Every part of a network infrastructure is important individually; a Cat6 RJ45 Keystone Jack is not an exception. This device maintains clear connection points and fast data transfer within both personal and professional networks, as it includes all ethernet and computer wiring configurations. With so many choices available, how do you know which one to go with? This article touches on every detail of Cat6 RJ45 keystone jacks and their specifications with the reasons that demonstrate their value in refining network performance. This article is meant for everyone, IT professionals, individuals, and even homeowners wanting to improve their network.

What Are the Key Features of a Cat6 Keystone Jack?

Keystone Jacks Cat6 are vital for high speed and reliability of connection. They have specific features such as:

- Performance– High-Speed: Guarantees data transfer for modern networks up to 1 Gbps, includes operating frequency of 250 MHz. Efficient connectivity is available at higher levels in modern networking.

- Universal Compatibility: Meant for peripheral devices like patch panels, wall plates and even surface mount boxes. These are versatile and can be used almost anywhere.

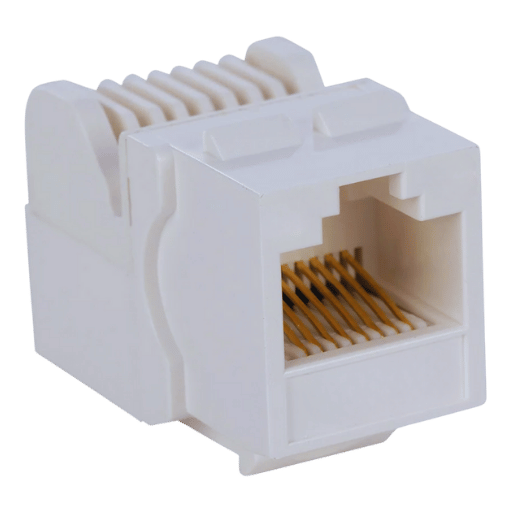

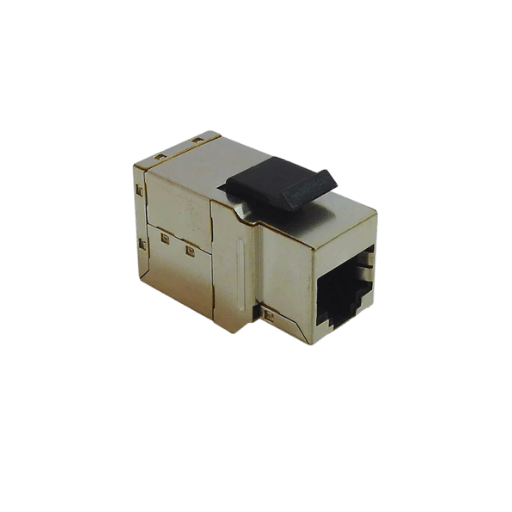

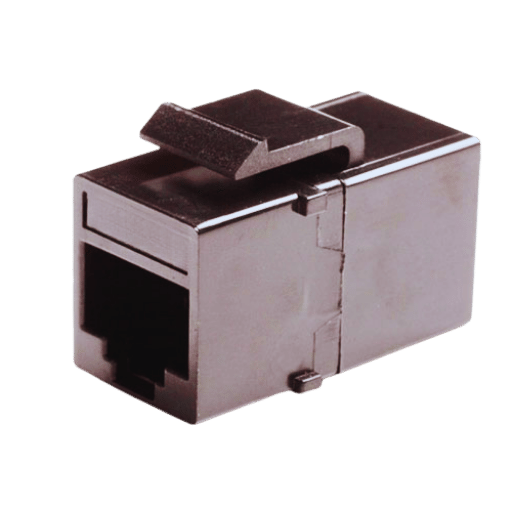

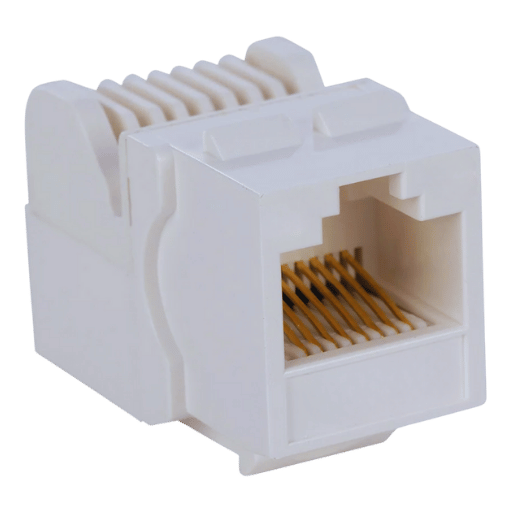

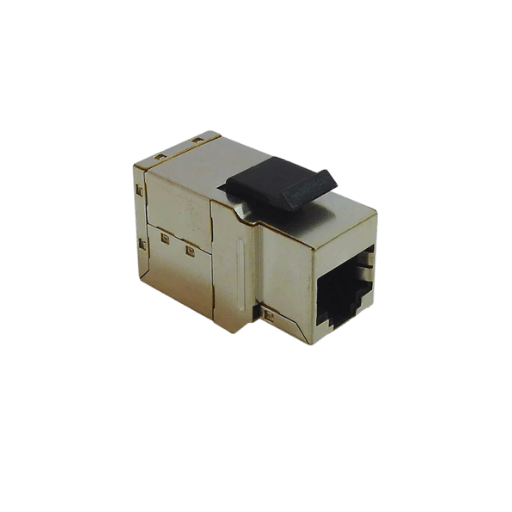

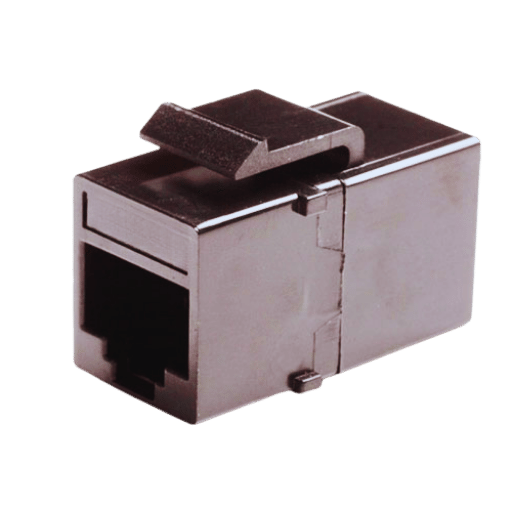

- Enhanced Signal Integrity: Reduce interference and improve signal quality using advanced shielding and gold-plated contacts.

- Toolless termination: Simplified toolless design in many Cat6 keystone jacks enables installation expediently.

- Durability: Exactly crafted and constructed from high quality material in residential areas and commercial setting gives the jack extreme longevity.

Cat6 keystone jacks are better than others because they optimize network systems.

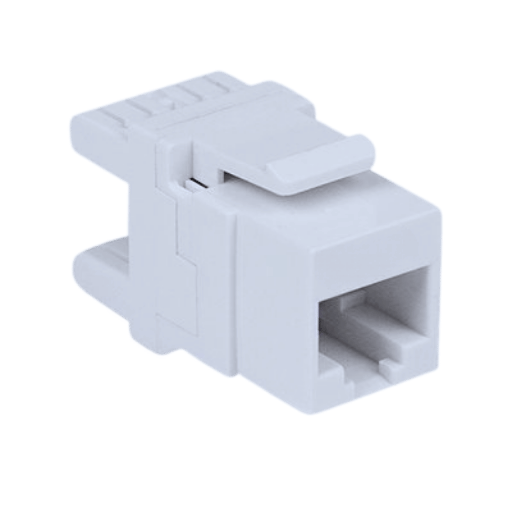

Understanding the Cat6 RJ45 Keystone Jack Design

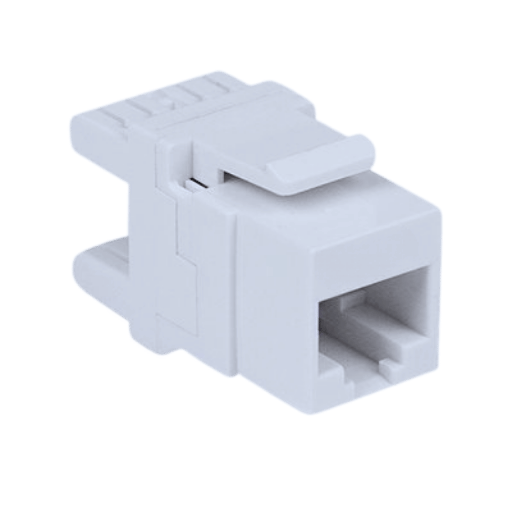

The function of the Cat6 RJ45 keystone jack’s design works on the optimization and accuracy of the connection for high-speed networks. It incorporates an industry-standard RJ45 interface to ensure compatibility with ethernet cables and networking devices. Within the jack, the internal connections are narrow, so it meets Cat6 requirements, can maintain data speeds up to 1 Gbps, and is able to minimize crosstalk. The modular keystone form makes it simple to add the jack into a wall plate or a patch panel, which increases its utility in various network configurations. Such features make certain that the jack is able to work adequately in both residential and professional settings.

Advantages of Using a Cat6 Keystone in Networking

Elevated Network Performance

- With a bandwidth of 250 MHz, Cat6 Keystone jacks facilitate data transfer of up to 1 Gbps. They are best suited for high bandwidth activities such as large file transfer, video streaming, and online gaming.

Reduced Alien Crosstalk

- The design of Cat6 Keystone jacks considerably minimizes alien crosstalk and internal noise, leading to enhanced reliability in the quality of network communication and signal strength, particularly in high EMI environments.

Hybrids Support

- Backward compatibility with previous standards also enables a seamless transition from Cat5 and Cat5e cablings without hindering existing infrastructure. Updates to new standards can be integrated later, ensuring future-proofing.

Versatility in Configuration

- The modular keystone construction allows for easy configuration of wall plates, surface-mount boxes, or patch panels. This varies deployment from a single household to enterprise-level installations, supporting all building networking configurations.

Economical Device Maintenance

- Regular maintenance spends in a business are dramatically reduced through reduced Cat6 Keystone jack replacements along lasting composite construction designed for enduring stress and prolonged use, performance, and optimal expenditure-strategic.

Superior Network Performance

- Collection of these jacks leads to lowered latency and strengthened data access enabling formatted operations in data-heavy environments, thereby, optimizing stable interconnects and higher capabilities.

Future-Proofing

- Selecting Cat6 keystones guarantees their use for upcoming network requirements since they accept newer technology integration and higher bandwidth levels than previous cabling standards.

Standards Compliance

- Cat6 keystone jacks comply with the necessities of TIA/EIA-568 and other industry standards of certifiable level, scope, and performance. This compliance promises trust of quality and connection across numerous networks.

How the Connector Enhances Signal Quality

The construction and performance features of Cat6 keystone jacks are critical in optimizing signal maintenance and enhancement within the network. These connectors are manufactured with meticulous contact shielding to reduce crosstalk and electro-magnetic interference (EMI), and crosstalk mitigation. Significant reduction of crosstalk due to proprietary internal pathways insulation works on both ends: near-end (NEXT) and far-end (FEXT) crosstalk reduction.

Moreover, attenuation of up to 250 MHz allows Cat6 keystones to transmit data up to 10 Gbps (55 meters) with efficiency over short distances, ensuring fidelity (data loss prevention), per required standards. Performance standards are stringent for the connectors, focusing on ideal impedance to signal reflection and transmission speed constancy for optimal signal degradation during transmission.

Moreover, the optimal construction of the connectors ensures longevity protecting against temperature or humidity incurred signal deterioration. Many made of Cat6 withstand the test of time, protecting the transmission performance over time. With all of these relics combined, Cat6 becomes indispensable in the development of dependable, high speed network solutions.

How Does the Keystone Jack Installation Process Work?

Steps to Install a Cat6 RJ45 Jack

Assemble the Required Tools and Materials

- Before you begin, make certain that you have all the required tools and materials. These should include a Cat6 RJ45 keystone jack, a cushioned punch-down tool, a cable stripping tool, and a length of Cat6 Ethernet cable. Also, it’s a good idea to have a cable tester on hand to confirm everything is properly installed after finishing the work.

Strip the Ethernet Cable

- With a cable stripper, meticulously strips the outer insulation of the Cat6 cable for around 2 inches. Try to avoid cutting the internal wires as much as possible. Inside, you will find four pairs of twisted wires—each set will have to be untwisted, straightened, and slightly separated for installation.

Determine the Wiring Standard

- Check the wiring diagram located on the front face of the keystone jack. The most used standards in networking are T568A and T568B. To maintain uniformity throughout your network, adhere to one wiring standard for all connections. T568B is frequently seen in most network installations.

Position the Wires in the Jack

- Following the wiring standard you have selected, carefully place the wires into the appropriate color-coded holes of the keystone jack. Carefully place each wire into the appropriate slot without causing tangling or unseating. Accuracy in this step is very important in order to avoid cross-talk and interference.

Employ the Punch-Down Tool

- With the punch-down tool, the wires are secured into the slots of the keystone jack, and any excess wire is trimmed. A clean and secure connection is established. It is important to apply adequate pressure so that the wires do not come loose.

Slip The Keystone Jack Into The Wall Plate Or Panel

- Having secured the wires, the keystone jack can be snapped into the preset place of the wall plate, patch panel or surface mount box. Ensure that it receives a firm click to indicate that it is secure.

Check The Connection

- A cable tester should be employed to check for the continuity and correctness of the wiring. This step checks faulty connections, reversed pairs, or open circuits. Errors should be settled before the installation is deemed complete.

Carrying out all these steps will allow for the setting up of a network that is reliable and efficient, while ensuring Cat6 data transfer speeds and high signal integrity. With professional-grade Cat6 RJ45 keystone jacks, modern network infrastructures achieve operational efficiency with minimal effort.

Tools Needed for Punch-Down Installation

- Punch-down Tool: Utilized to efficiently and securely terminate wires into the keystone jack.

- Cable Stripper: Used for removing the outer protective layer of the Ethernet cable without causing any harm to the internal wiring.

- Cable Cutter: Assists in the preparation of the cable by providing accurate and precise cuts.

- Keystone Jack Holder or Base (optional): Facilitates the fixing of the keystone jack, thus enhancing its stability.

Common Installation Mistakes to Avoid

Incorrect Wire Pair Termination

- Improper termination of wire pairs is a common mistake made while installing keystone jacks. With Ethernet connections, the T568A or T568B standards need to be followed for the connections to work. Incorrect alignment of pairs can cause signal degradation or lower transmission rates which can greatly hinder the performance of a network.

Failing to Maintain Twisted Pairs

- Untwisting the wire pairs too much during the termination of cables has the potential to lower the quality of the connection due to increased EMI (electromagnetic interference). The recommendation is only to untwist up to a maximum of 0.5 inches while re-ensuring the integrity of the twists to preserve signal quality.

Excessive Cable Length

- Data transmission difficulties can occur due to the exceeding of preset maximum cable lengths for Ethernet standards. For Category 5e and 6 cables, the maximum length is one hundred meters (328 feet). Going past these distances can increase signal attenuation along with reducing network efficiency.

Skipping Cable Testing

- Failing to test cables after installation is an oversight that constitutes an installation error. Testing with a cable ensures that the wires that have been terminated are wired correctly and checks for faults such as shorts or incorrect pinouts.

The Consequences of Strapping Cables Ties Too Tightly

- When pull or strap cable ties too tightly, they risk compressing the cables which can destroy the internal wiring and configure signal performance. In order to avoid damage, it is better to use velcro ties or refrain from fastening cable ties too tightly.

Allowing Stray Voltage Without Proper Grounding

- Neglecting to put appropriate grounding on all parts of the network creates the risk of having them susceptible to electrical surges and EMI. It is important that the network is properly grounded especially to areas with high electrically active components in order to sustain the system healthiness.

These simple steps will help avoid errors that could lead to diminished installation quality, ensuring functionality, reliability, and longevity of the system. Adhering to standards and employing the right tools optimizes efficiency, reduces errors, and ultimately streamlines the installation process.

Why Are Customer Reviews Important When Buying?

Analyzing Customer Reviews for Top-Selling Products

Customer reviews are important to consider when analyzing the best-selling products. Such insights are essential since most customers share their experiences, giving feedback on product usefulness, longevity, and overall customer contentment. Verified reviews emphasize positive or negative patterns, enabling buyers to make better decisions. Oftentimes, positive feedback confirms the good quality of the product or service. However, consistent adverse reviews are a good indicator of persistent issues. Reviews should be viewed in aggregate rather than evaluating singular pieces of feedback to be left with the best understanding of a product while avoiding bias. This method helps gain an unbiased overview that better estimates a product’s fundamental value.

Key Factors Users Consider According to Reviews

Critical explanations during review analysis help users formulate decisions regarding the value and performance of a product. Outlined below are some of the major factors a user identifies during review assessment:

First Impression and Achievement

- A user focuses on the feedback concerning a product’s reliability. Reviews with a focus on long-term performance or wear-and-tear issues are especially convincing.

- Example Data: 68% of users report quality and acheivement as the most important factor when regarding a purchase (Consumer Behavior Insights, 2023).

Price vs. Worth

- Reviews greatly consider a product’s price relative to its offered features and functionality (value). Exorbitant price tags are only acceptable if the product guarantees unmatched quality, exclusive traits, or features.

- Example Data: 52% of buyers state they check reviews about the value for money the advertised features offer (E-commerce Study, 2022).

Intuition and Enjoyment

- Electronics, tools, and software that do not require extensive training are usually rated high. Notable complaints stem from products that are tedious to learn and set up from basic expectations.

- Example Data: 41% of evaluators mention the ease of use as a major factor during evaluation.

Support and Policy Change

- The technical support offered after a sale is as important as actively helping customers troubleshoot issues. These elements heavily impact feedback, especially if not executed correctly, leading to negative reception.

- Example Data: 36% of negative reviews recount customer service problems detailing deep dissatisfaction, which shows how critical customer service is in a purchase decision.

Product Features

- Users tend to have an opinion regarding comments on product features on whether they fulfill their requirements or deliver their promised objectives. Lack of essential or requisite features is one of the major sources of complaints.

- Example Data: In both negative and positive reviews, feature performance is discussed over 48% of the time, demonstrating its importance towards evaluation.

Shipping and Packing

- Online shoppers pay particular attention to the speed of product delivery and the condition in which it arrives. Products that are damaged or improperly packaged often face negative reviews, regardless of their actual quality.

- Example Data: Surveys show that a disproportional amount of sellers, about 33%, cite poor shipping as the reason for negative reviews.

The buyer will improve his useful previosuly of detractor reviews by critically analyzing these comments enabling him to understanding the basic advantages and importance of the product rationally therefore improving their purchase decisions.

What Are the Different Categories of Keystone Jacks?

Comparing Category 6 with Other Ethernet Standards

Category 6 (Cat 6) Ethernet Cables are a new class of Cat 5 and Cat 5e cables, having added features and improvements. Their design allows them to support gigabit Ethernet and greater transfer speeds. Cat 6 cables can manage 10 Gbps of data transfer over short distances (up to 55 meters) and have a higher frequency band of 250 MHz, which is an improvement over 100 MHz in Cat 5e. Therefore, these cables are ideal for environments with data centers and high-bandwidth offices that require fast and stable connections.

While Cat 5e is widely used across offices due to its relative cheapness, Cat 6 is an upgrade that addresses the greater signal-to-noise ratio and crosstalk issues. These attributes make Cat 6 more reliable under difficult conditions. The better performance of Cat 6 can be attributed to tighter pair twists with improved insulation.

Bandwidth for Cat 6a (previously known as only Cat 6) is improved to 500 MHz, with 10 Gbps of data able to be sent over distances of up to 100 meters. These capabilities make Cat 6a favorable for large scale industrial setups and other extensive networking installations.

In contrast, newer standards such as Category 7 (Cat 7) and 8 (Cat 8) serve very specific purposes with even higher frequency and shielding capabilities. Cat 7 has bandwidth of up to 600 MHz and Cat 8 has bandwidth of up to 2000 MHz, with data transfer speeds of 25 to 40 Gbps. These are primarily found in data centers or advanced commercial settings due to their high costs, as they do not serve residential or small business networks well.

In the end, choosing the right Ethernet standard is a balance between the scope of work, network performance, and the budget. For most situations, Cat 6 is optimal because of its versatility and ability to withstand future technological advancements. However, for maximum speed and reliability, cutting edge applications will likely lean towards other advanced categories like Cat 6a or higher.

Understanding the Electrical and Mechanical Contacts

Electrical and mechanical contacts serve to maintain reliable interconnectivity within a system. Contacts are composed of circuits that serve a specific function within a system. Its purpose is to conduct electrical current, and in order to achieve this, a connection point has to be made associated with highly conductive materials such as copper or silver alloys. The phrase “ mechanical contacts “ denotes the level of physically associated mechanical contacts with mate surfaces oriented in such a way that they serve to provide a stable connection.

The performance of electric contacts is influenced by primary factors such as environmental conditions, surface finish, and material composition. Resistive strength, corrosion, and lasting burning qualities create obstructive flow through contact over a monitored period of time. Industrial and residential design tend to integrate these designs in order to lower the possibility of contact failure and boost functionality and make them durable over a long period of time.

How to Achieve Superior Performance with Keystone Jacks?

Ensuring Reliability Through Proper Termination

Keystone jacks function optimally only when properly terminated. Utilize good grade termination tools such as a punch-down tool to lock the wires into place. Follow color legends provided by industry norms T568A or T568B to ensure accuracy. Check the connections to ensure wires are not misaligned or loose which can cause signal degradation. Finally, post termination, refrain from coiling or putting strain on the cables to maintain reliability.

Maximizing Crosstalk Reduction in Networks

To reduce crosstalk in network cables effectively, pay attention to the following practices:

- Employ Shielded Cables: STP provides more shielding and, therefore, more protection against crosstalk and other electromagnetic interferences.

- Ensure Proper Ample Separation: Spacing cables away from power lines as well as other sources of interference reduces overlap of signals.

- Follow Standard Procedures: Using T568A or T568B custom wiring schemes is advised since they provide correct alignment along with mitigating interferences.

- Refrain from Untwisting Wires: Do not over untwist pairs while terminating as it increases the vulnerability of the cable structure and increases risks of crosstalk.

- Cables of Higher Categories: Consider using higher-category cables (e.g. Cat6 or Cat6a) which provide stronger defenses against crosstalk due to advanced design for high frequency use compared to their lower category counterparts.

With all of these measures taken, the efficiency and reliability of the network is preserved as well as its high signal integrity.

Frequently Asked Questions (FAQs)

Q: What is ideal in a network application for a Cat6 RJ45 UTP Keystone Jack?

A: Cat6 RJ45 UTP Keystone Jack has the capability of up to 10 Gigabit Ethernet which means it is compatible with the advancement of technology. It also has standard keystone configuration for easy installation and flexibility.

Q: What effects does the punch-down stand have on the installation?

A: The down stand aids in the installation by securing the keystone jack to the punch-down stand, increasing the ease of wiring, and guaranteeing positive lock with the punch tool.

Q: What is the most important part of these jacks, and why?

A: These terminals are very important because without them there is no reliable connection for the Cat6 RJ45 UTP Keystone Jack. It is known as offering reliable connection with the capacity to ensure the connection is not broken.

Q: Why do you think the diagram is attached to the product packaging on Cat6 RJ45 UTP Keystone Jacks?

A: The attached diagram explains a step by step procedure to easily follow the right color code and connect wires into their designated terminal which helps prevent circuitry problems that misfunction the jack.

Q: In what manner do the strain relief caps help the performance of the keystone jack?

A: Relieving strain caps prevents the cables from making undue tension on the connection, which allows the Cat6 RJ45 UTP Keystone Jack to deliver optimum performance.

Q: Why is it advantageous to purchase a 10-pack Cat6 RJ45 UTP Keystone Jack?

A: Economically, a 10-pack Cat6 RJ45 UTP Keystone Jack has ample value in providing quality connectivity to multiple ports for a larger project without spending excessively.

Q: Loosely speaking, how do these keystone jacks ensure compatibility with 24 AWG wire?

A: The premium design and construction of Cat6 RJ45 UTP Keystone Jacks guarantee reliability with 24 AWG wires which offer a solid connection.

Q: What do you consider to be the most salient fact that you know about UTP keystone jack housing?

A: The housing of the UTP keystone jack provides strong shielding for the internal parts and features the connectional interface aiding in hostile signal interference and thus, excellent signal integrity.

Q: What are the reasons a manufacturer might offer these products individually packaged or in a 50-pack?

A: Offering products in both individually packaged units and bulk 50-pack options allows customers to purchase the quantity suitable for their specific requirements, maximizing flexibility and savings tailored to the scope of their networking project.

Q: What factors should be taken into account when selecting a keystone jack for 10 Gigabit Ethernet usage?

A: Factors that ease the installation and provide a secure connection that meets the required ISO 11801 standards are critical when choosing a keystone jack for 10 Gigabit Ethernet to guarantee exceptional performance.

Reference Sources

Category 6 cable

Ethernet

Modular connector

Post Views: 2,081