The advent of fiber optic technology has greatly impacted telecommunications and data transmission systems in the past several decades, providing greater efficiency. This technology’s core is fiber jumpers, which are also details for patch cords, including LC duplex and SC fiber optic types used to connect network devices. This article focuses on fiber jumper cables, presenting all the needed materials covering their types, applications, and technical characteristics. These rudimentary aspects are essential for providing a practical look at the concept of operation for fiber optic connectivity and the vital part played by the fiber jumper cables in effectively integrating seamless communication networks. You will also acquire the essential, necessary, and relevant information on fiber optic connectivity whether you are a network engineer, IT administrator, or a generalist interested in any new telecommunications device.

Fiber jumper cables, called fiber patch cords, are also short optical fibers equipped with connectors at both ends. These cables link the end devices to a network or join the network components in a fiber optic configuration. There are various kinds of fiber jumper cables, including single mode and multimode, which are based on the required distance and bandwidth. They provide dependable and high data rates for transmitting information with less signal attenuation to achieve efficient operation in the communication systems, making them essential parts of up-to-date telecommunication systems performance.

Fiber optic jumpers or fiber patch cables are an essential part of fiber optic devices, which are utilized to make physical connections among various network devices. It is these cables that help transmit light signals that help in the transfer of information in the fiber optic system. Fiber jumpers have the performance requirements of low insertion and high return loss and cover short distances from intra-rack cabling to long-haul cross-facility cabling or any other application in between. Due to their dependability and excellent performance, they are required in places such as data centers and telecommunication as they provide constant high-speed connections that are fundamental to the transport and storage of data and its communication processes.

Single-Mode Fiber Jumpers: These working or patch cables are used in long-distance communications, usually several kilometers or more. The single-mode fiber cable has a smaller diameter of a few microns (9 microns here), which allows light to be transmitted in a straight line down the fiber and, therefore, lower attenuation, which means faster communication.

Multi-Mode Fiber Jumpers: Multi-mode fibers work well in limited distances, typically under 2 kilometers. Their core diameter is bigger (50 or 62.5 microns), which supports the transmission of more than one light cone or mode at the same time. This creates more modal dispersion but is cheaper for short-distance communication networks.

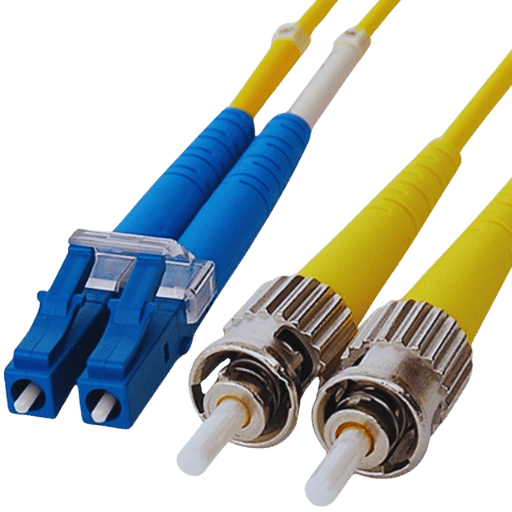

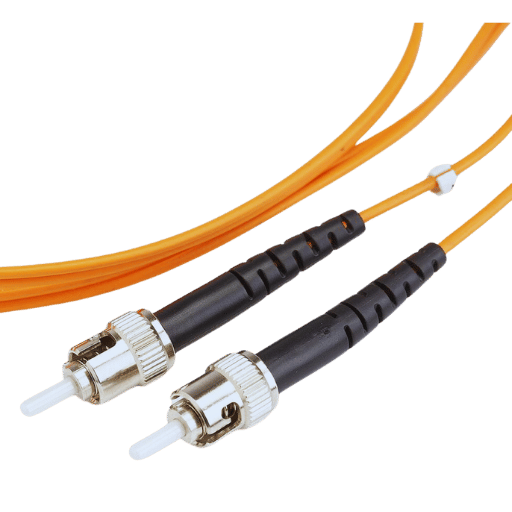

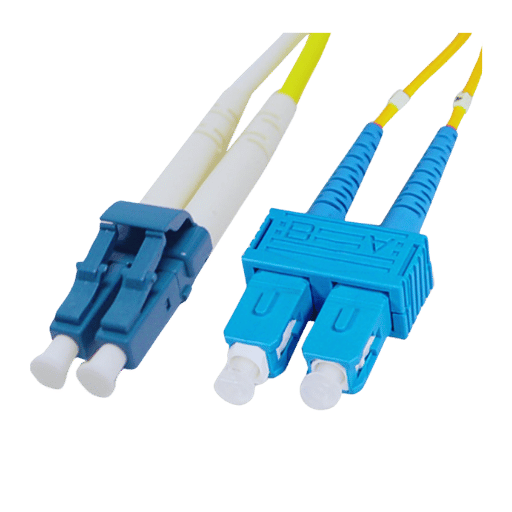

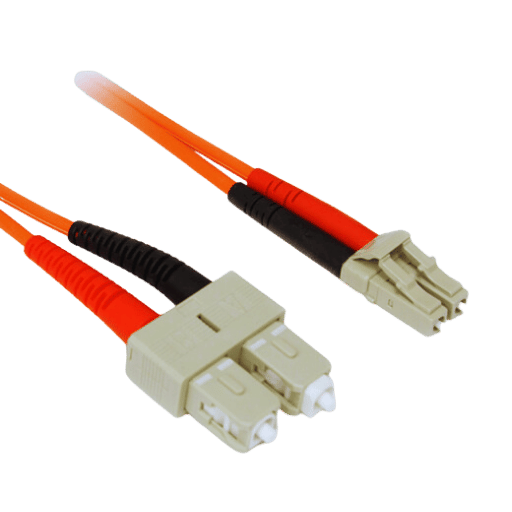

LC, SC, ST, and MTP/MPO Connectors: Fiber jumper cables can have various types of connectors, including LC (Lucent Connector), SC (Subscriber Connector), ST (Straight Tip), and MTP/MPO (Multi-Fiber Termination and Push-On/Pull-off). Each type has a particular use and field where it will require different precision, ease of fitting, and use of the already installed fiber optic systems.

Fiber jumper cables have three principal parts: the optical fiber, the connector (like LC duplex or sc fiber optic), and the protective outer solution. The optical fiber, made out of plastic or silica glass, is the center part through which light is transmitted. It is coated with a buffer that is more like a protector and helps preserve the output’s quality. Connectors, fitted on the ends of the fiber, play an essential role in reinforcing the connection between different network devices. Such connectors call for the polishing and adjustment of the ends of the exposed fibres with extreme precision if the loss of signals is to be minimized. The outer jacket helps prevent slacking, as it provides mechanical protection for the fiber against moisture and abrasion and any impact that can cause it to last and perform in different working environments.

Mode

The mode should be considered an important aspect of the fiber optic jumper configuration. It is advisable to use a single-mode fiber for long-distance transmission since it is designed with a smaller core diameter and has minimum losses. The inclusion of multimode fibers, on the other hand, compels using these types of transmission for shorter distances, i.e., within the building or campus, in consideration of the wider core radius and the capacity to utilize many light modes concurrently, which leads to higher modal dispersion.

Connector Type

A fundamental problem must be addressed: people making the wrong connector decision may render the existing network ineffective. LC, SC, ST, and MTP/MPO are common connector types used. LC has a small form factor and is precise; therefore, it can be integrated into high-density applications. SC connectors are preferred due to their satisfactory performance and user-friendly design, while legacy networks usually have ST connectors. Many customers also use MTP/MPO connectors in data centers because their size allows multiple connections in a single interface, which is ideal for high-density fiber environments.

Fiber optic jumper length is another important factor. The proper length limit provides the minimum slack and does not overstretch the fiber. Proper length measurement is critical in supporting effective performance since incorrect measurements lead to signal attenuation. Pre-measured lengths can minimize installation complexities and/or mistakes, thereby enhancing the reliability and efficiency of the optical network.

The selection of either single-mode fiber or multimode fiber is determined by the needs of the respective network and its application. Single-mode fibers consist of very small cores compared to multimode fibers. They typically have a core of about 9 microns surrounded by laser light to utilize bandwidths that may exceed ten kilometers. This, therefore, makes them suitable for transmission over telephone lines and data communication networks at relatively high speeds.

Multimode fibers contain larger core diameters of the order of 50 or 62.5 microns, and when an LED light source is used, they become effective in the short distance range. The maximum effective distance of 550m was excellent with 10 Gbps networking equipment connections. Because optical fibers support multiple light modes, this causes modal dispersion, which may affect the distance at which such a fiber can transmit. Hence, such fibers are commonly employed for interconnections, data centers, and LANs.

As a result, single-mode fiber is ideal for efficient data transmission over long distances, while multimode fibers would be more appropriate where distance and efficiency would be moderate in respect to funds expended.

The types of connectors involved are essential regarding the functioning and dependability of a fiber optic network. The LC is a type of connector developed by Lucent that takes up little space and is thus adequate in cases where density is crucial. The push-pull feature makes it easy to connect and disconnect and ensures that connections are secure and comfortable, thus reducing internal loss.

The SC is a push-pull type of connector, again, more of a variant of the Subscriber Connector—bigger and more sturdy. It is used in data communication and telecommunications because of its efficiency and dependable functionality, with low loss and high accuracy.

Another widely used type is the ST, a Straight-Tip connector commonly used in industrial applications with a bayonet locking mechanism. The other types are the MTP connectors or the MPO, which are used in dense fiber applications and interchangeably hold more than twelve fibers in a single casket.

The selection of every connection type is based on network design considerations, the availability of physical limitations on the system, and the trade-off of performance versus cost appropriate for the type of connector. If these connectors are well chosen and used, optical networks are efficient and reliable.

Performing the given actions brings the proper and fast installation of fiber jumper cables into the structure.

Compliance with industry standards is essential when it concerns the reliability and safety of network installations. For quality installation purposes, protocols such as the Telecommunications Industry Association (TIA) and the International Organization for Standardization (ISO) must be maintained. These standards outline various methods for proper statement, such as management of the cables, connectors being used, and performance testing.

In addition, such conformity facilitates the interconnectivity of devices made by various vendors and effective network utilization. Regular training and certification of installation personnel and the careful monitoring of documented procedures help ensure there is no deviation from the installation instructions.

Eventually, such regulatory compliance strengthens public confidence, reduces the prospects of installation errors, and guarantees the conformance of various network infrastructure components to the safety and operational standards required of them.

Jumper fibers are essential in data centers and other network setups as they provide different devices with high data transfer speeds and rapid interconnection between them. These jumpers create a link between a server, storage subsystem, and switches in a network, ensuring fast access to information and reduced delays. Fiber optic jumpers have low loss and very wide bandwidth, making them suitable for the relatively high data traffic needs in data centers. In addition, their performance is enhanced by the fact that they are not affected by electromagnetic waves, and there is effective transmission over long distances.

Fiber optic jumpers, especially ceramic ferrule jumpers, are also critical in the telecommunications industry because they support high-power broadband services and decrease losses in long-distance datalinks. These are commonly used in the Fiber to the Home (FTTH) architecture, where central offices are wired to residential or business subscribers. The application of fiber optic jumpers for these purposes means more bandwidth, faster internet, and better signals, which are necessary to satisfy customers enjoying high-capacity services like HD-content streaming and online games.

The installation of fiber optic jumpers is not only common in telecommunications but also in medical and industrial applications because the transmission of data is faithful and accurate. In the medical sector, such items find application in diagnostic imaging modules and other devices, such as the surgical endoscope, which require real-time data streaming in high definition. This aids in proper diagnosis and efficient treatment procedures. In industries, fiber optic jumpers are used in automation and control systems to provide safe and unbroken communications within and between automated production plants and processing facilities. Their design and resistance to extreme environmental conditions make them suit such applications.

Regular care of fiber jumper cables guarantees their functionality and durability. Among the most important procedures are:

Carrying out these maintenance practices on a regular basis helps maintain the performance and increase the lifespan of fiber jumper cables, thereby increasing the proper functioning of the network.

Testing the performance and integrity of fiber jumper cables is one of the aspects that should be performed to enhance the quality of the network operations. The following methods are usually applied:

Following a systematic approach in applying more resistance testing techniques helps to safeguard and improve the quality and efficiency of fiber jumper cables and hence stability of the network.

In order to properly test fiber jumpers, the following tools and machines are more than necessary:

When these tools and equipment are available, they assist in performing extensive tests without compromising the performance and reliability of the fiber optic network.

A: An example of a fiber optic cable transmits data using light signals through fragile strands of glass or plastic. Unlike conventional copper cables, fiber optic cables have much more bandwidth, and the light travels a much longer distance and is less sensitive to electromagnetism. They are widely used in telecommunication, networking, and other high-speed data flow systems.

A: The core structure of single-mode (OS2) and multimode (OM1, OM3, OM4) fiber patch cords are different, as is the light transmission mode. Single-mode fibers allow only one mode of light and hence have a small core diameter of about 9 microns, which allows longer distances. These cables have different core diameters, but large core diameters (50 or 62.5 microns) allow light multiple paths, hence shorter distances with less expense.

A: Fiber optic connectors encompass highly specialized parts that couple or connect fiber to equipment. They accomplish essential functions by interconnecting cable ends and providing minimum signal loss. Common types of fiber connectors include LC, SC, and ST. The application, equipment, and performance criteria define the adaptation of a connector.

A: There are two types of fiber optic connector polishing: UPC (Ultra Physical Contact) and APC (Angled Physical Contact). UPC connectors terminate in a flat end face, which is polished to 0-degree angles, while the end face of APC connectors is at an 8-degree angle. Generally, it can be said that APC connectors provide a better return loss performance, making their use in applications of advanced signal quality, such as long-distance or FTTH (fiber to the home) networks, more effective.

A: Fiber patch cords are also referred to as jumper patch cords or fiber jumper cables. They are short cable assemblies with connectors on two or both ends. They are used as interconnection cables for equipment like fiber optic systems, patch panels, and other types of networks. Fiber patch cords demonstrate several characteristics, including lengths, types of connectors, and types of fiber (single mode and multimode).

A: A duplex fiber optic cable uses two fibers, usually bundled together for two-way communication. Here, one fiber is used for data transmission, and the other is used for data reception. Nuclear medicine imaging systems and communication systems, relays, and fiber-optic telephone systems are typical areas where duplex optical fibers find applications, such as data centers where two-way communication is needed.

A: Bend-insensitive fiber patch cables are constructed for applications such as those requiring sharp turns in fiber optic cables while maintaining perfect signal quality. Such wires have managed to diminish the loss of signal caused by bending, improve performance in cases where space is at a premium, and enhance the despising of the layout of cables. These can be deployed in data centers, high-density network closets, and applications that are limited by space.

A: Riser-rated (OFNR) and plenum-rated (OFNP) fiber optic cables vary in their intended use and flammability rating. Since OFNR cables only run vertically from one floor to another, they have moderate fire performance capabilities. OFNP cables have even better fire resistance since they can be used in sealed environments wherever plenum spaces are present. Plenum-rated cables are more costly, but they are also much better rated in terms of fire protection.

A: When selecting a fiber patch cable, consider the following factors, which include and are not limited to fiber type, connector type, and jacket size (2.0mm or 3 mm) as well, cable length, jacket type (for environmental purposes), fire rating (OFNR or OFNP), polishing type (UPC or APC) and performance levels (OM3 or OM4 for 10G, 40G or 100G applications). Also, another factor that needs to be addressed is the type of devices and network you are connecting to.

A: Observing care and cleaning methods for fiber optic connectors for optimal operation is essential. Use the right cleaning instruments, such as lens wipes, fiber optic cassettes, or fiber optic cleaning pens. Use a fiber microscope and check the connectors for dirt or damage on a routine basis. It is essential to be careful to apply reasonable force while cleaning and never use bare hands to wipe the connector end-face. For more difficult contaminations, apply 91% isopropyl alcohol and use dry heating. Proper cleaning aids in the stability of signals and the protection of costly network devices from damage.