With the swift advancement of technology, it is now apparent that an efficient power remedy should be selected to enhance the performance of an electronic device. Regarding electrical interfaces between components and power sources, the C13 to C14 power cord acts as a very important auxiliary. In this guide, the author will outline almost all the pertinent details about C13 to C14 power cords, including their specifications, areas of use, and all that needs to be remembered when selecting the best cord for your specific needs. This guide entails information that will be useful whether one is a professional IT practitioner, a technician, or an ordinary person wishing to understand how electrical interfacing is done.

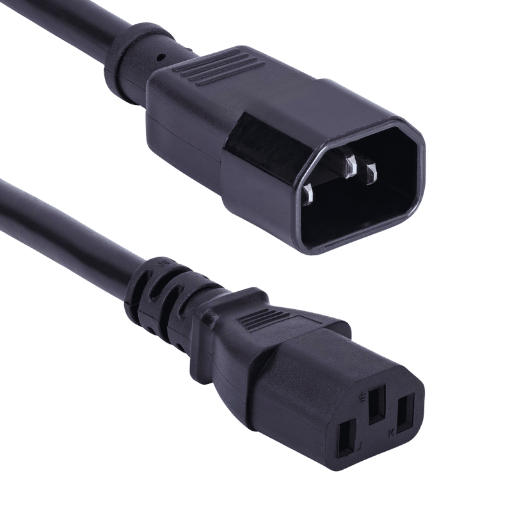

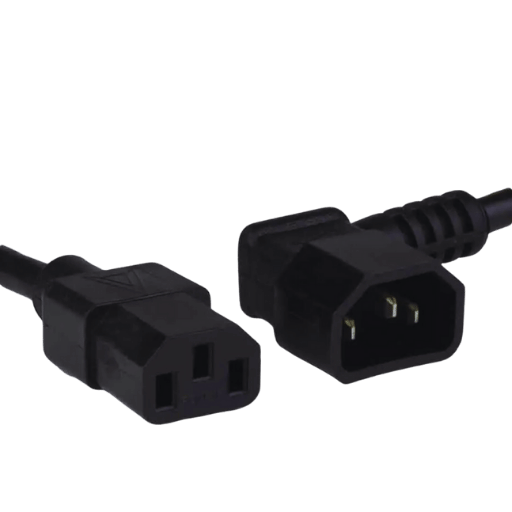

The connectors C13 and C14 are universal power sockets produced by the International Electrotechnical Commission (IEC). The C13 inlet, also known as the C13 socket, is used on power supplies, portable power strips, and computer equipment and is rated for cables up to 10A at 250V. The C14 receptacle, on the other hand, is generally the female part that has to be inserted in the C13 intended to provide main connectivity. These types of power connectors allow interconnectivity between actresses working on the production of different products within a shorter time period. Also, these connectors do not only apply to the IT and telecommunication industry but also to consumer electronics, helping withstand and be safe in standardized electronics.

IEC 60320 and other relevant standards are very important in terms of safety, compatibility, and reliability of the power cord sets, including C13 to C14 climate. These normative documents also determine the structural and performance parameters of the connectors, which makes it easier to construct devices compatible with various manufacturers. IEC 60320 also helps to show that the power cords are capable of operating under the predetermined ratings of current and voltage, hence avoiding electrical accidents. The guidelines help avoid a heterogeneous set of practices with respect to electrical connectivity around the globe and, as a result, promote the integration of devices into a variety of environments, be it data centers or home offices. Adherence to and following these regulations helps manufacturers explain the services offered to their users, ensuring the quality and safety of the given connection means.

C13 to C14 power cords are in great demand across different sectors and for various uses because of the dependable connection and generic design. Most commonly, it is used in the data center where the power couplers are used to join servers, switches, and other networking devices to a power socket or PDU (power distribution unit) for effective management and distribution of power. Such cables are also utilized in consumer force linkage between desktop computers, monitors, and printers for their proper use as well as ensuring safety. They also come in C13 to C14 power cords that are used for laboratory and medical equipment, which require electrical connections to be very accurate and reliable. Their flexibility and compliance with IEC standards make it possible for them to be used for many functions in business and at home.

The C13 to C14 power cords are rated at 250 volts. This specification is particularly important for a device that needs to work with many different electrical devices and appliances. Such cords can also work in many settings where there are practical power needs because they can cope with such a voltage limit.

This 250V rating is common in some areas, consistent with the IEC standard, which includes the C13 connectors for that voltage and below applications. It is also important to make sure the devices to be hooked onto the power cord do not surpass this voltage level, which, if done carelessly, could result in overheating or damage and failure of the electric parts intended for that application area.

This voltage rating in practical sense supports wide applications including personal computing devices and machine tools including heavy industrial machinery. For example, the average voltage required for most desktop towers which are powered on is approximately 100-300watts; hence, there is sufficient justification to buy a 250V power cord since multiple devices may be in operation at the same time without endangering performance and safety.

C13 to C14 power cords are available with current ratings of 10 amperes (A) and 15 amperes (A). For the intended use, the selection of the current rating is important in terms of the performance and safety of the electrical apparatus. 10a rated cord is appropriate for lower power-consuming devices, hence personal computers and their peripherals. The 15 option is, however, utilized in more demanding power consumption apparatuses such as servers and heavier electricals that require more power. In connecting the devices to the power cords, the total load of the device connected should be in line with the power rating of the power cord in order to prevent heating up or failing, which can put the safety of the devices and the user at risk.

A wire gauge is critical when picking out a power cord since it affects how well the power cord performs and the safety level it provides. The American Wire Gauge, which is a system of measuring the gauge of wires, clearly indicates that the larger the number, the smaller the wire diameter. In cases where a stronger connection is required, 14AWG wire is preferred because the wire accommodates large current ratings very well with very little volt drop, making it favorable for heavy-duty machines and appliances. However, 18AWG wire will only be sufficient for devices with less current flow, such as personal computers or small peripherals. It becomes evident that the wire gauge must have a relation with the application so as to minimize chances of overwiring as well as maximize performance. In addition, this choice of wire gauge aids in the rest of the concept, such as preferences that help in preventing electrical accidents as per the electrical codes.

There are many factors which one has to consider while choosing one appropriate C13 to C14 power cord instead of just fulfilling the need of the equipment.

Though these factors are critically examined, users are able to assured that their C13 to C14 power cords would not only fit their devices but also work as expected without posing danger under operational conditions.

One of the crucial certifications for electric items such as power cords is the Underwriters Laboratories or the UL certifying body. It conveys risk that the product is safe to the consumers since they have been subjected to tests to eliminate hazards such as electrical fires, shocks, and damage to equipment. Any product that has the UL mark gives the users a sense of safety and performance of the item as it adheres to the industry’s standards and protocols. In addition, utilizing UL-certified power cords will aid businesses in fulfilling legal and insurance obligations, thus decreasing risk exposure and increasing overall operational safety.

The SJT rating is typical of a thermoplastic elastomer cable, which is meant to suggest that it is suitable for different environments and applications. “S” is for “Service” meaning that the cord is to be used in an area\ where a degree of flexing and ruggedization is necessary. The cord ‘J’ states that such a cable has insulated conductors that satisfy certain specifications, whereas ‘T’ portrays the cable as having a weather-resistant thermoplastic coating. Such SJT cords are designed for use in a variety of situations, including residential, commercial, and industrial use, as they are highly tolerant to abrasion and moisture. In this regard, SJT cables can be used as power cords for tools, appliances, and other equipment that operate under various conditions where bending and twisting are more or less the standard.

The uninterrupted supply of electricity, especially in data centers, is crucial, as it aids in prevention and containment of downtimes. In such a setup, the C13 to C14 power cord offers a very useful link between the server racks and the power supply units. It is also designed to help interconnect various devices in order to achieve effective power management. Further, this type of arrangement helps in load balancing so that there is no risk of overheating or electrical failure. Such power cords built in on stipulations of this nature greatly improve the performance of the data center thus eliminating any possibility of downtime in the critical hardware.

Power Distribution Units (PDUs) are required when it comes to power management and power distribution within the hard structure of data centers. Their use with power cords, especially C13 and C14 types, is very important for helping the PDU operate effectively and enhance safety. Power cords with C13 outlets are also commonly found in PDUs as they have multiple outlets used to plug in a lot of computing and network devices, which facilitates power management.

There are some considerations that should be taken into account when searching for cords that will be used with the PDUs.

Power system to the data centers can appropriately be guaranteed and be made safe for the operations within the data center by understanding these compatibility parameters.

With the reliable maintenance of power cables, the downtimes in data centers and server rooms can be reduced to the minimum. As per technical data available on various relevant sites, these are some of the most popular and efficient factors related to power cables and the reduction of interruptions.

By moving management concerns of outages and importance of effective maintenance of power cables, most organizations can derive operational efficiencies as well as power performance.

Loose connectors may cause considerable amount of power delivery problems within a system. Findings in previous studies include the following types of indications that are commonly seen with defective C13 to C14 connectors:

Organizations must find ways of spotting these signs in good time so as to take remedial action before system stability is lost.

C13 to C14 power cord problems with voltages are primarily of two types: under-voltage, which causes excessive voltage drops, or over-voltage, which appears as spikes. Both can be detrimental to the performance of related equipment. To resolve these issues, perform the steps as follows:

Analyzing these causes in a step by step basis will assist the organization in all the procedures which will in turn allow them to correct voltage problems so as to supply power to systems reliably and increase their effective operation.

Failure to look after power cords properly and storing them properly results in almost complete loss of their utility. Consider best practices on the following:

The above maintenance and storage procedures will contribute toward promoting the proper and efficient handling of power cords in the organizations and particularly reducing the hazards associated with electrical connectivity.

These suppliers offered good product standards and also customer service support within the power connectivity market.

When purchasing C13 to C14 power cords there is always a choice to make between online and local retail shops. One needs to travel, which is time-consuming. In such a case, there are advantages to doing online shopping. For one, there is an easy comparison of prices and product specifications without thinking of where to go. Most online retailers carry many more items, including some very niche items that local stores may carry. Also the reviews by other customers are helpful.

On the other hand, local retailers provide the advantage of instant gratification in that the customers are able to have the items delivered to them immediately. They also offer the chance to touch the item before buying it, which is necessary for a good number of people who need to know how it feels like before buying. The decision, in the end, should fit each individual’s requirements as far as how fast such items are needed, how many of the items are needed, or how much one prefers physical perception of the goods rather than virtual.

To get good evaluation scores concerning the type of C13 to C14 power cords offered, there are several important aspects that need to be highlighted:

In short, to make you understand better the reason as to why certain C13 to C14 power cords would be ideal for you, you have to focus on the above aspects.

A: A cord having a C13 connector on one end and a C14 connector at the other end is a type of an AC power cord. This cord is mostly used to connect computer equipment to the power supply. These cords are cost-effective and helpful in the provision of additional power connection in offices and data centers.

A: The Chassis cord power is usually rated at 10 amps for this C13 to C14 power cord connection. Always try to check the rating of the specific cord you are using, in order to ascertain that you are within the range allowed by your equipment.

A: A C13 power cord is designed for use with a C14 inlet. C14 power cords are used to connect power to devices like computers & monitors.

A: An IEC 60320 C14 to C13 power cable typically has specifications including a voltage rating of up to 250V and an amp rating of up to 10 amps. These cables are built to conform to the globally accepted standards for power connections that are safe and dependable.

A: IEC320 C14 has a male type connector which is the commonly seen ingoing connector on power distribution units, whereas IEC320 C13 has a female type connector who is normally an outgoing connection on power cords that go into electronics. Together they make a standard arrangement on plug and socket for delivery of AC power.

A: IEC320 C14 to IEC320 C13 power cords are mostly utilized within data centers, server rooms, and with computer power supply units. They are appropriate for use to connect servers, networking hardware, IT devices and other appliances to discrete power distribution equipment.

A: In 10 amp power C13 to C14 power cables, a correct power rating for the equipment is observed, overloading the cord does not occur and the cord is examined for wear and tear. Adhering to proper cable management practices can also minimize damage, and promote the achievement of safety measures.

A: To know if the C13 10A 250V power cord will work for your equipment, check the power specifications of your devices. Cross examine that the voltage and amp rating of the power cord is equal or greater than that of the equipment.

A: The C13 to C14 power adapter is mainly meant for the interconnection of C13 and C14 plugs and inlets. When converting other plug types, be sure to employ the correct adapter for the plug and inlet configuration of the devices.

A: Good quality certified C14 to C13 power cords can be obtained from various electronic shops, e-commerce websites, and from some manufacturers directly. If you need more assistance, do not hesitate to reach out to us for suggestions for trustworthy places.