The need for a faster, dependable network has become a highly sought-after resource in our times, with the world becoming increasingly technology-oriented. Pre-termination of fiber optic cable assemblies is a helpful and versatile way to simplify the network infrastructure deployment, especially in multi-mode applications. These assemblies are easy to use, quick to install, and allow for reduced on-site terminations, decreasing error rates. This article describes the general principles regarding pre-terminated fiber optic cable solutions for multimode networks, their advantages and application features, and their potential for integration in the already existing network systems. A deep exploration of these issues enables the specialists and other representatives of the industry to look for ways of improving the network performance and cutting expenses while maintaining high operational flexibility.

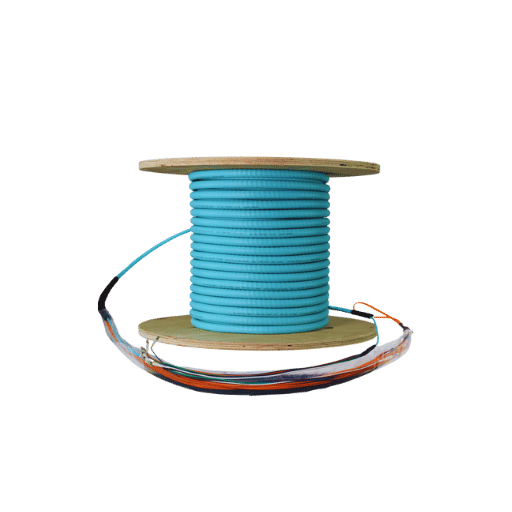

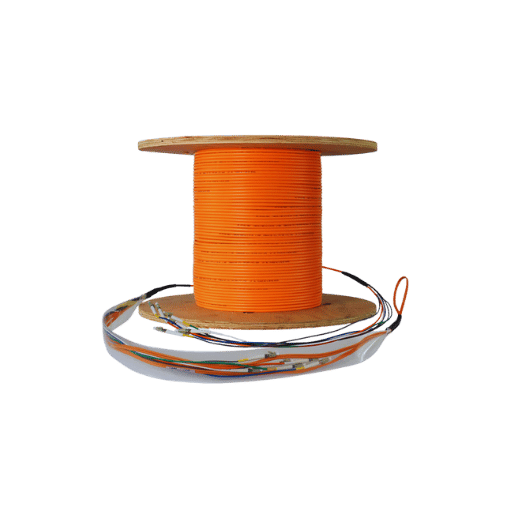

Fibre optic cable assemblies are pre-fabricated and comprise a complete end-to-end optical network cable solution. These assemblies consist of factory-terminated fiber optic cables, ensuring high-quality and accurate joining. Termination at the factory level reduces the need for splicing and installing connectors at the site, thereby reducing the likely field installation mistakes and speeding up deployment. In multi-mode applications, these assemblies are very beneficial in that they aid in transmitting data over moderate distances albeit at a high bandwidth, hence their use in data centers and enterprise networks is commonplace.

There are certain benefits that pre-terminated fiber optic cables provide, and that’s why they are very popular in today’s network designs. To begin with, these cables save a lot of time because the pre-termination process ensures that cables are delivered ready to be fitted, lowering the labor and installation time. Additionally, these assemblies are built in a controlled environment, which optimizes precision and quality and thus reduces human error during installations, increasing reliability and performance. In addition, considering there is a reduced requirement for expensive splicing devices and qualified personnel on their installation, these types of cables can also be regarded as cost-effective solutions in various network environments. All in all, these advantages enhance the reliability and performance of the network, which corresponds to operational efficiency and scalability goals for data-centric applications.

Sino de-name hono that at and con contract. So, especially on highly density placed objects that serve as the point of interconnection of core, the switches of a database create servers and store contents located in devices quickly and reliably. These assemblies are optimal for structured cabling solutions because of their configurations and relocatability upon increasing network demand. Also, they are useful in post-disaster setups and in planning repeater stations where replacement of entirety is needed and faster performance is desired for devices. Using pre-terminated cables under modules allows easy routing and routing and troubleshooting of networks that suit modern data centers.

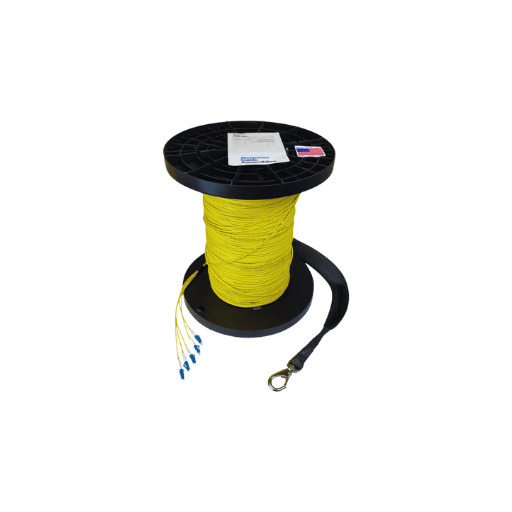

In determining what type of fiber optic cabling, singlemode or multimode, to go for, the application requirements and the network demands should be considered. A singlemode fiber has a core measuring approximately 8-10 micrometers and is used in situations where long-distance transmission has minimal attenuation and a maximum amount of data transfer. It is ideal for telecom and data center situations where the distance often spans several kilometers. In contrast, multimode fiber can transmit data over much greater distances (roughly 500m maximum), but this is mostly because its core diameter is wider at approximately 50-62.5 micrometers. Due to its simple alignment tolerance and lower transceiver cost, it offers low-cost solutions for connecting intra-building and local area networks. When selecting which type of fiber optic communication to use, singlemode or multimode, the structural requirements, the amount of available capital, and growth expectations or data transmission demand changes are the key factors to look out for.

The term connectors includes fiber LC, SC, and ST types. Fiber connectors attach fibers achingly into devices or to one another, maintaining signal and controlling input loss. System performance will be compromised, and reflection will be increased without proper connector selection and alignment. The number of strands also affects the flexibility and capacity of the network, where an increased number of strands allows more bandwidth and scalability. The proper splice and the attachment of high-grade fiber connectors on the fiber patch cords are appropriate for their application in modern network infrastructures that are quite complex.

Size, structure, and utilization are the main concepts that set the SC and LC connectors apart. Unlike these, the LC connector is smaller. It utilizes a push-pull latching mechanism similar to an RJ45 connector, allowing for stable and compact high-density connections because it is designed with a 125-ferrule. It is, therefore, suitable for use in data centers, among other applications where space allowance is a concern. On the other hand, the SC connector is designed with a more robust 25-ferrule, providing a slightly wider size scope. The connection works with a simple push-pull coupling mechanism but allows for applications in telecommunication that are denser, more rigid, and do not require a compact design. Connectors of both types can support singlemode and multimode fibers, but the decision of which to use boils down to the specific parameter requirements for space and cabling infrastructures for the network.

As it pertains to fiber optic communication assisting networks in transmitting data at very high speeds, both OM3 and OM4 cables are crucial in meeting the demands of the current network. These two are both classified as multimode fibers, designed for laser transmission with a diameter of the core of 50 um to enhance data transfer over short and intermediate distances. The main variance between OM3 and OM4 is based on their performance specification; hence, it was noted that OM3 can support 10 Gigabit Ethernet transmission over a distance of 300 meters and 40/100 Gigabit Ethernet up to a distance of 100 meters. At the same time, OM4 can increase these lengths up to 400 and 150 meters, respectively. OM4 cables are, therefore, better suited for regions where more performance and reach are required without losing bandwidth. These characteristics make OM specifications more important in the design of networks that are scalable and shark to help manage the ever-increasing flow rates of data in the future.

WideBand Multimode Fiber, or OM5, is the latest addition to a class of multimode fibers aimed at multiwavelength signal transmission – or, as the name suggests, wideband. Earlier OM fibers significantly increased the capability of multimode fibers by permitting the use of wavelength division in a single strand across all OMs. This would mean the potential for data transmission has increased in this regard. This fiberglass type is designed for high transmission speed over moderate distances for data centers and enterprise networks. The defining feature of the OM5 is the possibility of working with broadband wavelengths from 840 nm to 953 nm, which provides a higher usage of the available bandwidth. By supporting multispectral transmission, OM5 fibers would also bring down systemic costs, increasing the system’s application and suitability to changes in application growth and advancements in future data usage. Such a feature would indeed suit companies expecting robust growth in their data traffic and looking for cost-efficient improvements in their networks.

Plenum and riser-rated cables can be installed in places with a high fire safety code. Plenum-rated cables are designed and produced for sections that handle the passage of air from outside through the ceiling to the sides due to high smoke and flame redundancy. This feature reduces the chances of fire bursting, and low levels of smoke are produced in case of an emergency, increasing the chances of the buildings standing. However, riser-rated cables are also used in sections running between the floors or vertically oriented sections. They are built according to fire safety regulations to avoid combustion spreading through elevator shafts or conduits. The application of plenum and riser-rated cables allows for meeting the standard building codes and protecting structures and human lives by averting the spreading of smoke and fire at a high rate.

The decreased optical fibers are put in armored cables where adequacy is needed. Such cables contain a very firm, tough layer that covers delicate, thin glass fibers against physical tearing by rodents, force crushing, or impacts inflicted by persons. Introducing metallic or Kevlar armor strengthens the fibers to the point where they can endure environmental stress, rough handling during installation, and any other harsh conditions that standard fiber optics would succumb to. Additionally, armored cables are important for most industrial applications, outdoor uses, and places exposed to possible mechanical damage while maintaining perfect performance. With armored fiber optic cables, companies can protect their network base, minimize maintenance services, and guarantee access in hard weather conditions.

Tight buffer cables are important components of fiber optic installations where short-run indoor applications or environments with frequent handling and mechanical stress are encountered. The tight buffer configuration has a coating around each fiber, which increases tensile strength and makes handling, stripping, and termination processes easier. This added layer of protection is also helpful in minimizing the chances of tensile stress occurring during installation. Still, it reduces the number of components used in the installation set compared to loose tube designs. In this way, tight buffer cables are suitable for any application demanding high durability, simple interface, and fast plug-like installation, such as LANs, cloud-backed centers, and rolling-out networks.

When purchasing fiber assemblies coming from the US, one does not have to worry since such products are guaranteed to be of a high-quality level due to tough industry regulations and also the fact that these products are manufactured and engineered within rigorous performance and safety standards framework. Due to being ISO-certified, many US manufacturers conform to international standards within quality management. This compliance assures their clients that the products they will receive will be trustworthy and durable. Additionally, since working material and labor are both obtained locally, full control and accountability can be maintained throughout the production process, thus minimizing the chances of defects or variations occurring. US organizations gain enhanced reliability, better engineering, and great customer service by selecting US-made fiber assemblies, which only serve as a strategy best employed in preserving a robust working heritage fiber network.

Fiber assemblies made in the USA are very effective since they are guaranteed to comply with various regulations. Therefore, they can be relied upon because they have specific state and local guidelines. Depending on business standards, Compliance does ensure the safety of components and swiftness in doing business by putting regulatory all risks that surround business, including those associated with breaking or malfunctioning of networks, that is the solid offer of the components that are to be made. The legality of the components enables stringent assessment, testing, and validation of the components and network, assuring long-term reliability of the network and performance, too. All the same, switching out the fiber assemblies to being US-made with fiber assemblies being manufactured in the US guarantees continuity of operations, thus giving the organizations peace of mind knowing that their components have met all the performance criteria.

A: As fiber optic cables with both ends terminated with their required connectors, pre-terminated cable assemblies are one of the best solutions for instant deployment. In addition to saving termination time on-site, these readily available assemblies ensure uniform performance. They come in many types including multimode OM3 and others, LC fiber or MPO fiber optic connectors are provided as options to customize the assemblies.

A: Among other advantages, using pre-terminated fiber optic assemblies includes the following: 1. Speedier installation 2. Uniform and satisfactory performance 3. Minimization of termination mistakes on the field 4. Economical installation 5. Suitable for data centers and other densely populated applications 6. Can be ordered in precise sizes and shapes 7. It is excellent for headend termination to a fiber backbone.

A: Various pre-terminated fiber optic assemblies are available, such as 1. Multimode OM1, OM3, OM4 2. Single-mode 3. Ribbon fibre from 2 to 24 strands or more 4. Both riser and plenum rating 5. Available connectors include LC, SC, MPO, and others. 6. Made as per the specific requirement of the customer’s cables.

A: Riser-rated fiber optic cables are built to run inter-floors in non-plenum applications, while plenum-rated cables have been developed for use where there are spaces for air handling ducts. Compared to plenum-rated cables, riser-rated cables are stronger in terms of heat and will produce less harmful smoke.

A: Pre-terminated fiber optic cable assemblies with custom options, including fiber patch cords, are ready to meet your needs. These can include specifications such as the length of cords, types of connectors, density of fibers, and even bundles. Custom assemblies are best suited for odd jobs as well as standard jobs; there might be instances where no convention solution can work.

A: MPO (Multi-fiber Push On) fiber optic cables are high-density connectors with multiple fibers embedded in a single connector. Pre-terminated fiber optic assemblies in data centers are commonly constructed with MPO cables for high-density applications. They are great for numerous fibers because they are implantable, and they are backbone cables that provide metal connectors to network systems.

A: Fiber types can be selected based on the different requirements of the applications fiber uses. For instance, consider the following – 1. Distance Over Which The Cable Will Have To Be Run 2. The Bandwidth That The Setting Is Required To Support 3. The Speed Of The Network 4. The Infrastructure The Network Is Intended To Operate On 5. The Requirements Of The Network In The Future Some standard types would be multi-mode OM2 or OM3 for short distances and bulk data transfer or long distances for single-mode. It is recommended to ask a fiber specialist the best type suitable for the application.

A: To safeguard pre-terminated assemblies’ required quality and reliable performance, they must undergo testing procedures. This process commonly includes: 1. visually examining the China fiber optic connectors and cables; 2. Testing of attenuation or insertion loss; 3. Testing of excess loss or return loss; 4. Testing of the polarity of each fused fiber or MPO cable; 5. A test of fiber terminations or ends; 6. To measure the length of the fiber connectors. It is essential to understand that these tests guarantee that these natural apical assemblages have advanced technology structure and all functions as expected.

A: Pre-fiber optic cable assemblies are fibrous opt cables that are already equipped with connectors on both ends and thus are ready for use. These assemblies are perfect for quick and easy plug-and-play installation in a variety of network environments, including data centers, telecommunications, and enterprise networks.