-free lining of these systems is checked following several measurements, for instance, water immersion as well as dust resistance, among others. Therefore, such closures protect delicate fiber connections against harm; hence, they contribute to the longevity and stability of networks.

A fiber optic splice closure, sometimes referred to as a fiber closure or FOSC, is an enclosure designed to protect and organize optical cable splices. In outdoor environments, it is essential to maintain the integrity of connectivity between optical fibers, thus providing reliable network infrastructure for various applications, including FTTH and FTTx deployments.

A: The main types of fiber optic closures are domed, inline, and terminal closures. These different kinds serve various purposes in aerial, underground, or buried installations. Some popular options are butt-style closures used at the end line and compact ones deployed in areas with limited space.

A: Fiber optic splice enclosures protect them by creating a closed container without access to environmental factors like moisture, dirt, and temperature. Many times, these come with watertight seals such as O-rings or gaskets, while gel or any other sealants can also be used to guarantee long-term reliability when they are installed outdoors.

A: The number of fibers a standard fiber optic splice closure can hold ranges considerably depending on its model and size. For example, compact closures may house 24 or 48 fibers, while larger enclosures can handle a few hundred to about a thousand. High-capacity closures might have multiple splice trays/modules for many splices, which are distributed along extensive networks.

A: Some important aspects of fiber optic closures comprise weatherproofing, ease of re-entry to facilitate repairs or maintenance, cable management, and adaptability to different types of cables, such as loose tubes, ribbons, and ADSS. The rest could be anything from a scalable modular design with integrated slack storage to one that accommodates fusion and mechanical splice types as well as SC or LC connector styles.

A: Installation methods differ depending on the surroundings. At poles or messenger wires, aerial installations usually utilize closures. When it comes to underground applications, the closure may be placed inside either a handhole or manhole. Buried applications just involve direct burial after appropriate sealing. However, other options for versatility exist like certain enclosures adaptable for any mounting kits or accessories used for diverse installation modes.

A: Although sturdy and long-lasting, periodic care is still necessary for fiber optic closures. It can be done through routine inspection of any visible defects, checking for broken seals and gaskets, and cable entry points’ integrity testing. For network enhancements or repairs, it is essential to ensure that proper re-entering procedures are adhered to so that closure protection is not lost.

1. Experimental Testing of the Technique to Safeguard Splice Closures against Optical Fibre Movement during Temperature Variations across Seasons

2. What else can I use to measure MA current?

3. Study on Factors Affecting Attenuation in Fiber Optic Communication

4. Design and Manufacture of Fiber Optic Microlenses Using Arc Fusion Splicing System