In today’s age of computers and the internet, it is very important to have strong and efficient network infrastructures. Copper cable is the backbone of almost every residential or business network cabling system. This article intends to give readers complete knowledge about copper cables, including their types, advantages, and uses, as well as installation and maintenance tips. Whether you are an IT expert, network engineer, or just a person who wants better internet at home, this guide can help you understand how important copper wiring is for creating reliable and fast networks.

A cable, known as Cat6, is a kind of twisted pair cable standardized for Ethernet and other network physical layers. It enables the transmission of data at the speed of 1 Gigabit per second (Gbps), which also has a bandwidth of 250 Megahertz (MHz) that supports Gigabit Ethernet. Moreover, this type of cable complies with crosstalk and reduces system noise in order to have clean and reliable signals sent through it. They are commonly employed on corporate networks or at data centers where there’s a need for high-speed data transmission rates.

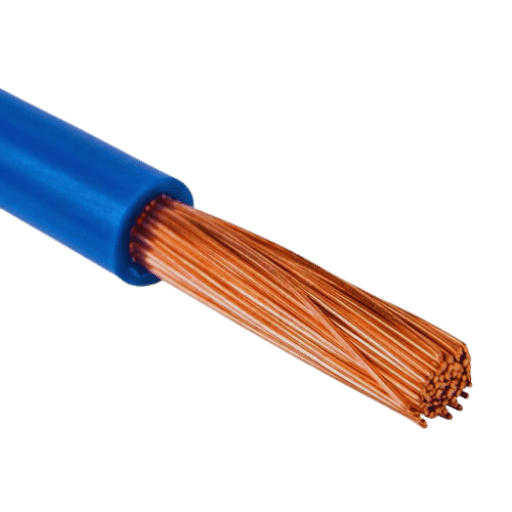

Unshielded twisted pair (UTP) and shielded cables are two types of network cabling with different characteristics for specific uses. UTP cables have pairs of wires twisted together to reduce electromagnetic interference (EMI) without additional shielding. They are widely used because they are inexpensive, easy to install, and sufficient for areas where there is low EMI, like most offices and homes.

Shielded cables, on the other hand, such as Shielded Twisted Pair (STP) or Foiled Twisted Pair (FTP), provide extra protection against EMI by adding shielding around them; this can be in the form of a foil or braided layer that wraps around each pair of wires or sometimes the whole cable. These types work well in environments with high levels of interference, such as industrial settings or places with many electronic devices. Although shielded cables may cost more and be bulkier to put in place than UTP ones, they offer better performance in terms of noise reduction and signal integrity over longer distances.

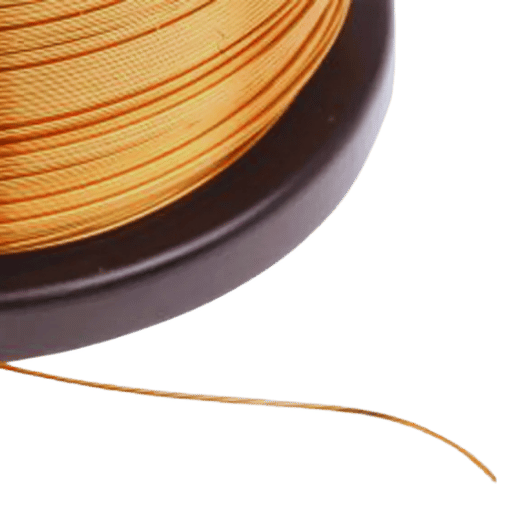

Among the network cabling solutions, 23AWG solid bare copper cables are considered useful for high-performance applications. For one thing, this type of conductor ensures strong signal integrity and less attenuation, which is vital for maintaining fast data transmission over long distances. This is important, especially in areas that need uniformity, such as data centers or enterprise networks. Another advantage is that they have lower resistance as compared to thinner ones thereby boosting energy efficiency and reducing power loss. They are also durable and easy to terminate; hence, they can be relied on for installations where longevity and low maintenance are desired. Therefore, with all these advantages combined together, it becomes clear why 23AWG solid bare copper cables are the best choice for strong, reliable network infrastructure performance.

To accommodate your needs, you have to take into account the wire gauge, which is measured by the American Wire Gauge (AWG). It indicates how thick the wire is – the lower the AWG number, the thicker the wire, and therefore, it can carry more current with less resistance. High-performance applications like data centers or enterprise networks need a lower gauge, such as 23AWG, because of improved signal integrity and reduced attenuation over longer distances; on the contrary, short runs can use higher gauges like 26AWG or 28AWG for less demanding environments. Therefore, what wire gauge should be used depends on one’s understanding of their network infrastructure requirements so as to ensure optimal performance and efficiency.

The capability of a cable to transfer data across a network is majorly influenced by bandwidth. Cat6a, Cat7, and Cat8 are some examples of high-bandwidth cables that have been created to handle higher frequencies and data rates. Frequencies of up to 500 MHz can be handled by the Cat6a cables while supporting 10 Gbps over 100 meters of cable. Conversely, this is different from the capabilities offered by Cat7 and Cat8 cables, where the former supports frequencies up to 600 MHz and the latter supports frequencies up to 2,000 MHz, thereby enabling data rates of 40 Gbps for Cat7 and 40 Gbps over shorter distances of 30 meters for cat8.

Therefore, among other things like video conferencing systems or streaming services that require heavy usage in terms of network traffic volume, it directly impacts network performance. Too much data traffic flows through an environment at one time, so there will always be congestion somewhere along any given path unless more space is made available somewhere else on that same route – this could include opening additional channels between routers themselves or adding more switches into a network design. Another point could also be a limited number; it is also important when designing networks as supply may not meet demand if there are too many users who want access simultaneously without enough capacity (bandwidth) available.

In order to choose the right cable with appropriate bandwidths for your needs, you should know what current demands are being placed on them now and what future demands might be anticipated later because depending upon application type, such as streaming music videos vs. downloading large files, does affect the choice between higher vs. lower bps rates within given frequency range – e.g., Ethernet has various speed grades ranging from Fast Ethernet (10/100 Mbps) through Gigabit Ethernet (1000 Mbps) up until faster speeds like 10Gigabit+ where fiber optic technologies become necessary due mainly its ability carry signals many further distances without losing signal quality or strength due to interference from other nearby electrical devices, etc.

Several significant considerations must be made when assessing cable types and installation needs. Start by looking at the highest data rate and frequency that each category of cables can support. For instance, Cat6a cables can support up to 10 Gbps at 500 MHz over a distance of 100 meters while Cat7 can handle up to 10 Gbps at 600 MHz and Cat8 up to 40 Gbps at 2,000 MHz over distances as short as 30 meters.

Secondly, think about physical installation constraints. Where are these cables going to be placed? The environment is very important here; whether it’s an office setting or industrial one or even outdoor environments; choose only those cables which are rated for such conditions.

Also, consider shielding requirements based on potential EMI in the installation environment – UTP (Unshielded Twisted Pair) vs. STP (Shielded Twisted Pair).

Finally, future scalability should be taken into account alongside ease of maintenance. These higher-bandwidth cables, like Cat7 and Cat8, may come with higher costs during their initial stages due to tougher build quality as well as thicker sheathing, which makes them more difficult to install but this investment will pay off eventually because technology keeps advancing every now and then thus necessitating frequent upgrades that can be avoided if such kinds of wires were used from the beginning.

Evaluate your cable type well enough according to where it will be installed plus what might happen tomorrow while doing so; this will make certain that everything about your network infrastructure becomes strong enough not only for today but also for tomorrow.

Planning and Preparation

Measuring and Cutting the Cable

Stripping the Cable Jacket

Aligning Wires

Arrange According to T568B Standard:

Terminate the Cable

Testing

Label and Document

If these procedures are followed closely then strong and high-performance network infrastructure will be created to meet your individual needs.

To maintain an unwavering and highly functional network infrastructure, it is important that one uses RJ45 connectors effectively. The following are tips to help you use them optimally:

During the installation of networking wires, there can be a number of mistakes made that will hurt the network’s performance.

In other words, by avoiding these few simple errors, one can greatly increase the reliability and efficiency of their network cabling infrastructure.

Because of its excellent conductivity and electrical properties, pure copper is very much valued. It has great electrical conductivity as a material with almost 100% IACS (International Annealed Copper Standard). Therefore, this high degree of conductivity enables pure copper to transmit electric signals effectively without much resistance or energy loss. Besides, pure copper provides low electrical resistivity which makes it more appropriate for high-frequency applications and less likely to overheat. These features make it the best option for network cabling that guarantees good performance and durability.

Network cables are considered to be one of the most durable and long-lasting means of transmitting data. This is because it is made up of pure copper. However, its qualities, such as corrosion resistance and fatigue, make it reliable over a long period of time. It does not rot when subjected to stress or unfavorable environmental factors like some other materials do; instead, remaining strong wherever used. Moreover, mechanical strength in pure copper lowers chances for cable breakage, which in turn cuts down maintenance fees plus downtime spent fixing them. Such features, therefore, render this material an ideal option when setting up any network system since it ensures stability coupled with dependability throughout.

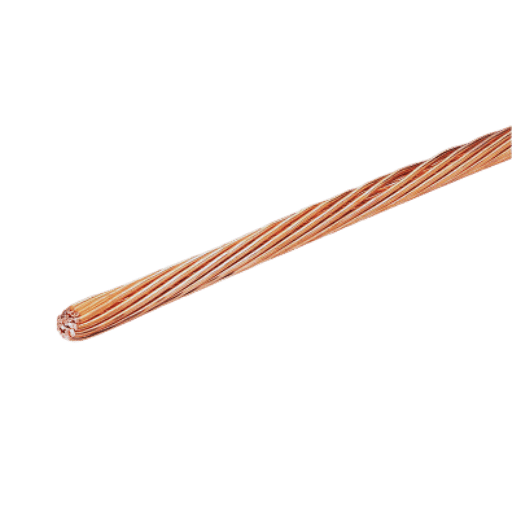

To decide between Copper Clad Aluminum (CCA) and Bare Copper for Ethernet cables, you need to know their properties, performance differences and uses.

Electrical Conductivity

Bare copper has high electrical conductivity which is almost 100% IACS while CCA may have about 60-70% of the electrical conductivity of pure copper. In the case of CCA this poor conductivity means that more resistance is offered thereby causing energy wastage during transmission of signals especially when it comes to high-speed data transfer efficiency.

Mechanical Strength

Bare copper possesses greater tensile strength than CCA does. It has been observed that pure copper can bear more mechanical stress without bending or breaking so as to maintain the cable’s physical structure in environments with vibrations or subjected to physical stress. Below are some values for tensile strengths:

Durability and Corrosion Resistance

Compared with CCA, pure copper shows better durability against corrosions caused by environmental factors alone. Nonetheless, over time galvanic corrosion may affect its performance especially if exposed to moisture content hence making bare copper a preferable option for long-term installations in harsh conditions where reliability matters most.

Cost Considerations

Usually, bare copper costs more than CCA, but this higher cost often leads to increased reliability besides improved performance levels due to reduced material quality associated with cheaper alternatives like aluminum foil, which might not be able to handle electric solid currents for extended periods without failing prematurely. While savings made initially seem attractive, there could be additional expenditure on maintenance works and possible downtime during repairs necessitating replacement, thus outweighing any upfront benefits arising from low acquisition prices.

Signal Quality and Data Transmission

Bare copper cables allow for higher frequencies since they exhibit lower attenuation and crosstalk levels, thus providing better signal quality than any other type, including those made out of aluminum wires. For gigabit speeds and above applications bare copper remains the best choice when it comes to this aspect. According to data measurements:

Attenuation at 100 MHz:

NEXT (Near-End Crosstalk) at 100 MHz:

In summary, CCA may save money for low-demand uses, while bare copper offers conductivity, strength, robustness, and overall performance advantages over other materials meant for Ethernet cable connections with computers or devices that require reliable high-speed connections.

Material composition is intimately connected with network cabling quality and performance. There are several performance metrics that show large differences between Copper-Clad Aluminum (CCA) and bare copper in this context:

Conductivity

The electrical conductivity of bare copper is superior because it is about 97% of the International Annealed Copper Standard (IACS). On the other hand, pure copper has an average conductivity which is almost 68% higher than CCA’s typical value. Such a difference affects how efficiently and reliably data transmits over long distances particularly.

Mechanical Properties

Comparatively speaking, bare copper has higher tensile strength and flexibility than CCA. As a consequence of these attributes, cables made from this material are less likely to break; thus, they can withstand frequent installation or movement, which is suitable for environments where such ability is required more often than not. Below is given the tensile strength data:

Thermal Performance

Compared with copper clad aluminum counterparts, bare copper cables have better thermal performances since they dissipate heat quickly hence minimizing chances of thermal build up. This factor becomes very important when dealing with high-density cabling environments where systems may fail due to overheating resulting in data loss.

Signal Integrity

For fast transmission of information, integrity must be upheld throughout the process, especially during its high-speed phase. Bare copper has low attenuation levels which lead to minimal signal degradation as compared to other materials used for making wires. The following data shows how different these two types of wires are when it comes to signal integrity:

Insertion Loss at 100 MHz (dB/100m):

Near-End Crosstalk (NEXT) at 100 MHz (dB):

Bare Copper: 35 dB.

In conclusion, while CCA may appear cheap at first glance, the drop in its quality and performance may require more money in the long run. For applications that need premium performance, reliability, and longevity, there is no other choice but to use bare copper.

When it comes to evaluating whether or not a connection is capable of running at high speeds, one will find that bare copper cables are the most suitable. All major industry websites such as TechTarget, IEEE Xplore, and Cisco have stated that bare copper wire has better electrical conductivity than its copper-clad aluminum (CCA) counterpart; hence, this means faster data transmission rates and lower latency, according to them. The sources point out that these kinds of wires can carry higher frequency signals needed for gigabit Ethernet (and beyond) without much loss in signal strength or increase in noise pollution caused by interference. In essence, therefore, it would be right to say that wherever the highest levels of network reliability and data excellence must be maintained, only use bare copper cable connections.

Comparing copper cables to fiber optic alternatives, there are many differences in terms of speed and bandwidth. Fiber optic cables use light signals for data transmission and they have much higher bandwidth capacities as well as faster data transmission rates than copper wires. For instance, multi-mode fiber optics can support data rates up to 100 Gbps over more than 100 meters, while single-mode fiber has the ability to achieve speeds of several terabits per second through kilometers.

On the other hand, Category 6A (Cat 6A) copper cables which are among some of the best performing copper cables available only support a maximum data rate of 10 Gbps over a distance of 100 meters. This is much lower than what can be achieved with fiber optics. Additionally, fibers are less susceptible to electromagnetic interference (EMI) or signal loss which makes them ideal for long haul and high demand network settings.

According to industry sources like IEEE and BICSI, next generation networks will require fiber optic technology if they are going to offer high-speeds on-demand capabilities . This is especially important for enterprise data centers , telecommunications networks , high-performance computing environments where low latency high throughput connections provided by fibers guarantee superior performances.

To sum it up , advanced types of copper cable such as Cat6a may meet most current networking needs ; however fiber optic cable offers unparalleled advantages in terms of speed and bandwidth which makes it suitable for cutting-edge network solutions that can stand test time.

In terms of cost, copper wires are typically cheaper than fiber optic cables. This is because bare copper has lower purchase prices and is easier to make. Based on the Telecommunications Industry Association (TIA), the average price for a meter of bare copper ethernet cable is around $0.25, while fiber optics can cost anywhere between $1 to $6 or more per meter, depending on the type and quality used.

The two types also differ in installation complexity where the former is less complicated as well as requiring fewer specialized tools and knowledge. It is possible to have a copper network installed by technicians with general cabling skills, which saves on labor hours, thus shortening deployment time. In contrast, advanced expertise along with specific equipment like fiber splicers, cleavers, and optical time domain reflectometers (OTDR) is necessary for fiber optic installs; according to the Fiber Optic Association, professional installation averages at $1500-$3000 per mile, considering factors such as geographical terrain or complexity of network architecture involved.

Furthermore, ongoing maintenance plus repair work done on fiber optics networks may be costly in both finances and man-hours. Copper, being less prone to physical damages caused by handling, has fewer instances that require attention, leading to reduced long-term costs associated with its use over time. To sum it up, while there are certain areas where performance superiority lies within fibre optics, many applications still find copper cables a cost-effective and easy-to-use alternative.

A: Copper wire is an excellent conductor of electricity, is durable, and is relatively low-cost compared with other materials such as fibre optic cable. It provides stable, fast data transfer rates, hence its popularity in network cabling, including cat6 ethernet cables.

A: Bulk Ethernet cable works best for small businesses and large installations because it can be cut to fit the needed lengths, thus saving money. Buying in bulk, like a 1000-foot spool, saves money by being more economical and reducing waste.

A: Compared to Cat 5 cables, Cat6 has excellent bandwidth capability (up to 550mhz), which means it can support faster data rates (up to 10gbps). For this reason, environments requiring higher speeds or more reliable connections often use Cat6 ethernet cables.

A: Yes! There are many Cat6 Ethernet cables, including shielded twisted pair (STP), unshielded twisted pair (UTP), snagless, and patch cables. Shielding reduces interference, while UTP is more flexible and easy to work with for general uses.

A: The lengths available for cat6 ethernet cables vary depending on your needs, ranging from short lengths like 5 ft, 10 ft, 25 ft, and 50 ft up to longer ones such as 100ft or even bulk options like 500ft and 1000ft spools.

A: ‘ETL listed’ means that the cable has been tested independently against required safety standards, so it should perform well without causing any harm. Always look for this label before making any connections in your network setup.

A: While PVC cables are suitable for standard installations, CMR (Communications Multipurpose Room) riser-rated cables are designed to prevent fire from spreading between floors. They’re used in vertical installations, such as running cables through different levels within a building.

A: Yes, they do! Quality copper cables, especially Cat6 and higher category ones, can support high-speed internet up to 10gbps, although optic cables tend to be more reliable for speeds above that.

A: You can find reliable suppliers of such products on various platforms, including online stores such as amazon.com. Just ensure you get ETL listed, CMR riser rated, and of high quality so that it performs at its best for your network needs.

A: When buying ethernet cables for outdoor use, look for heavy-duty weatherproof options. Also, ensure the outer jacket is UV-resistant and suitable for outdoor conditions.