With utmost speed and insight, Fiber optic technology has transformed the transmission of data across industries. Often forgotten among the innovations is an essential component: ceramic sleeves. This component is famous for its precision and durability, which prove vital to maintaining stable connections and optimal performance in fiber optic systems. This article seeks to assist in understanding why ceramic sleeves are still deemed critical in high-precision applications, investigate their distinctive traits, and understand how their resilience enables modern telecommunications advancements and other disciplines.

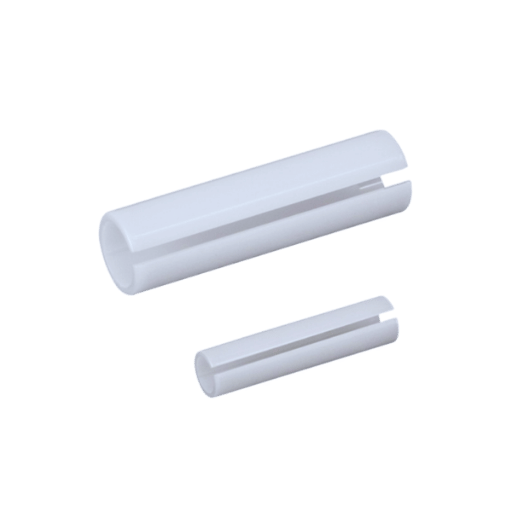

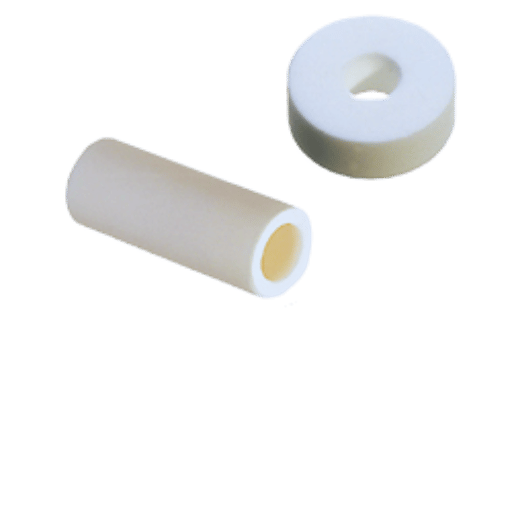

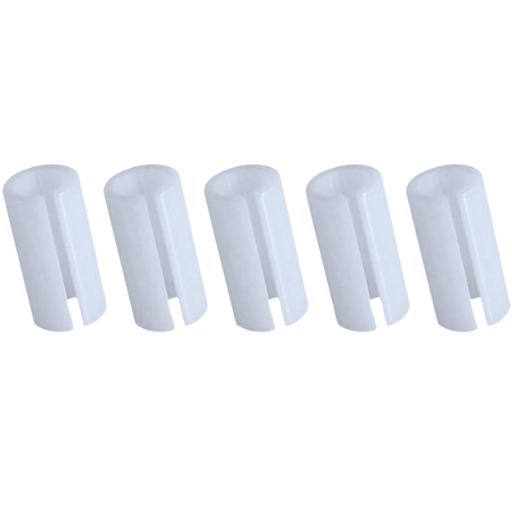

A ceramic sleeve is a small, cylindrical element employing zirconia, which is a strong, low thermal expanding ceramic used in a fiber optic system to locally align and hold the interface between the fibers or connectors. It ensures precise alignment to minimize light loss during transmission. Specifically, the ceramic sleeve’s applications include gripping the ferrules of two fiber optic connectors and holding them in place so that proper core-to-core alignment is attained to facilitate maximum signal transfer across the interface. As a result of its strength and accuracy, it is instrumental in ensuring dependable efficiency in modern high-density, high-speed networks.

Zirconia is noted for its thermal stability and wear resistance, and it is a compound that is highly durable as well. It is also capable of withstanding mechanical and thermal stress. The cross-section of a ceramic sleeve is a perfect alignment of an inner cylinder with close-fitting tolerances for optical fiber precise interlocking. This design greatly reduces the likelihood of signal loss by retaining the ferrules and ensuring core-to-core contact. Because of the then all of the factors stated expensive materials’ robustness, ceramic sleeves are best suited for use as support structures in high-performance fiber optic links for extreme conditions environments.

Optical fiber sleeves utilize ceramics, which allow accurate placement of components thanks to the advanced construction and material characteristics that define them. The manufacture and use of ceramic components greatly increase the precision of alignment of optical ferrules due to the wonderful matchmaking capabilities of these materials. With such clear match formation, the loss during power exchange in a signal cavity is tremendously reduced. The general requirements set for loss under optimal conditions are up to 0.3 dB. The sleeve significantly assists in attaining this value.

Disconnected components oftentimes lead to damage and failure, which can be caused due to thermal expansion or increased operational temperatures. This makes materials such as zirconia, which have extreme durability as well as resistance to heat, perfect for use in sleeves. This construction enables optimal alignment in a wide range of operating conditions, from standard environments to more challenging ones, such as telecommunication centers and high data speed networking centers. Both manufacturing and low thermal expansion of sleeves lead to increased return loss, which is necessary throughout the entire network. These indicators display the quality of modern fiber optic systems as well as allow claiming pos candidates for new technologies.

Ceramic sleeves ensure optimal signal transmission with minimal degradation while meeting the rigid requirements of high-speed optical networks by focusing on core alignment and environmental resilience.

Ceramic sleeves are essential for enhancing fiber optic alignment due to the stability and precision with which they position the ends of the fibers. The sleeves high rigidity and low variability guarantees perfect core alignment, which minimizes insertion loss and augments signal strength. Moreover, their mechanical properties along with resistance to temperature allow diverse environmental conditions without compromising performance. Because of those characteristics, ceramic sleeves are vital for dependable and effective connections in sophisticated networks of optical fibers.

Compared to metals, ceramic materials have a much higher thermal resistance, so they are better suited for fiber optic sleeves used in more extreme conditions. Zirconia and alumina ceramics maintain their structural integrity and mechanical performance over a wide range of temperatures, enduring up to 1000°C and more. In addition, these materials exhibit low thermal conductivity of about 2–4 W/m·K, ensuring minimal heat transfer and maintaining stability in optical systems.

On the other hand, some metals such as stainless steel are more durable but have lower thermal resistance and higher thermal conductivity. The thermal conductivity of stainless steel is about 16 W/m·K, and it endures 500-800°C depending on the alloy grade. Higher thermal conductivity tends to augment thermal dissipation which causes expansion or alignment problems in sensitive optical devices.

This increase in resistance and disparity in thermal conductivity demonstrates why ceramic materials are more widely used, especially in high-performance and high-temperature conditions. Ceramics are known to withstand high thermal expansion while ensuring precise alignment of optical fibers, which maintains signal quality even at varying temperatures. These features highlight their importance in modern fiber optic communication systems.

Precision ceramics provide critical enhancements in sophisticated systems as they are indispensable in advanced technological integrations. The following aspects summarize the primary benefits of their material properties:

These factors combined explain why ceramics outperform other alloys in high-precision tasks that require mechanical reliability, thermal shock resistance, and chemical balance. Their continued integration into modern systems propels developments in optical communication, aerospace engineering, and semiconductor industries.

As a result of its natural ability to withstand wear, high temperatures, and chemical corrosion, ceramic has greater durability than plastic. Unlike plastic, which can soften or disintegrate when subjected to heat or harsh chemicals over time, ceramic preserves its shape even under the most severe conditions. Furthermore, due to durability, ceramic is more resistant to scratching and change in shape which extends its service life in harsh working environments. These characteristics make ceramics perfect for high-performing and reliable applications.

Knowledge of the precise specifications for single-mode and multimode fibers is fundamental when choosing a ceramic sleeve for the fiber optic system. Single-mode fibers have a core diameter of about 8 to 10 microns; they are made with greater precision to accommodate long distance, high bandwidth communication. A single-mode application requires a ceramic sleeve with an inner diameter tolerance of about ±1µm to minimize the loss of signal transmission.

Multimode fibers are used in shorter distance communications, like those within data centers, and are made with core diameters between 50 and 62.5 microns. These fibers, compared to single-mode fibers, are less sensitive to core alignment discrepancies. The precision standards for the sleeves could be less stringent because of the increase in core diameter.

APC or UPC connectors are used for single-mode systems. These types of connectors require fiberglass polishing on the sleeves to achieve the necessary optical performance. The PC connector is used in multimode systems, and the sleeve design captures the less demanding performance parameters.

Taking these aspects into consideration, it is critical to assess the particular tolerances, specifications, and types of connectors of your system so that you are able to choose a ceramic sleeve designed for single-mode or multimode optical fibers. The correct selection can improve the efficiency and dependability of the fiber optic network by significantly minimizing insertion and return losses.

Correct dimensions along with matching specifications must be maintained for optimal functioning of fiber optic networks. In my view, this means diligently checking the mesh fit of the ceramic sleeve to the fiber and connector types used. Exact alignment minimizes signal attenuation while guaranteeing dependable connections which is critical in network continuity and operational efficiency.

Combined approaches to interpret product description texts for different manufacturers have situational level focus which takes into consideration of specific differences in idiolects, lexicons, and working standards of description, multi criterion analysis, testing methodologies, product functions, structures and performance standards.

Variations oftentimes appear due to differences in design protocols, materials, quality, and testing procedures, which directly affect the functionality within a specific application. For instance, inserting loss for fiber optic connectors from Manufacturer A may be described as “<0.25 dB” for lab conditions, whereas Manufacturer B may show it as ‘<0.30 dB” for contractions under practical settings such as higher temperatures or vibrations.

In addition, most of the specification documents relevant to materials also mention the performance or durability targets of a component. A ceramic ferrule may be rated with different tolerance levels like plus minus 0.001 mm or plus minus 0.003 mm and so on. The former holds more rigor on control of achieved alignment precision. Such variations may be minute in nature but could lead to dramatic differences in overall network performance, for instance, in high-bandwidth applications.

Finally, as in the case of “return loss” and “back reflection,” some metrics may be used interchangeably without regard for their distinct definitions in some instances, highlighting the need for precision in understanding descriptors. For the purposes of streamlined and accurate engineering comparisons, it helps to gather all performance data, compliance documents, and operational pertaining to claims offered by each manufacturer. This aids in compatibility, as well as in the development of inexpensive and high-performing optical devices.

When searching for reliable suppliers of ceramic sleeves, pay attention to the following reputable platforms:

These vendors are trustworthy and previously verified for quality assurance, making them reliable procurement options.

The detailed reviews and customer ratings of various suppliers of ceramic sleeves assist in assessing the credibility of the suppliers. For example, users of Mouser Electronics commend their overall services and documentation of products, which has earned them a customer satisfaction score of 4.8 out of 5. Also, Farnell has received good customer reviews for sound customer service and correct order placements, with a rating of 4.7 out of 5 on several review websites.

DigiKey Electronics garners praise from professional buyers for transparent pricing and an intuitive website, which explains their high 93% positive feedback rating. On the other hand, the suppliers on Alibaba have received positive customer feedback due to their bulk supply; however, the ratings given tend to differ greatly from supplier to supplier, viciously needing the reader to pay close attention to the reviews. Stronger ratings are often attributed to maintained verified certifications, active dialogue, and emails, and help that is quick to answer or attend.

As mentioned above, it is clear that combining insights from the customers and technical specifications benefits aiding businesses in procuring high-quality ceramic sleeves suitable for their operational standards.

In the case of purchasing ceramic sleeves, a supplier is to be chosen based on their overall credibility, their timely delivery, the cost-effectiveness of their services, and the reliability of their logistics. Always use suppliers with tracked deliveries to maintain visibility throughout the shipping process. Please check the estimated delivery dates and ascertain whether express services are available for critical needs. Also, assess marking accuracy concerning the prevention of loss or harm during shipping. Collaborate with suppliers who have well-defined policies on returns or replacements concerning shipping mistakes or item defects incurred.

Ceramic sleeves have an important function in the alignment and coupling of fiber optic connectors in assemblies and adapters. These parts are specifically manufactured to align the precision cores of fiber optic cables and, thereby, achieve low insertion loss and high return loss, which are needed for the effective transmission of optical signals. Ceramic sleeves, because of their high precision, ensure optimal signal integrity by avoiding uncalibrated shifts, which may reduce performance.

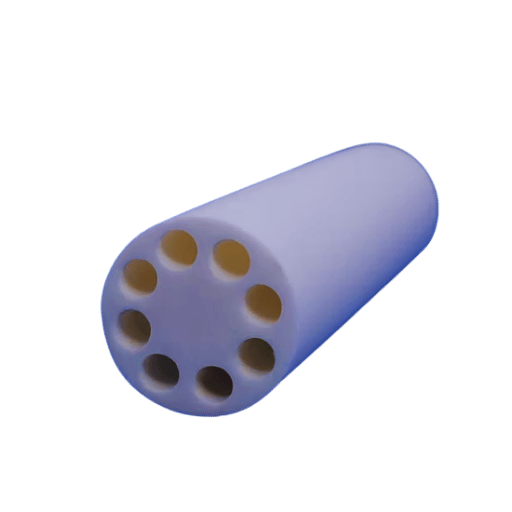

The durability and qualitative reliability of the components in fiber optic networks is guaranteed due to the use of zirconia ceramic, which possesses exceptional hardness with precision machinability. As per standards, alignment accuracy in ceramic sleeves often achieves tolerances of ±0.001 mm, which is more than sufficient for many applications requiring high-speed communication like 5G networks and data centers. Moreover, ceramic sleeves are crucial for the support of Multi-fiber Push-On (MPO) connectors, which are critical in high-density fiber connection management for modern telecommunication infrastructures.

Enhancements in ceramic sleeves have improved their suitability for harsh industrial and outdoor environments by increasing their thermal stability and wear resistance. Lastly, these features and the propensity to model them to numerous types of connectors underscore their strategic importance in the development of durable and effective fiber optic networks.

Ceramic sleeves are crucial in applications requiring high precision and strong endurance because they are able to withstand severe thermal and chemical conditions. Below is a detailed summary of their applications in different thermal and chemical settings:

High-Temperature Fiber Optic Systems

Corrosive Chemical Environments

Underwater Cables and Submarines

Power and Energy Sectors

Defense and Military Applications

Ceramic sleeves have proven to be effective in ether optic connections and enduring harsh thermal and chemical environments. This speaks to the adaptability of the material.

The uninterrupted functioning of fiber optic networks heavily depends on ceramic sleeves. Their turning performance gives them unparalleled proficiency in environments where wear, thermal stress, and chemical damage are prevalent. Sustaining strong connections over extensive periods are possible with these parts, and as such, maintenance needs are subsequently also reduced. These components are critical for industries that depend on sustained communication systems, systems like data centers, telecomunications, industrial automation and other areas exercise serval depend on communication in relay data and vice versa.

A: A ceramic sleeve is an important feature of a fiber optic connector, as it provides a precise alignment for the respective optic fibers. It is important in fiber optic connections as it guarantees the least possible loss of signal and maximum reliability and dependability, which is ideal for high-performance data transmission.

A: Compared to other materials, such as plastic or metal, ceramic sleeves are used in fiber optic adapters due to their enhanced durability, precision, and thermal stability. They also ensure better alignment of the fiber cores which lower the insertion loss and increases return loss essential for signal integrity in fiber optic networks.

A: Ceramic sleeves are said to come in various sizes. For LC connectors, the common inner diameters range up to 1.25mm whereas for SC connectors it can go up to 2.5mm. The outer diameter and length depend on the specif type of connector and application requirements.

A: In the case of a ceramic sleeve, ensure that the fiber optic end face is clean first. Then, cleave the fiber to the proper specifications. The next steps are to take the sleeve and slowly guide the fiber into it without applying unnecessary force or damaging it. Finally, for proper alignment use either a fiber optic alignment tool or an appropriate tool of your choice that goes in accordance with the instructions of the connector type that you are using.

A: Fibercables.com believes that ceramic sleeves should come in a kit which would include most parts that could be used for installation. In other words, specialized cleaning and polishing tools and sleeves are available as kits to help provide efficiency to maintenance and repair projects using fiber optics. Kits are incredibly useful for technicians working on numerous different fiber projects.

A: Regular maintenance of ceramic sleeves in fiber-optic adapters involves cleaning them with specialized tools like foam swabs or cleaning cassettes. Also, air that is compressed is not suggested for such tasks because they can pollute the region. Cleaners such as isopropyl alcohol and wipes that do not leave residual fibers can be helpful when cleaning tough debris. As with all cleaning, make sure to follow established procedures for cleaning to avoid damaging the sleeve or the ends of the fiber.

A: Certainly, ceramic sleeves are applicable in both simplex (single fiber) and duplex (dual fiber) connections. Typically, in duplex adapters, two ceramic sleeves are fitted adjacently to take care of the pair of fibers. That is the reason ceramic sleeves can be utilized in a variety of fiber optic networking applications.

A: Both components are essential, but a ceramic sleeve belongs to the part of the adapter that joins two connectors and aligns them, while a ceramic ferrule pertains to the connector itself that guides and secures the fiber end. In this case, the two mounting devices used for the ferrules of the two connectors serve as an adapter sleeve, which guarantees foundational alignment of the fiber cores to provide maximum signal power through the system.

A: Ceramic sleeves minimize insertion loss because they enable remarkable core alignment. Their precision ensures that the fiber ends are perfectly aligned, that is, optimized as to their positions to minimize inter-fiber gaps and, thus, increase signal transfer efficiency at the point of connection. This precision is important for high-speed data transfer applications because the functional signal limit must be preserved in order to maintain its reliability.

A: Ceramic sleeves have a very high tolerance to temperature changes and harsh conditions, which makes them suitable for many applications. However, in extreme conditions like high vibration or cyclic mechanical conditions, proper covers for the connectors and the adapters should be designed and utilized. Regular maintenance tasks like cleaning should also be undertaken in order to maintain performance in harsh conditions.

1. Driving Out Force of Shaft Failure Position in Preventing Coming Out Failure of Shaft within Shrink-Fitted Sleeve Roll with Ceramic Tools

2. Effect of a Change of Procedure for Joining Ceramic Head with Adapter Sleeve on the Stem Taper for Revision: An Experimental Study

3. The Characterization of Porosity and Externally Solidified Crystals in a High-Pressure Die die-casting hypoeutectic Al-Si Alloy Using a Newly Developed Ceramic Shot Sleeve

4. Prevention of Coming Out by Stopper for the Shrink Fitted Sandwiched Shaft from the Ceramic Sleeve

5. Coming Out of Shaft from Shrink Fitted Sleeve of Ceramic Failure Analysis

6. Ceramic