Power distribution is the most important in relation to data centers, server farms, and high-density computing environments. In this ecosystem, there is a single essential element that plays a very significant role, known as the C19 power cord. This article will highlight why the C19 power cords are necessary, the technical specifications involved in them, various applications, and guiding principles on how to select an appropriate cord for your needs. It doesn’t matter whether you’re an IT expert, facilities manager, or just someone who wants to learn more about electricity distribution systems; this guide will provide all of the information required so that decisions can be made rightly and things run smoothly with devices’ efficiency guaranteed at the end.

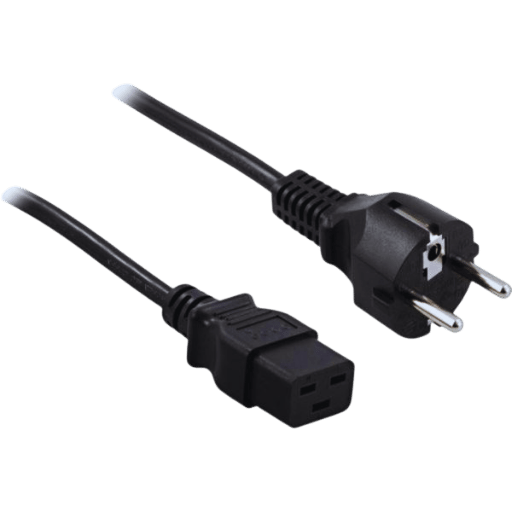

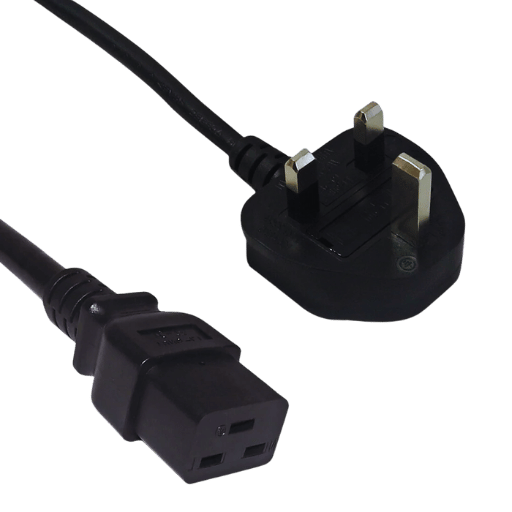

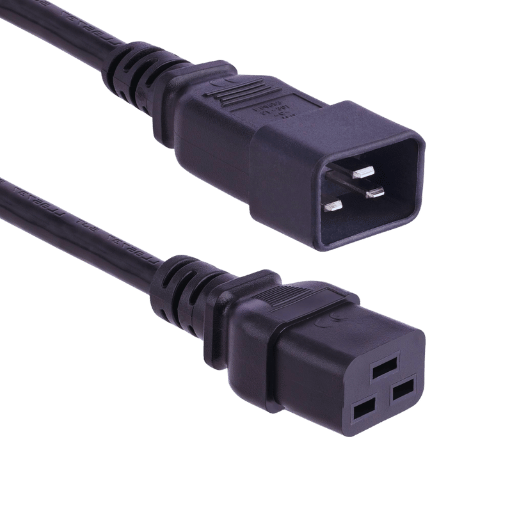

C19 and C20 connectors are types of power connectors that have been agreed upon as standards. These standards are mostly applicable in densely populated computing spaces such as data centers. The C19 connector is the point of connection to equipment that receives power, while the male end, called C20, connects to the power source. Being able to deal with high currents, they support up to 16 amps at 250 volts, hence being ideal for reliable distribution of electricity for mission-critical infrastructures due to their strong nature.

In data centers, it is a must to have C19 power cords so that they can connect high-power equipment like servers, networking switches, and Uninterruptible Power Supplies (UPS). They are designed to be able to handle up to 16 amps at 250 volts, which makes them perfect for powering high-density racks and blade servers that need strong, dependable sources of power. Moreover, these wires are commonly used in power distribution units (PDUs) where they help stabilize the electric current throughout and reduce downtime thus optimizing the entire process within the data center.

The design specifications, current capacity, and typical applications of C19 power cables are different from those of C14 power cables.

Design and Specifications:

Current Capacity:

Typical Applications:

To sum it all up, we can say that while both transmit electrical energy from one point to another, there are factors that make them suitable for different kinds of equipment and power loads. Therefore, knowing about these dissimilarities will help ensure efficiency and reliability during distribution across various environments.

While selecting the correct C19 power cord, one major determinant is the American Wire Gauge (AWG) rating, mainly between 12 AWG and 14 AWG. The number shows how wide or narrow a wire is; low numbers imply that wires are thick.

12 AWG Cables:

14 AWG Cables:

In conclusion, whether one opts for a 12 AWG or a 14 AWG C19 power cord depends on their specific equipment power needs and installation environment requirements.One should go for thicker cables if they require more electricity and want to reduce loss due to resistance while thinner ones would suffice where standard amounts are necessary.

Electrical products must have UL (Underwriters Laboratories) and cUL (Canadian Underwriters Laboratories) listings to become safe. These certificates imply that the item has undergone a thorough check-up and complies with strict safety rules imposed by the American or Canadian government agencies responsible for electrical devices’ quality control. The employment of cables that UL or cUL lists ensures observance of local electric codes; it also lowers the chances of fire outbreaks or electric shocks while giving confidence in reliability and durability at the same time. This feature cannot be ignored within data centers, laboratories, factories, etc., where electricity is widely used, and its safe operation is a top priority.

When choosing power ratings of 250V, 125V, or other values, it is important to choose a power cord whose voltage rating matches the requirements of the equipment being powered.

It guarantees safety and efficiency too. Not enough energy can be supplied by an underpowered cord while excessive energy inefficiencies or even damages may occur due to overrated cables. Always check manufacturer’s instructions for correct voltage rating applicable to your specific application.

To ascertain the conformity of C19 power cords with server power cords as well as network equipment, it is crucial to make certain that the voltage and current prerequisites of the apparatus match those of the electric cables. High-power gadgets such as servers, data centers, and networking hardware, which require strong performance, usually work well with C19 power cords. These are fit for environments with high energy demands because they can handle large currents. Always ensure that you crosscheck the specifications given by both the power cord and equipment so that they are compatible and safe to operate together.

C20 to C19 adapters are connectors which can connect a C20 inlet to a C19 outlet. They are commonly used in high-power settings like data centers or server rooms where equipment may have different plug types. These devices make sure that a piece of equipment with a C19 power cord can be plugged into a C20 inlet so that power is distributed efficiently and safely.

Alternatively, 5-15P to C19 adapters allow for the use of standard 5-15P outlets found in homes and offices with C19 equipment. Such adapters serve well when high-power devices need to be integrated into environments dominated by 5-15P outlets, thus enhancing power management flexibility.

In short: Yes, it is possible to use C19 power cords with different devices using higher power needs addressed through the application of C20 to C19 adopters while more common residential or office setups can take advantage of 5-15P to C19 adapter. Always ensure compatibility by checking voltage/current ratings on both sides (equipment & adapter).

Designed for high-current applications, the C19 power cord is ideal for distributing power from a Power Distribution Unit (PDU) in data centers and other demanding settings. Top Google results indicate that C19 power cords are needed to connect PDUs with high-capacity equipment such as servers or networking devices. These cords generally support up to 20 Amps so that even heavy loads receive stable, reliable power.

To integrate PDUs with C19 power cords, one must consider connector compatibility as well as electrical specifications. Most PDUs equipped with C19 outlets are designed for managing high-power appliances; therefore using an appropriate power cord is important in order not to expose oneself to potential electric hazards. Moreover, the overall performance of these systems may be affected by factors such as the length and quality of a c19 power cable, where better materials offer increased durability alongside improved efficiency.

Consequently, when considering whether or not you should use c19 Power Distribution Unit cords for delivering electricity into your PDU(s), make sure both connector types match device requirements while also ensuring that they can handle required current/voltage levels — doing this will help establish safety throughout the infrastructure while also promoting its effectiveness.

C19 power cords of the heavy-duty variety can be purchased; they are different from regular ones because they are built better and have more amperage. Heavy-duty cords are made to withstand tougher conditions and usually support 20 Amps, which is appropriate for high-performance settings. Conversely, standard power cables manage less electrical current and may wear out faster if used heavily or frequently. Therefore when selecting between these two types of power cord, consider the electrical demand as well as durability needs for your particular application in order that safety precautions are met while achieving maximum efficiency.

Heavy-duty power cords can be identified by their Service Junior Thermoplastic (SJT) jackets, which offer extra protection against physical abuse, moisture, and weathering. When choosing an SJT jacket for a heavy-duty C19 power cord, you should check whether the cord is labeled as compliant with SJT standards and also verify how thick and pliable it is. A strong SJT jacket needs to be tough but still flexible so that it can withstand being bent or twisted around in demanding environments. Having such sturdy features on your C19 power cords will ensure that the power supply system will serve you faithfully for a long time.

It is important to think about the electricity and physical limitations of your setup when selecting extension cords and angle power cords. Extension cords are used to increase the distance between a device and an electrical outlet. This will help you put machines in places where there are no outlets. When using extension cables, make sure they can handle the current that runs through them without burning out or getting too hot; if not, then it might cause accidents such as fires.

Heavy-duty extension cords like heavy-duty C19 cords can carry loads up to 20 Amps or higher.

On the contrary, angle power cords are made for space-saving and maneuvering cables within tight or intricate areas. These have connectors with right angles (usually 90 degrees), which allow neater installations without bending the wire too much. With this type of design, there will be reduced strain on connectors, plus it looks tidy, especially in data centers or racks.

Key Features:

Selecting suitable extension cords alongside those with angled plugs could greatly improve safety standards as well as functionality levels within any given power delivery system henceforth realizing top performance even under extreme workloads.

For C19 power cords, NEMA (National Electrical Manufacturers Association) and IEC (International Electrotechnical Commission) standards are very important as they ensure safety and compliance. Mainly dealing with electrical infrastructure and components used in North America, NEMA standards describe how power cords should be designed or what their performance should look like, including plugs and connectors. On the other hand, IEC standards are recognized worldwide to enforce consistency among electrical items sold internationally; it also ensures that such gadgets work together in any given market. Such observance guarantees that products satisfy strict safety regulations while still meeting operational efficiency demands, enabling safe distribution of electric power locally and globally.

To prevent accidents caused by C19 power cords in industrial settings and data centers, the following measures should be observed:

With these simple rules, developers can design secure energy distribution systems for data centers and factories.

Cords with power in relation to C19 need to be tested and certified for safety reasons as well as for their performance in high-demand areas. The following are some of the usual processes:

Through strict adherence to these measures of testing and certifying; manufacturers make sure C19 power cords are dependable, secure and appropriate for use in harsh conditions.

A: A C20 to C19 power cord is an AC power cord specifically designed for heavy-duty applications. The plug connects to a power source, while the connector is meant for powering equipment that needs high energy, such as servers and data center equipment.

A: These cords are typically found on Power Distribution Units (PDUs), servers, and other data center equipment. They can also be used with UPS (uninterrupted power supply) systems to ensure reliable power connectivity.

A: Most C20 – C19 cords are rated at 250V for power and support up to 20 Amps (20A), which makes them suitable for high-power applications.

A: Yes, many of these cables come with UL & CUL listings, which guarantee safety standards compliance during their manufacturing process, making them best suited for critical applications within North American markets.

A. Different lengths and wire gauges are available. For example, an 18 AWG offers flexibility and is lighter, while heavier-duty options like 16A can support more demanding loads.

A. Most manufacturers provide certification information, including RoHS & REACH compliance within their product specifications; therefore, always check these details when selecting any type of PDU cable so that environmental and safety standards may be met accordingly.

A: They are compatible with PDUs and equipment that comply with North American power standards. However, ensure the equipment and cord ratings match the power source requirements.

A: It is a robust connector designed for heavy-duty applications where high-performance equipment such as servers needs to be supplied with optimal levels of electricity continuously without any interruptions. Thus, it ensures reliable energy transfer in environments requiring consistent performance through uninterrupted power supplies (UPS).

A: Factors to consider include cord length, wire gauge, voltage rating, current rating, and certifications like UL and CUL listing, among others. This ensures that you get what best matches your equipment’s needs in terms of safety precautions and power consumption efficiency.