Fiber optic spools are central to the modern telecommunications and data transfer industry as they enhance the deployment and management of optical fibers with unprecedented ease and accuracy. From enormous data centers to fiber-to-the-home (FTTH) applications, these spools guarantee proper handling of fiber optic cabling, thus preventing signal degradation and preserving transmission quality. This article highlights the essential functions and main benefits of fiber optic spool solutions and discusses the ramifications of such devices on effortless interconnectivity across various sectors. If organizations grasp their significance and appropriate usage, they can enhance their network performance and address multiple operational problems.

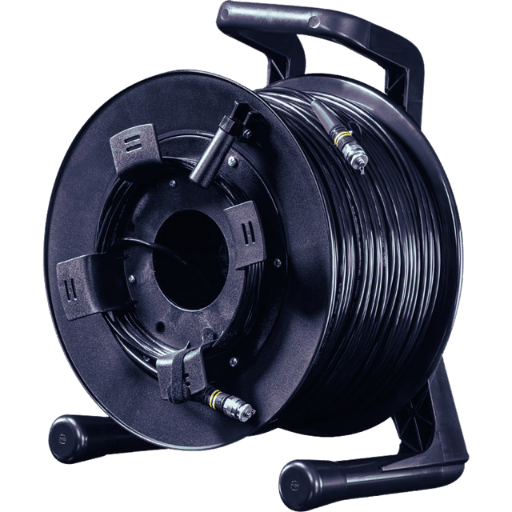

A fiber optic spool is a device shaped like a cylinder used to store, manage, and deploy fiber optic cables properly. Spools are intended to prevent the tangling, damage, and excessive bending of the wires, which may lower the quality of the transmitted signal. Fiber optic spools are widely used in data centers, telecommunications, and networking installations for proper cable management and optimal signal transmission. Spools are essential for the orderly and secure storage of cables, thus ensuring rapid data transfer.

Fiber spools are crafted to optimize the storage and management of fiber optic cables during installation and operation. They also reduce excessive bending and signal loss during data transmission. In most cases, the surfaces of fiber spools are smooth and curved, ensuring the cables are guided well while minimizing force. Their purpose is crucial in data centers and telecommunications systems, where cable management precision impacts network performance and fiber length.

These parts are critical for the effective and proper handling of cables, a factor considered paramount for system reliability.

While choosing a fiber optic spool, it is prudent to assess the project scope so the cable length and diameter are just right. Regarding cable length, ensure the spool can hold the complete length of the fiber optic cable without twisting or putting it under undue stress. In the case of the diameter, confirm that the spool meets the size requirement of the cable so that putting it in does not require much flexing that can harm the fibers or distort the signal quality. Check the manufacturer’s recommendations regarding the specific spool and cable type to ensure the construction criteria comply.

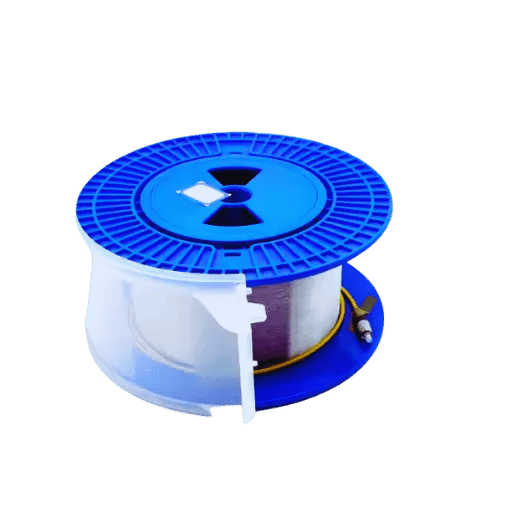

Just as in other areas of production, there are armored bulk fiber spools and compact fiber spools. Each serves distinct purposes based on application requirements and environmental conditions. Armored bulk fiber spools allow for better protection, enhancing their durability and making them perfect for extreme settings with many physical or external dangers. Conversely, compact fiber spools are optimized for storage and movement, making them lightweight and easy to handle during setups in limited spaces. Which one to choose depends on the use case. Compact spools are easier to move but lack a lot of the robustness of their armored counterparts.

The specification sheet emphasizes essential details when choosing the correct fiber spools. For armored spools, primary factors include tensile strength, impact resistance, and operational temperature. These physical restrictions allow for usage in aggressive environments. Compact spools, however, are assessed through their weight, storage volume, and ease of deployment, which suits more portable applications. Both comply with international standards, guaranteeing reliability and performance for these conditions.

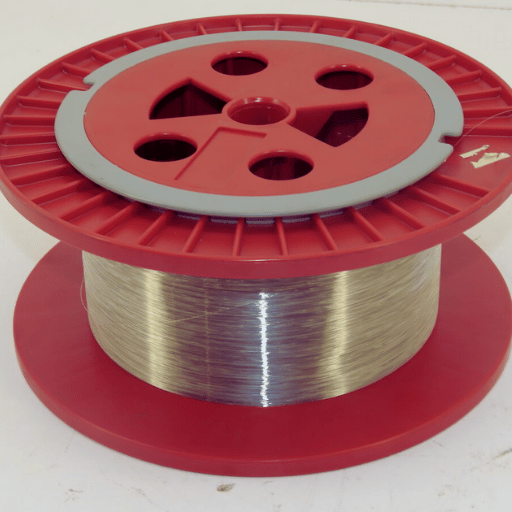

Bare fiber is essential in network installations due to its accuracy and detail in optical communication systems. It is also versatile, which enables its application in various fields. One such usage is in a testing environment, where it evaluates the performance of multiple components such as transceivers, amplifiers, or connectors. This guarantees that all components suit the data transmission levels required for use.

Another efficient use of bare fiber is temporary network setups. During a convention or live broadcasting, it is known to provide high-speed links in record time without extensive installation of cable wires, making it extremely useful for such events.

Bare fibers act as the medium between network cables in splicing operations. Furthermore, precise splicing significantly improves signal attenuation levels and data continuity. Newer splicing technology has drastically improved loss rates to lower than 0.1 dB insertion losses.

Bare fibers can also be utilized by researchers and developers. Optical researchers often depend on bare fiber to experiment with wavelength transmission, fiber mode testing, and complex multiplexing expansion for broadband and next-generation networking.

Recent estimates suggest the global fiber optics market is expected to expand annually by 8.5%. This statistic highlights the growing demand for efficient bare fiber solutions as network infrastructures grow and evolve. Such applications illustrate the importance of bare fiber in achieving flexible, dependable, and high-performance network systems.

Fiber spools have distinct advantages in optical networks, which improve their reliability and efficiency:

Without any doubt, fiber spools serve as the foundation for easy and flexible, high-quality optical networking systems.

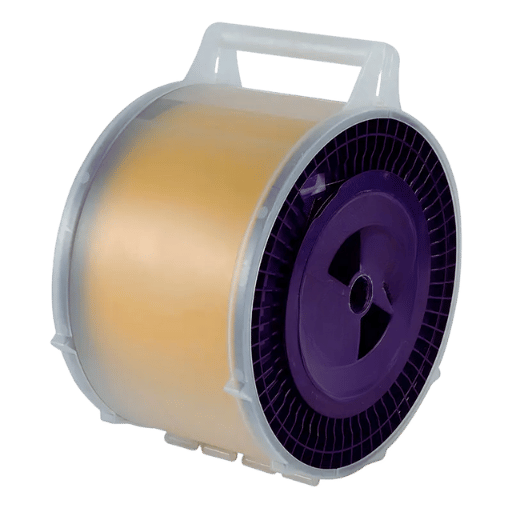

Compact fiber spools are useful IoT tools as they help save space in the setting of a modern network. These spools are perfect for scarce space, like data centers and telecommunication hubs, as they minimize the physical footprint. According to industry research, smaller fiber spools offer the possibility of up to 50% reduction in storage and installation space compared to the traditional spooling methods. This enables a denser arrangement of equipment without performance loss. Besides, their streamlined design aids in better cable management, thus mitigating the risk of tangling or bending radius violations that can negatively hamper the integrity of fiber optic signals. The result is optimized workflows and enhanced storage in limited infrastructure environments.

Compact fiber spools make the installation procedure easier. These devices increase efficiency in handling the spools while reducing the required setup time. Their weight and compact size enhance mobility, facilitating swifter deployments in congested or difficult locations. Furthermore, the streamlined spooling method minimizes the chance of tangles or other blockages in the setup, guaranteeing constant signal quality. All of these advantages result in greater efficiency and reliability when integrating fiber optic systems into contemporary infrastructure.

While installing, a common problem I face is ensuring that the cable’s minimum bend radius is not exceeded, as it results in signal distortion and physical damage. I pay extra attention to the manufacturer’s guidelines and handling tools to counter this. Another recurring problem is inadvertent cable stretching and squashing when obstructions like guides and fasteners are mislocated. I counter this by checking the intended route and approved guides and fixtures. Finally, signal loss can result if the terminations are not completed correctly. I want to fix this by cutting tools and performing rigorous tests for signals directly after the connection’s completion. Being consistent with these practices ensures a smooth installation process.

A: Optical fiber spools make it easy to store, handle, and deploy fiber cables like simplex bare fiber, plenum bulk fiber, and armored fiber cables. They can store cables in varying lengths. Optical fiber spools are extensively used in optical manufacturing and servicing to guarantee quality control and easier deployment.

A: Fiber spools come in various configurations to support single mode, multimode, bend insensitive, and breakout fiber cables. The spools also protect the fibers from damage, which sustains their integrity.

A: Spool sizes depend on the project requirements. Bare fiber spans of 250um are standard, but more complex installations require larger sizes. OptiConcepts’ bare fiber spools are flexible in installation and storage and designed to fit specific needs.

A: Reel solutions and fiber spools, for instance, make it easier to manage fiber cables during deployment and maintenance. These spools mitigate foiling and damage hacks and make the work of engineers deploying fiber patch cables and fiber pigtails more effective.

A: Fiber spools aid in quality overload controls because they allow the measurements and testing of fibers before deployment to be well managed. They also create an organized method of handling fibers, essential for fibers used for quality control within optical manufacturing.

A: Connectors are components that connect fiber spools to a network. In this capacity, they facilitate the interconnection of fiber patch cables or other network devices, helping maintain the required performance parameters of the data network.

A: Optical fiber spools can be customized to combine specific armored protection or plenum ratings with the length or type of fibers needed for particular engineering tasks. This enables them to fulfill the exact requirements of different engineering projects.

A: An Optical Time Domain Reflectometer (OTDR) is used for testing with fiber spools, as it measures, lists the optical fiber’s length, and evaluates loss while detecting faults. This aids engineers in guaranteeing the reliability and performance of the fiber optic installations.

A: Enclosures are accessible to safeguard fiber spools against environmental factors and even physical damage. Such enclosures greatly benefit locations where the fiber may be subjected to stringent conditions, as they help enhance the life span and efficacy of the fiber cables.

1. “Fiber optic payout assembly including cable spool” by S. Kowalczyk et al. (2018)

2. “Study on inner tension distribution of fiber optic cable spool with structure limitation of end plates on both sides for underwater communication in Winding Process.” By Weidong Liu et al. (2017)

3. “Design and Performance Analysis of a Fiber Optic Ring Heat-off Spool” authored by Yang Han-rui et al. (2017)