Choosing the appropriate extension cord for your project is vital for maintaining safety and efficiency. A 14 gauge extension cord is both durable and has high capacity, which makes it a preferred choice for many applications. It is, however, important to understand that not all 14 gauge cords are identical and that their details must be understood prior to making a purchase. This comprehensive guide will make certain you are informed on everything, including power capacity, cord length, insulation, and environmental conditions so that you are able to choose the optimal extension cord to fit your criteria.

An extension cord of 14 gauges is specially created to cope with a dainty range of power loads. “14 gauge” speaks of the moderate thickness of the wire encased in the cord. The lower the gauge, the thicker the wire; thus, more current can be carried. A cord of 14 gauges can carry a maximum of 15 amps, which is moderate for heavy-duty tools, appliances, and gadgets. It is a perfect choice for tools in homes or light commercial use, given the restrictions in length and the power from the devices that are connected.

The safety and efficiency of electrical circuits depend on numerous factors, one of them being the wire gauge. The wire’s thickness, shown by its gauge number, impacts its capacity to carry electrical current without overheating. Increased wire gauge signifies lower numbers, meaning the wires are considerably thicker and, therefore, capable of handling more current. For instance, 12 gauge wire is acceptable for circuits needing amperage of up to 20 amps, with 14 gauge wires supporting circuits with 15 amps. Safely operating and effectively minimizing the risks of voltage drop or overheating involves knowing the right selection and understanding the correct wire gauge. Remember to always check the relevant standards and regulations when selecting wire gauges for certain uses.

Acceptable Current Flow

Diminished Voltage Drops

Reduced Risk Of Injury

Easy to Carry and Install

Electrical Compliance and Standards

Budget-Friendly Approach

All in all, a 14 AWG cord is ideal for ensuring efficiency, safety, and value across many applications. However, to get the best performance from the cord, make sure it is used within its stipulated ratings and guidelines.

Choosing the right electrical cord involves more than just matching its intended purpose. It involves the understanding of gauges and their differences. The gauge number directly indicates how thick or thin the wire is; lower numbers have thicker wires, suited to handle higher currents, while higher numbers have relatively thinner wires which are more suited for lighter loads.

14 AWG vs. 12 AWG

Household tools and common appliances require low power loads, making 14 AWG cords their lightweight and affordable choice. They have a moderate power demand, typically supporting up to 15 amps. However, 12 AWG cords allow for high power demand, such as heavy-duty tools and large appliances, allowing them to fully utilize the 20 amps they can handle. Also, 12 AWG has lower resistance, which makes it far more useful for long distances. It is the ideal choice wherever power delivery is consistent or long-distance cords are used.

14 AWG vs 16 AWG

Unlike the 14 AWG cords, 16 AWG cords are thinner, which allows them to support up to 13 amps. As a result, 16 AWG cords are more suitable for light-duty jobs such as powering lamps, phone chargers, and some small household electronics. However, they can be unsuitable for some appliances and tools that have a higher current draw due to thinner cords generating more resistance and, thus, heat. In this regard, 14 AWG cords are more excellent and flexible for moderate tasks since they are safer to use in devices above the 13 amp range, given their lower weight-to-power ratio.

Voltage Drop and Length Considerations

In terms of performance, the length of the cord has a huge role. For instance, 14 AWG and 16 AWG cords have much higher voltage drops than 12 AWG cords when used at longer distances. Aside from device performance, voltage drop can also pose a danger by burning out devices due to overheating. For distances more than 50 feet, a 12 AWG is better for constant performance as well as safety, while 14 AWG might be enough for shorter distances.

Practical Application Supervision

The type of wire used must be aligned with the specifications of the electrical equipment in question, along with the intended purpose of the cord. For heavy-duty or commercial-grade leading applications, a cord that is 12 AWG is usually the most suitable selection. For typical household items and small outdoor devices, a 14 AWG cord provides a good mix of economy and functionality. Finally, low-power devices using 16 AWG cords should not be used in conjunction with tools or appliances that need high current draws.

Wire Gauge (Thickness)

Length and Voltage Drop

Durable Outer Jacket

Weather Resistance

Safety Certifications

Plug Design and Features

Flexibility and Ease of Use

For safe and effective use throughout numerous residential and industrial settings, remember to combine operation specific needs with other essential features when looking for a heavy-duty 14 AWG extension cord.

The most important factors on any power extension cord are its amperage, voltage, and wattage ratings. These numbers point out the maximum amount of electricity the cord can carry without damage. Always confirm that the power requirements for the devices won’t exceed the limits of the cord, as that can lead to overheating and other dangerous situations. Always look for safety marks like UL (Underwriters Laboratories) or ETL (Electrical Testing Laboratories) as these institutions testify that a set of minimum standards have been adhered to. If planning to use the cord outside, check for a “W” marking, which confirms that the cord is weatherproof.

Indoor extension cables are not insulated as deeply and are meant for protected areas; like the outdoors, these wires are also suited for small appliances around the home. The “W” marking is what distinguishes outdoor extension cords from indoor ones, as these wires can endure moisture, extreme weather, and UV rays and are better insulated. Always take into consideration your equipment’s power demand alongside location and environmental factors when choosing between the two. To ensure your safety, always remember that outdoor weather is something indoor cords are not made to endure.

Always bear in mind that electrical equipment, such as a power tool, has a specific operational parameter that must not be exceeded. Exceeding it will cause overheating or a drop in the voltage supplied. Therefore, under no circumstance should an extension cord be used on a power tool that requires more than what the cord can support. For example, a 14-gauge extension cord is acceptable for power tools that draw about 15 amps, particularly over short distances. However, over long distances, the amount of resistance increases, which decreases voltage.

A 14-gauge cord is suitable for distances up to 50 feet, but longer extensions will likely require a 12-gauge cord instead. Tools like drills, circular saws and sanders are perfectly suited power tools for use with a 14 cord over medium distances, but large equipment like miter or air compressors may require utilization of heavy gauge cords such 12, or 10 gauges depending on amperage drawn.

The owner’s manual is the best source to determine the specific power draw of the device and the gauge of the cord that needs to be used. Using the wrong gauge leads to poor tool performance, overheating of the cord, and poses safety risks. It is always safe to use cords authorized by UL and CSA, as they will ensure safety compliance and optimal performance of the device.

The tools that need to be plugged into an electric supply determine the extender compatibility based on the amperage and wattage it uses. Amperage is defined as the required electric current needed by the tool, while the wattage is the power consumed as a result of voltage and current drawing, meaning it is the product of volts and amps. In the United States, the majority of household circuits provide 120 volts. In that case, a tool that draws 10 amps will use around 1200 watts (120 x 10 = 1200) because 120 volts multiplied by ten amps is equal to one thousand two hundred volts.

Knowing the amperage is useful for estimating the electrical load a device will consume and how it would utilize the existing system or an extension cord. For instance, smaller devices such as electric drills and orbital sanders usually take in between three to eight amps. Large devices like table saws and air compressors require even more, for example, anywhere between ten to fifteen amps. Heavy duty equipment would need ever more, making dedicated circuits vital for safe operation.

It is equally important to know the input voltage and the maximum amperage rating to determine the wattage consumption. When considering international settings where voltage standards are different, such as outlets in Europe that provide 230V, the computed wattage becomes distinct. To avoid tripped breakers or any overheating that could lead to potential fires, electric cords should be rated or guaranteed to guarantee protection by not allowing the computed wattage to exceed the extension cord.

The surges from starting the electric motor will need some attention. During the turn on cycle, most power tools generate a very high starting current which is way higher than the running current. Hence, there is need to choose short-term peak loads in industrial settings and cords of appropriate gauge size.

Amperage and wattage, when properly understood, allows professionals to maximize equipment efficiency, follow proper electrical safety policies, and extend the lifespan of their tools. To achieve the most efficient and safest operation, ensure these particular details are checked directly off the tool nameplate, or from the manual.

Now with a 50-foot extension cord that utilizes a 14 AWG wire, tools and equipment drawing current up to 13 Amperes are acceptable. With lower powered tools or equipment that only require less than 10 Amperes, this distance ensures adequate performance with minimal voltage drop that is effortless.

Though, with a 10 foot extension cord with 14 AWG, the shorter length allows the cord to handle similar amperage with more efficiency due to less chance of power loss. This makes it perfect for high-draw tools that are located near a power source. Always confirm the cord’s amperage rating to ensure that it matches the tools requirements for receipt and effective utilization.

Similar to how the gauge and length of an extension cord affect its efficiency for power delivery, so does its length for voltage drop in AC power. The greater the resistance, the longer the power cords are, which leads to a greater drop of voltage and lower power capacitance. When it comes to 14 AWG cords, the length and the power need for tools ratio are important. Safety is ensured when using a longer cord because it minimizes resistance as performance improves. On the other hand, longer cords should be limited to low-power use cases to avoid dropping too much voltage. Always check the cord’s gauge and length with the load needs to guarantee efficient power delivery.

Assessing the power needs of the appliance in question and cross-examining them with the cord specifications is crucial while using a heavy-duty 14 AWG extension cord. Most household appliances such as microwaves, refrigerators, and air conditioning unit appliances utilize a hefty amount of power. A14 AWG cord tackles almost 15 amps at 120 volts maximum power capacity, routing a whopping 1,800-watt power. However, ropes providing higher power than that, leading to overheating and electrical threats, along with damaging equipment should not be used.

The length of the cord also needs to be considered. With longer cords, there is increased resistance, which encloses greater amounts of voltage drops, leading to a decrease in appliance efficiency. For example, with a refrigerator, if the fridge is plugged into a cord that is further than what is required, there is a risk of insufficient power delivery, which can lead to motor damage. To counter these risks, a short cord length is recommended, and the coiling should also be avoided as it leads to increased heat.

Moreover, always check that the cord’s insulation and general condition remain integrated, especially when used in moist or abrasive surroundings. Defective cords can jeopardize electrical safety and increase the possibility of shorts. Following these suggestions can help prevent both the appliances and the houses from sustaining electrical damage.

The certifications from UL (Underwriters Laboratories) and TAA (Trade Agreements Act) are fundamental to standard compliance and product specifications. For instance, UL certification guarantees that a given product is safe as it has been thoroughly tested and is free from electrical and fire hazards, among industry standards. Businesses and consumers have confidence in the product as its reliability and safety is guaranteed.

On the contrary, TAA compliance certifies that a product’s country of manufacture is eligible under the Trade Agreements Act. For government purchasing, this certification is supremely important as it guarantees compliance with fair trade practices and other stipulated policies.

Individually, they certify the absence of danger, as well as the quality of the product, and that it fulfills legal requirements. These factors are decisive when it comes to evaluating electrical and electronic equipment. And, when considered together, they act as comprehensive checkpoints for product control.

A: A 14 AWG extension cord means that the power cord has a wire gauge of 14, which is able to handle up to 15 amps of current. It is pertinent because it carries current safe for devices with a current rating of up to 15 amps. It also allows safe remote powering of appliances through sockets and is especially useful for bulkier tasks.

A: A 14 AWG extension cord is generally regarded effective for lengths of up to 50 feet. Beyond this range, devices that are connected may not perform due to possible voltage drop. Cords that are longer than that should consider using a heavier gauge cord, or multiple cords that are shorter.

A: Indoor extension cords are designed for use in handles and offices spaces while outdoor extension cords, like a black outdoor extension cords, are manufactured with better materials that bear the effects of weather. Outdoor cords often come with extra layers of insulation and are tagged for outdoor use.

A: In regards to a 14 AWG extension cord and a power strip, yes, a power strip can with one use of a 14 AWG extension atter, you should keep in mind that the total amperage of all devices connected to the power strip should not exceed 15 amps. Some power strips have an integrated extension cord with multiple points of electricity which can replace plugs for power strips.

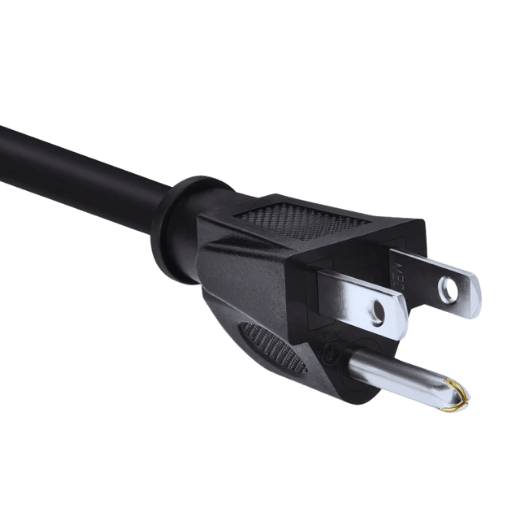

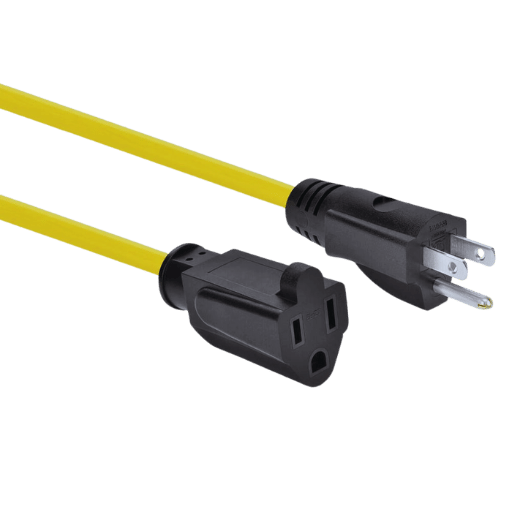

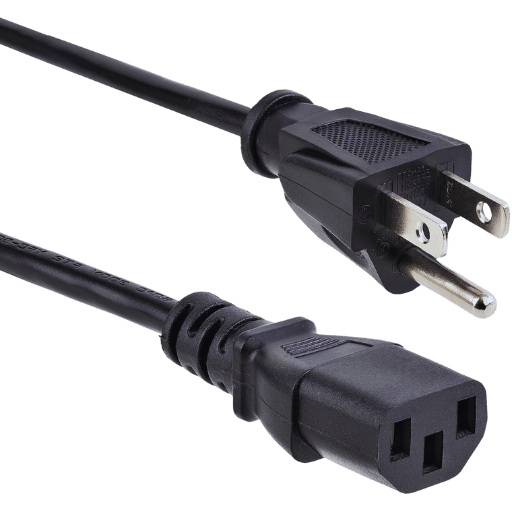

A: NEMA 5-15P to NEMA 5-15R is a nomenclature that describes a type of plug used in cables with extensions. The 5-15P is the 3 way prong attached to the power outlet and the 5-15R is the female socket or receptacle where all the devices are plugged into. This should work for any 125V or 15 A power connection circuits in a home.

A: Yes, flat plug extension cords have a few advantages. They have a low profile and less bulk compared to the traditional design, which reduces the strain on the outlet and allows furniture to be placed closer. They can also be snapped on or off at the base without damaging the extension, which can prevent the cords from getting bent or snapped.

A: For appliances or power tools with a heavier load, such as a vacuum, select a 14 AWG extension cord. If there are other devices like lamps or other small electronics, a 16 AWG extension cord would suffice. For heavy-duty applications, always opt for the lower gauge 14 AWG cord to ensure safe power transmission.

A: Always ensure that the cords are UL-certified or ETL-listed to ensure they are safe for use. Low-voltage insulated wires with proper safes should be considered for outdoor use. Some cords feature built-in circuit breakers or surge protectors. It is part of the user checklist, so always verify the user’s intended use and amperage requirements.

1. Maker and Application of Internet of Things in Intelligent Security By Example of Power Extension Cord

2. FIXING STRUCTURE OF AN EXTENSION CORD FOR ARTIFICIAL CHRISTMAS TREE

4. Power cord