The FC connector is one of the most significant in fiber optic communications. The FC connector is one the oldest and perhaps the most widely used fiber optic connector which can be relied on even in hectic conditions. The purpose of this guide is to present the most used FC connectors, their configuration, purpose, and the spheres of use. Further, we will discuss the strengths and potential weaknesses of such connectors and the best practices for using and maintaining the connectors offered on this page. Readers will thus appreciate the details of the FC connectors and how essential they are in fiber networks.

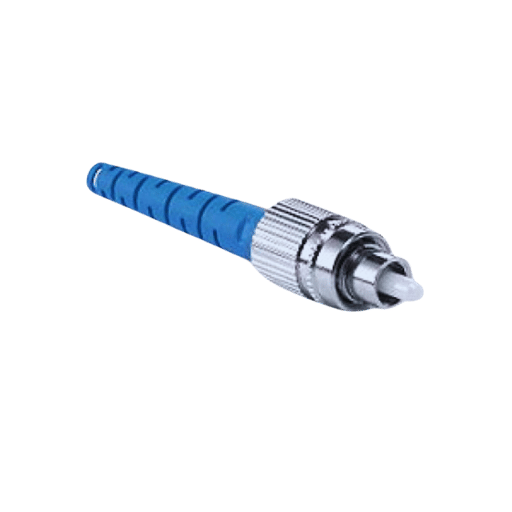

The FC connector or ferrule connector is synthesized for singlemode fiber optic optics and has become very popular because of its reliability. It has a screw-type lock that guarantees a firm and secure connection, an advantage in high-vibration situations. The Ferrule of the FC Connector is constructed in silicon, stainless steel, and plastic, and fibers are mounted to ensure proper connection. This construction goal is attributed to the reasons for the losses and reflection of the signal, making it a high use in telecommunication and data communication systems.

The presence of a screw characterizes FC connectors. This helps fasten the connectors tightly while minimizing environmental and mechanical damage to the connector. This screw-on design warrants minimal insertion loss and optimal return loss, which makes the FC Connectors favorable where precision is required in fiber optic systems, especially with zirconia ferrules. Usually, an FC connector consists of three main parts: the ferrule, the threaded metal barrel, and the coupling nut wire in place. The ferrule is often filed so that precise core alignment is accomplished using ceramic or metal materials since it is crucial in enhancing signal integrity.

Geometrically complex and possessing these features, FC fiber optic connectors are extremely important for the reliable and efficient operation of modern fiber optic communication systems.

FC connectors are widely used in many application areas owing to their solid construction and effective working ability. The main areas comprise:

These capabilities allow the FC connectors to be employed in numerous sophisticated and essential communication systems.

Each of the two types of intelligent connectors (FC and SC) is typically selected depending on the application. FC connectors are valued primarily for their threaded coupling, which can maintain an effective connection even in cases of high vibration or mechanical shock. Therefore, they are most suitable for areas like industrial automation and telecommunications, where the reliability of the connections is necessary.

In contrast, Qin’s Subscriber Connectors are easier to use and quicker to install, based on a reasonably effortful snap-in push-pull mechanism. They are prominent in the fore & back office or data centres which require quite limited amounts of space along with rapid marketplace employment of standard connectors. A slightly lower return loss is obtained with SC connectors than with FC connectors; however, in many high-density environments, their simple construction wins out over the more considerable return losses.

In conclusion, FC-type connectors are suited for applications where high-stability connections are required, whereas SC-type connectors represent the connecting device intended for an atmosphere where simple operations and quick connectivity are top priorities. Every connector has its merits, and it all comes down to the choice of application.

DS (Dual Fiber Socket) and CF (Ceramic Ferrule) connectors have several features that make them a favorite in varying circumstances. FC connectors employ a screw fastening method; thus, they are more mechanically stable and can withstand harsher environments. As a result, they are suitable for telecommunication, where it is necessary to keep the connections secure.

This type of connector, however, does not work with LC directional connectors, which can smoothly work among most structured cabling systems. For instance, in Data Centers, LC connectors have a small physical dimension or Small form factor (SFF), which means that more ports can be fitted into less space. They also offer low installation effort and low insertion loss or few interconnections and sorting, making operating correctly in compact spaces possible.

FC connectors are more appropriate in scenarios with numerous connection changes and permanent fuses, whereas LC connectors are most suitable in public houses that are parasitically integrated. Solutions are designed based on each type’s ability to function efficiently.

Both FC (Ferrule Connector) and ST (Straight Tip) connectors have their advantages and disadvantages, especially concerning their designs and purposes.

Advantages of FC Connectors:

Disadvantages of FC Connectors:

Advantages of ST Connectors:

Disadvantages of ST Connectors:

Ferrule connectors say FC, are favored for applications involving high stability and durability, bearing in mind that ST connectors are meant for quick and inexpensive use. This situation is such that a decision has to be made for either the FC connector or the ST connector, but only as per the demand and the surrounding factors of the application.

Single-mode FC connectors are specifically designed to fit single-mode fiber optic cables. This type of fiber optic cable is more suitable for long-distance data transmission and high-bandwidth applications. These connectors have a very small core diameter of about 9 microns that can only transmit a single mode or a single light wave simultaneously. This reduces the signal loss and spreading, and hence, better and clearer signals are obtained over a large distance. Integrated with a high-precision ceramic ferrule, the connectors ensure precise and low losses during insertion, making it a good choice for high-performance telecommunication and data center applications.

Multimode FC connectors are generally suitable for use with multimode types of fiber optic cabling, and this type of cabling is implemented in short-distance data transfer facilities usually situated in local area networks LAN or data centers. These connectors use larger core diameters, approximately 50 or 62.5 microns, which is capable of allowing the propagation of different modes or wavelengths through the fiber. Due to this larger core diameter and more light paths, it is evident that there will be more modal dispersion in these types of connectors, therefore making them less ideal for long-distance transmission use. They also have a ceramic ferrule, which provides high precision and low insertion loss since the fibers are perfectly aligned. In situations where data transfer is to occur over high speeds and short distances, multimode FC connectors are effective and provide a good solution.

Unlike standard FC connectors, Polarization-maintaining (PM) FC connectors are used in systems where it is necessary to maintain the polarisation of light within the fiber. Such connectors are most often employed in interferometry, fiber optic sensing, quantum cryptography, and other fields demanding a high degree of precision. Back-dazs- Yongkai- based-fc Lock-cage- Temporarily retain-for-site Core connectors have an asymmetric core structure and require accurate rotational positioning to preserve the plane of polarization of light and reduce the power leakage caused by unwarranted interaction between axes (cross-coupling). Angled connectors were developed with normal FC-type connectors, APc (angled physical contacts), which have taper-faced centers built into the ends of cylindrical housings so losses from reflections are minimized. Such specialized connectors broaden the scope of basic FC connectors to properly address the progressive needs of contemporary optical systems.

As with other fiber optic connectors, maintenance practices for FC connectors are very important for their efficiency and durability. Some of them include the following:

Following up on these maintenance aspects helps reduce the frequency of failure in transmitting quality signals and also increases the usage of FC fiber optic connectors.

Due to low insertion loss and high reliability, FC connectors are preferred in applications requiring critical and consistent signal transmission. FC connectors are threaded to enable a firm grip, eliminating the chances of signal quality loss due to positional offset. Similarly, the connectors’ solid construction tolerating mechanical stress embraces the elements of durability even in harsh environments. Finally, due to the systematic process of polishing FC connectors, the insertion loss is further minimized, increasing the effectiveness of the whole fiber optic network.

Extraordinarily constructed, the FC connectors endure the high vibration surroundings. Their screw coupling assures a tight and secure connection that withstands displacement under mechanical abuse and vibrations without degrading the connection integrity. These connectors have a rugged design and strong materials. It makes the FC connectors suitable for industrial, military, and other uses where the operating conditions are expected to be severe and dependable performance is necessary.

FC connectors are versatile and can be used with single mode and multimode fibers. Being fully standardized in such industries, it makes it possible to incorporate such connectors into existing networks, making it easier to upgrade and expand. Such compatibility covers even the telecommunication and data center applications, which efficiently and reliably bridge connectivity. FC connectors are also very flexible, making it easy for engineers and technicians to handle any kind of fiber optic project.

A: A connector FC is a type of optical fiber used in a fiber optic telecommunications or data network. It has a ceramic ferrule and a female thumbscrew connector at the rear. The connector operates as an optical alignment of the fiber optic cores, enabling the passage of light. FC connectors are high-precision connectors made so that fiber ends are brought in contact with each other and, therefore, are less prone to back reflection loss, improving the transmission level.

A: There are numerous advantages of using FC connectors, including: 1. Good performance in single-mode fiber applications 2. Locking feature due to the use of threaded connectors 3. Minimized insertion and back reflection losses 4. Reliability and survivability in highly vibratory conditions 5. Works with many such adapter types. 6. Ends of the fibers are kept in touch to reduce loss during transmission of light

A: Although FC connectors are well accepted and used in the industry, SC and LC connectors take the lead due to their miniature size and easy pushing and pulling fitting mechanism. Mendes and Ammad-Abderahman-Susnitskiy SC LC connectors are usually more user-friendly and allow more connecting density than their counterparts. Nevertheless, FC connectors do perform well in areas that experience high vibration. Still, these remain the order of preference for some military and industrial applications where it is easier to connect worsted connections.

A: Strain relief is essential in FC connectors as it removes stress that can otherwise damage the fragile optical fiber through pulling or bending actions. The strain relief boot, which is generally thin rubber material that protects the cable from the bend where the cable reaches the connector junction, engages with this feature. It has the additional advantage of preserving the integrity of the connector and reducing stress on the fiber, hence prolonging its use.

A: FC connectors are mostly simplex in that they only terminate a single fiber at a time. Although there are duplex FC connectors, such connectors are worn less than SC and LC types. For high duplex applications using a single connector such as the duplex are not suitable and as such, two simple FC connectors are fitted with a duplex adapter.

A: As for the FC connectors, UPC means Ultra Physical Contact, while APC means Angled Physical Contact. These terms denote the polishing methods of the ceramic ferrule used at the interface of FC connectors. The end face of the UPC connectors is flat, leading to an overall low back reflection. The end face of the APC connectors has an 8-degree angle, leading to even better back reflection, which is important when dealing with high-power or sensitive applications. This omission is filled by a specific geometry of the corresponding end face of the Optic Fiber Adapter that one uses – UPC or APC.

A: FC connector maintenance tasks are preventing the proper mating of the mating surfaces of the connectors 1. While not in use attaching dust caps to connectors It is Cleaner Ferrule Lower Face Aperture with Optical Maintenance Tools adjusted for Item 1: 2 Inspecting the surface of fiber optic connectors for dirt and physical damage 3 Never place, touch or press the surface of the ferrule adapter end face. 4 Applying adequate methods of thrust insertion and extraction of the connector to avoid mechanical stress damage 5 Keeping the connectors in proper or relocating the connecting instrument to an environment that is sufficiently clean, safe, and dry Regular cleaning and maintenance practices assist in optimal functioning and lifetime of the connectors FC.

A: Various standardizing organizations have documented and published some more specifications for FC connectors, among which the most important are: 1. IEC 61754-13: Fiber optic connector interfaces—Type FC connector 2. TIA-604-4: FOCIS 4 Fiber Optic Connector Intermateability Standard These normative documents consider mechanical and optical characteristics for FC connectors, allowing one to use FC connectors from various companies and in various applications.