The unprecedented technological growth we are experiencing today has made it necessary to have flexible and resilient solutions. This is where together master cables Extreme Cables come into play, October 2023. Extreme Cables can provide excellent performance and flexibility for various industry applications. Considering this, the article will explain the core functions and applications of Extreme Cable, emphasizing the company’s specific features that appeal to professionals who rely on efficacy. Having realized the critical advantages of the cable to its users, it should be obvious how this technology can suffice and surpass their connectivity needs.

Extreme Cables differentiates itself in the cable business by focusing on high-speed data transmission, cable strength, and adaptability to different environments. The firm employs technologically advanced materials and is vested in engineering so that each cable can cover the required performance benchmarks, guaranteeing connectivity even in severe circumstances. Thus, all their products can withstand the most demanding requirements. Their proactiveness towards research and development enables them to be innovative. That is why Extreme Cable’s solutions can be regarded as future-oriented in relation to new technology changes and requirements. Also, they stand out because they are committed to ecological protection while manufacturing the cables.

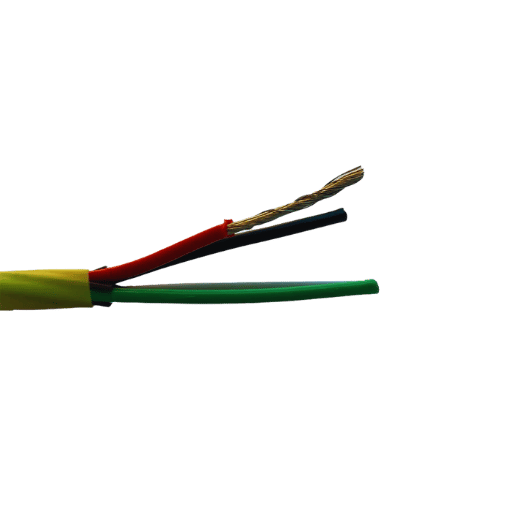

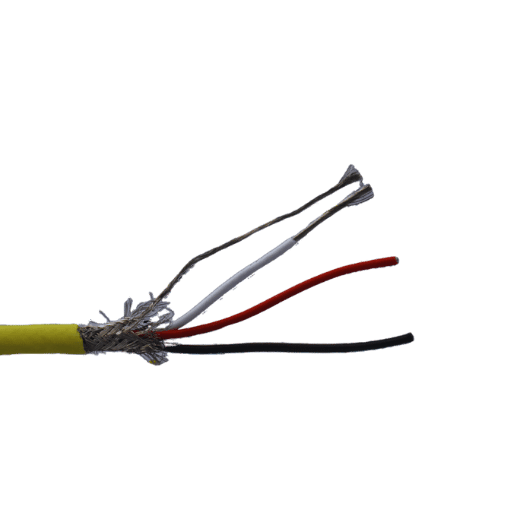

Extreme Cable is built considering performance even in harsh conditions such as high temperatures through advanced materials and custom designs. Within the cable is included the conductor, which has the superior grade needed to transmit data efficiently. The core is integrated with protective anti-thermal and electrical polymer layers, enabling the cable to perform well in high-heat environments. Strengthened coverings that block out EM fields and preserve signal quality follow this. The sheath at the outer level of an Extreme Cable is made of high-durability materials to offer the required corrosion and weather protection, therefore accommodating any form of application. This detailed layer construction assists Extreme Cable to provide extreme reliability and long life while conforming to the changes that modern industries require.

As a result of its significant contribution to conductivity and malleability, even at high temperatures, copper substantially extends the life of the Extreme Cable. Being the foremost wire ensures that data transmission relies on a consistent and efficient input, which is necessary for all systems that work under harsh conditions. With natural strength and corrosion resistance, copper extends the operating life of the cables and reduces their maintenance and replacement expenses. Furthermore, its ability to resist environmental stresses without any deterioration also adds to the durability of Extreme Cable, which gives it an edge in areas where quality and durability are the priority factors.

A flexible jacket is fundamental since it adequately protects the cable’s functionalities and physical characteristics during stress and environmental changes. Such a design allows the wire to deform by bending, twisting, or Shearing, reducing the chances of wear and tear owing to friction or shear forces due to constant movement or heavy-duty operations. The flexible jacket also adds further insulation against wear and mechanical shifts, ensuring quality output in extreme environments. All these aspects contribute to the increased lifespan of the cable, and in applications where reliability and durability are essential requirements, this is ideal.

Extreme Cable is designed to ensure structure and operating capabilities in extreme heat situations. It stems from my research of top resources that high-grade materials are chosen for their heat resistance properties, thus enabling the cable to operate in conditions that would destroy cables of lower quality. The copper conductor allows heat to be dissipated better with its stability, and the flexible jacket offers good thermal insulation. This design provides ease of operation and an assurance that data transmission will remain uninterrupted regardless of the heat status. Hence, Extreme Cable is a valuable solution for any high-temperature applications as it integrates strength with constant performance.

According to the details I found among credible online subjects, Extreme Cable has been developed with materials that resist heat and melting. Light cable melts even if exposed to high temperatures for a short time because its outer jacket is made from polymeric materials with high melting points. Moreover, the copper conductor embedded in the cable is also utilized because copper has excellent thermal conductivity and aids the rapid outflow of any heat that is generated within the cable. These features work together to ensure that the cable neither gets to the melting point nor exceeds it. So, searching for answers to extreme cable looks promising for applications that can be thermally challenged.

The cable gets the full benefits of using a polyurethane jacket in applications with high temperatures. To begin with, it’s useful to stress that polyurethane is a very flexible polymer that is resistant to damage and has a very high melting point, which would support the staying power of the jacket on the cable. Applying less robust materials would have resulted in deformation and gradual erosion over time. Another reason why polyurethane is preferred is its outstanding mechanical and chemical resistance, which makes it non-susceptible to damage in environments that are physically abusive or filled with corrosive elements. The fact that the jacket can maintain its elasticity even in very cold temperatures also adds to the versatility of the cable in various weather conditions. In summary, applying a polyurethane jacket is self-evident as its raison d’être is too convenient for the pedestrian use of the entire cable in high-temperature working conditions.

As the users of the Extreme Cable note in numerous reviews, the cable works without any issues, even under extreme working conditions. Many customers appreciate the cable used for long periods at elevated temperatures and functioning as designed. Reviews often cite the combination of rugged polyurethane jackets and premium copper conductors as necessary in providing this robust service even under extreme conditions. Such technical resilience is welcome, but what is even more important to users is the peace of mind it offers, knowing that Extreme Cable’s quality of construction would result in decreased servicing and improved reliability in critical applications.

Extreme Cable claims to offer its clients an outmost product warranty while standing behind the product’s reliability and quality. They provide a wide range of warranty plans; however, in this instance, they provide specific warranty against material and manufacturing defects over a longer time. The reliability of the cable is also supported by the proven reliability of the cable’s advanced materials and robust testing standards. Therefore, with Extreme Cable, customers can be assured of performance, support, and a high-efficiency level with minimum outages in several challenging environments.

Cutting-edge technology informs the implementation of stringent guidelines and constant conflict resolution through thorough compatibility testing across numerous device, system, and software classes to further product deployment. The design anatomy of the cables and the target devices was to encourage a broad range of applications, minimizing the impact of interfacial mismatches. This is achieved through comprehensive research and development initiatives commensurate with the growth of new technologies, which guarantees that all products comply with modern and current technologies and vice versa. Moreover, considering that selecting the appropriate cable type enhances cooperation and working efficiency in a wide range of settings, that type of guidance and resources to customers are also provided within the framework of Extreme Cable’s technical support.

Extreme Cable incorporates advanced materials that remain flexible and pliable even in frigid environments, effectively responding to the challenges associated with low-temperature usages. These cables are designed with specially formulated polymers that do not become brittle and remain flexible even under sub-zero specifies. Measures used in the cables’ construction to decrease the wow impact of cold include enhanced insulation and coatings that prevent cracking and offer an additional layer of protection without compromising the cable’s functionality. Such a design concept enables Extreme Cable to provide robust and reliable connectivity to sectors where the cables are used with the equipment that operates in icy environments.

Extreme Cable’s cable design includes several essential characteristics that affect their working efficiency at low temperatures and high-temperature endurance. To begin with, they use high-quality synthetic polymers that are flexible and durable while being agitated between extreme temperature variations. The insulation also prevents these materials from contacting external cold and moist air. Additionally, these cables also have a coating of expansion compounds, which reduces the amount of condensation and ice buildup. This allows the cable to maintain a consistent and functional connection no matter the extremely low temperatures or high heat the material encounters. These capabilities, achieved through plastic and material engineering, present Extreme Cable as a front-runner in developing solutions for low-temperature using cable applications. They meet the high-end requirements of aerospace, oil and gas, telecommunications, and many other industries.

The extreme cable has been devised to withstand sub-zero temperatures and harsh environments, which is a testimony to its state-of-the-art design and marketing tool. The cable is made of highly flexible and durable synthetic polymers, and together with dual-layered insulation, thermal resistance is enhanced significantly. Moreover, anti-freeze coatings are applied to eliminate moisture problems like condensation and ice build-up. Such technological innovations allow Extreme Cable to provide reliable performance, which is essential for industries that operate in extreme temperatures instead.

Контрактникам, работающим в экстремальных климатических условиях, Extreme Cable обеспечивает несколько необходимых преимуществ, в частности, способность выдерживать высокие температурные условия. First, its design also reduces unnecessary downtime and maintenance costs by sustaining optimal performance under different temperature extremes. This reliability is crucial to project completion dates and budgets, decreasing the likelihood of exceeding the initial project estimation. Second, the strong construction of the Extreme Cable products will result in fewer replacements and, therefore, less servicing even at high-temperature applications for a much longer time. Lastly, the quick installation and flexibility of Extreme Cable decreases the manpower and time required to install, which allows crews to use resources more efficiently and increases the productivity rate. These superiority factors make Extreme Cable an ideal solution for contractors who wish to get durable, efficient, and inexpensive solutions for harsh conditions.

Extreme Cables places stringent safety features for worldwide maintenance teams while ensuring there are specific industry standards. The company’s products are made out of high-strength materials that are resistant to mechanical stress erosion, thereby preserving the cable’s structure and minimizing the chances of electrification of parts. Also, part of the complete offering from Extreme Cable is safety bundles and other segments of the cable, which assist in reducing the risk of invasion and make it prone to dangerous situations, particularly at high temperatures. These improvements protect individuals and provide the reliable operation of system components employed in various operational ranges, thereby gradually establishing confidence in Extreme Cables regarding maintenance across the globe.

Extreme Cable is a leading electrical solutions provider mainly because of its state-of-the-art engineering and strict quality control processes. The cables deliver an uninterrupted power supply using materials with superior conductivity and robustness. This product line has special shielding against electromagnetic interference that minimizes signal loss, thereby increasing the system’s reliability in demanding conditions. In addition, stress testing is carried out to ensure performance in several situations, and in doing so, the company makes sure that the Extreme Cable products are of good quality and standardized. These factors make Extreme Cable one of the best electrical cable manufacturers with temperature control measures even in harsh situations.

A: Extreme Cable, however, provides better performance and flexibility and is completely different from wires. It has advanced conductor technology, has much better insulation, and is way more durable, making it appropriate for harsh working conditions. This cable can sustain great power loads and higher data transfer, so diverse applications can be used with this cable, starting from devices that work on 10g SFP technology and ending with something much heavier.

A: Custom-length cables can be made at any length suitable to the client’s needs. However, 3.3ft and 10ft are some of the available lengths for the Extreme Cable. It can reach further lengths depending on the cable type and its intended use, but generally, as a rule, it should offer longer runs without any distortion or signal degradation. I would suggest that a person contact the manufacturer for guidance on the length they require.

A: Yeah, that’s true; Extreme Cable has male connectors for those who require them and provides male connectors among its vast range of connectors. Such connectors can provide alluring devices to a wide range of equipment with enhanced performance. If you need USB, Ethernet, or connectors for another kind of device, Extreme Cable provides male connectors for all such devices and ensures that the connection is tight and proper.

A: Extreme Cable has an advantage in using the best cables as we know that their operational performance level is highly remarkable, especially in high-temperature environments. Its construction allows for using one, two, or three copper aluminum or even fiber optic conductors, depending on the specific cable. Such heterostructure conductors also optimize thermal issues, suppress noise, and manage high power loads, making them best suited for a range of devices from the extreme cable for data centers to a MacBook Pro.

A: Indeed, many developments and advances provide adequate power and data transfer, which is possible using the Extreme Cable. Selected versions contain a 2-wire power delivery system, while others have several conductors allowing power transmission and data. This capacity of the Extreme Cable gives it an edge for situations where speedy data transfer and efficient power delivery are needed, such as Extreme Networks installations or other challenging places.

A: Extreme Cable is superior to conventional electric cables in several ways. For instance, it is more robust, requires more power, and almost completely shields from electromagnetic interference. Extreme Cable also enables enhancement in flexibility and bend radius, enabling it to be used in places that would have been difficult otherwise. With all these advantages, it is well suited for tasks requiring consistent effectiveness under harsh circumstances.

A: Yes, of course. Since Extreme Cable was created while keeping portability in mind, it can easily be used with portable devices such as laptops, smartphones, and tablets. Its unique flexibility will enable it to endure constant plugging and unplugging without fear of damage. While traveling, it can connect to a MacBook Pro or other portable devices without a hitch.

A: Extreme Cable, for one, has some critical features that set it apart from conventional cables. These include increased robustness for outdoor use, greater electromagnetic shielding, enhanced connectors for connection reliability, and improved conductor technologies for better signal transmission. What’s more, there are times when Extreme Cable is likely to have greater bandwidth and power transmission capacity, which makes it applicable to various areas.