A fiber connector is a device that joins two fiber optic cables together, allowing data to be transmitted between them. Fiber connectors are essential components of fiber optic communication systems, which use light to share information over long distances at high speeds.

A fiber connector is a mechanical device that connects two fiber optic cables, providing a means for transmitting data between them. Fiber connectors are used in various applications, including telecommunications, data centers, and industrial environments.

Fiber optic communication has become increasingly important in today’s digital world, providing a faster and more reliable means of transmitting data than traditional copper-based communication systems. Fiber connectors play a critical role in ensuring that fiber optic systems operate efficiently and reliably, as they enable the connection and disconnection of fiber optic cables without causing damage to the delicate optical fibers.

Fiber connectors align the ends of two fiber optic cables and hold them together using a series of mechanical components. The most important feature of a fiber connector is its precision ceramic ferrule, which ensures that the fiber cores are aligned with each other, allowing light to be transmitted through the fibers. This precision alignment is critical to the performance of the fiber optic system, as misalignment or contamination of the connector can cause significant signal loss and impair system performance.

Fiber connectors are typically made of high-quality materials with excellent durability and performance. The most common materials used in fiber connectors include ceramic, metal, and plastic. Ceramic is the most common material used for the ferrules, providing the best precision and reliability. In contrast, metals such as stainless steel are used for the connector body to give strength and durability.

One of the most significant advantages of using fiber connectors is their ability to provide a reliable and efficient means of transmitting data over long distances at high speeds. This is particularly important in telecommunications and data center applications, where fast and reliable data transmission is critical. In addition, fiber connectors provide easy installation and maintenance, making them ideal for use in a wide range of industrial applications. They also offer high bandwidth capabilities, allowing for greater data transmission capacity than traditional copper-based systems.

Fiber connectors are used in various industries and applications, including telecommunications, data centers, medical equipment, and industrial automation. In the telecommunications industry, fiber connectors connect fiber optic cables between network nodes, allowing for efficient and reliable data transmission over long distances. In data centers, fiber connectors connect servers and storage devices, providing a fast and reliable means of data transfer. In the medical industry, fiber connectors are used for endoscopy and other imaging applications, providing high-quality images for diagnosis and treatment. In industrial automation, fiber connectors are used for remote monitoring and control, providing real-time data feedback for increased efficiency and productivity.

When selecting a fiber connector, choosing a high-quality product compatible with the specific application and fiber type being used is essential. Proper installation is also critical, as improper installation can cause misalignment or contamination of the connector, resulting in signal loss. Regular maintenance is also necessary, as fiber connectors can become contaminated over time, causing reduced performance or failure. To maintain optimum performance, cleaning fiber connectors regularly and replacing any damaged or worn components as necessary is essential.

Fiber optic technology is becoming more common and is used to transmit data at extremely high speeds over long distances. Fiber connectors are an essential part of the process, providing a reliable and safe way to connect fiber optic cables.

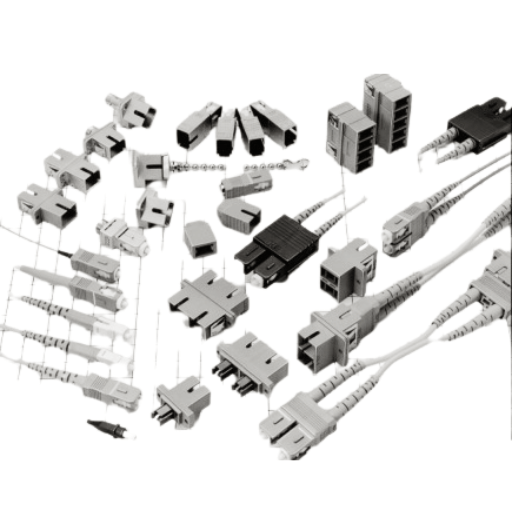

Fiber connectors come in various shapes and sizes, with each connector type having its specific features, advantages, and disadvantages, and appropriate use cases.

The LC connector, short for ‘Lucent Connector,’ is a small form-factor connector commonly used in data communication applications like Ethernet networks. It features an easy-to-use pull-tab mechanism for quick and straightforward installation and removal, which helps to reduce the possibility of cable damage.

LC connectors are known for their excellent performance and versatility in various applications, from high-speed data centers to residential and commercial installations. GIVEN ITS COMPACT SIZE AND LOW INSERTION LOSS, the LC connector is an ideal choice for high-density buildings.

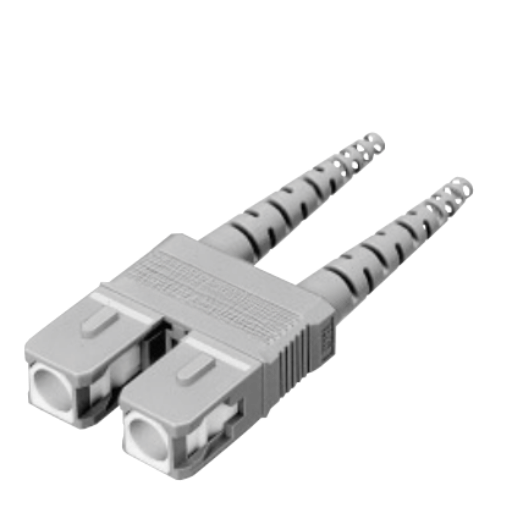

The SC connector, short for Subscriber Connector, is one of the most common connectors used in fiber optic networks. It is famous for fiber optic patch panels, wall plates, and desktops.

Compared to other connectors, the SC connector has a larger-tipped ferrule to prevent light loss and higher pulling strength to avoid cable damage. Its push-pull interface also makes it ideal for high-density installations.

The ST connector, or ‘Straight Tip’ connector, was one of the first connectors used in fiber optic networks. Its BNC-like bayonet locking mechanism provides excellent connection security.

The ST connector is reliable and straightforward, making it a popular choice for data centers and fiber installations. However, its bulkier design, lower insertion loss, and risk of dust contamination have led to a decline in popularity in recent years.

The FC connector, short for ‘Ferrule Connector,’ is one of the most common connectors used in single-mode fiber optic networks. It provides a stable, high-performance connection and is ideal for industrial and harsh environments.

The FC connector has a threaded connector interface that ensures a secure connection, making it ideal for mission-critical communication systems. However, it is bulkier than other connectors, making it challenging to install in high-density applications.

The MU connector, short for ‘Miniature Unit,’ is similar in design to the SC connector, but smaller in size. It is commonly used in high-density applications like communication systems and data centers.

The MU connector’s compact size is ideal for applications in which space is limited, and installation is complicated. However, its size can also make it challenging to use if extra care and attention are not taken when plugging and unplugging.

Installation and maintenance of fiber connectors require proper care and attention. The connectors must be handled with clean hands or gloves to avoid contamination or scratches, which could affect their performance.

Recommended Reading: Fiber Color Codes

Fiber connectors are an essential component in fiber optic networks, allowing for the seamless data transfer between devices. Different types of connectors exist, and it’s crucial to understand the distinctions between them to choose the most suitable connector for your application.

The LC connector is a small form factor connector used in single-mode and multimode fiber networks with a 1.25 mm ferrule. LC connectors are becoming increasingly popular in data centers and high-speed communication applications due to their smaller size, easy termination, and excellent performance. On the other hand, SC connectors are a popular connector type that uses a 2.5 mm ferrule. They were the first low-cost, high-performance connectors to hit the market. SC connectors are primarily used in single-mode applications but also some multimode networks. Lastly, the FC connector, a screw-type connector, is widespread in single-mode applications, where precision is crucial.

MTP connectors are multifiber in 12, 24, and 48 fiber configurations. Compared to other connector types, MTP connectors have a higher density, making them ideal for high-speed data transmission in data centers. Another critical advantage of MTP connectors is that they are quick, easy to install, and require minimal labor. MTP connectors are reliable and can handle high data rates and large data centers, making them an excellent choice for data centers, high-performance computing, and telecommunication networks.

E2000 connectors are small-form-factor connectors designed for high-speed optical networks. They have a spring-loaded shutter on the connector ferrule, protecting the fiber from dust and contamination. Excellent visual performance is delivered by the E2000 connector, making it suitable for high-speed data transmission, telecommunication, and data center applications. The E2000 connector’s locking system ensures a secure and reliable connection and prevents accidental disconnections.

MPO connectors are multi-fiber push-on/pull-off, creating fast and reliable high-density cabling. It has become an industry-standard connector in recent years due to its flexibility and modular design. Up to 12 fibers can be connected with one MPO connector, simplifying cabling and supporting high-bandwidth demands. MPO connectors are ideal for large data centers and telecommunication networks, making them one of the most sought-after connectors in the industry.

Single-mode and multimode fiber connectors are designed to use different fiber optic cables. Single-mode fiber generally has a smaller core size and provides higher bandwidth than multimode fiber. Single-mode fiber connectors are best suited for long-distance, high-speed networks, whereas multimode fiber connectors are ideal for short-distance networks due to their larger core size. Therefore, choosing the correct connector type is essential based on the type of fiber being used.

Every connector type has its advantages and disadvantages. The most important factors to consider when choosing a connector are its speed, fiber compatibility, and cost—understanding the differences between different connector types, from LC, SC, and FC to MTP, E2000, and MPO connectors, as well as single-mode and multimode fiber connectors. Whether you’re a network engineer, IT professional, or an end-user, having a solid understanding of connector types and their applications is crucial to maintain a reliable and efficient network.

Single-mode fiber connectors are used with cables with a single glass fiber strand to transmit data over long distances. The most common types of single-mode connectors include SC, LC, and FC. These connectors are designed to fit the specific cable type and transmit optical signals with shallow loss.

The SC connector is the most popular single-mode connector, with its square-shaped ferrule ensuring excellent element alignment, offering low insertion and return loss. LC connectors are also famous for their small size and ease of use, making them ideal for high-density environments like data centers. FC connectors are sturdy and suitable for critical applications requiring high-precision performance.

Recommended Reading: What is the difference between single-mode fiber and multi-mode fiber?

Multimode fibers are used with cables with several strands of glass fibers, making them suitable for shorter distances. The most common types of multimode fiber connectors include SC, ST, and LC. These connectors differ in design and performance and offer different features to meet specific application requirements.

The SC connector is the most commonly used multimode connector. Its ceramic ferrule provides precise core alignment and reduced back reflection. ST connectors are easy to use and connect with a twist-on, twist-off mechanism but are not as compact as the other connectors. LC connectors are small and easy to use, ideal for high-density environments. They are also known for their low insertion loss and high return loss.

Recommended Reading: Single Mode vs. Multimode Fiber

High-density environments require connectors that are compact and easy to use. LC connectors are the most suitable for high-density environments because they are small, easy to install, and provide excellent performance.

There are several factors to consider when selecting a fiber connector, including durability, ease of installation, maintenance requirements, and cost-effectiveness. Choosing a durable connector to withstand repeated connections and disconnections while maintaining high performance is critical. Ease of installation is also essential, especially when working in high-density environments with limited space.

Maintenance requirements should also be considered, as they vary depending on the connector type. Some connectors require more maintenance than others, which can increase the overall cost of ownership. Finally, cost-effectiveness is a critical factor to consider. While some connectors may offer the highest performance, they may not be the most cost-effective option for your application.

The performance and cost are the two main factors when comparing different fiber connectors. Connectors with the highest version typically cost more than those with average or below-average performance. Therefore, it’s essential to evaluate the specific requirements of your application before making a decision. Selecting a connector compatible with your fiber optic cable and network devices is also necessary.

However, just like any other technology, fiber connectors are not immune to issues that can affect their performance.

Dirty Connections: Dirt, dust, and debris can accumulate on fiber connectors over time, leading to signal loss and attenuation. Contamination can also lead to scratches on the connector’s surface, further degrading its performance.

Loose Connections: Loose connections can cause signal loss, cutouts, and intermittent connectivity. Over-tightening can also damage the connector.

Improper Connector Alignment: Misaligned or improperly aligned connectors can cause signal loss, attenuation, and reflections that can interrupt network performance.

Damage to Connector End Face: Scratches, chips, or cracks on the end face can reduce its performance.

Check the connector and make sure it is clean and free of debris.

Inspect the connector’s ferrule for damage, such as bends, chips, or cracks.

Check the connector’s mechanical connection, ensuring both connectors are correctly connected and tightened.

Use a visual fault locator to identify any breaks or losses in connectivity.

Avoid touching or handling the connectors’ end faces directly.

Use protective caps to keep connectors clean and to avoid contamination.

Use clean, non-abrasive wipes specifically designed for cleaning fiber optics. Avoid using alcohol, solvents, or other harsh cleaners that can damage the connectors.

Train users and staff on proper handling and maintenance techniques to prevent damage from improper use or storage.

Regularly inspect connectors for any signs of damage or wear and tear.

Clean connectors frequently using dry wipes or a cleaning solution designed for fiber optics.

Store connectors in a clean, dry environment, away from dust and moisture.

Use a microscope or magnifying glass to inspect the connectors’ surfaces for damage or contamination.

Temperature: Extreme temperatures can cause fiber connectors to expand or contract, leading to signal loss or attenuation.

Humidity: High humidity levels can cause corrosion and rust on connectors, leading to performance degradation.

Vibration: Excessive vibration can cause connectors to loosen, impacting their performance.

Connector Mating: Connecting and disconnecting connectors frequently can cause wear and tear, leading to reduced performance over time.

“Fiber connectors do not require cleaning.” This is untrue, as dirt and debris can accumulate on connectors over time, leading to performance degradation.

“Fiber connectors can be cleaned with any cleaning solution.” Wrong; using harsh cleaners can damage the connector and degrade its performance.

“If it’s clean, it’s good.” Not necessarily- even connectors that appear clean can have microscopic tissues on their surface, leading to signal loss and attenuation.

A: Fiber connector types refer to the various styles and designs of connectors used in fiber optic cables to enable the connection and disconnection of optical fibers.

A: A fiber optic connector is a mechanical device that aligns and connects two optical fibers end-to-end to create a continuous optical path for transmitting light signals.

A: Single-mode fiber has a smaller core size and can transmit only one mode of light, while multimode fiber has a larger core size and can transmit multiple ways simultaneously.

A: Some commonly used fiber optic connector types include LC, SC, ST, FC, MU, MTP, and E2000 connectors.

A: The LC connector is a small form factor connector commonly used in high-density fiber optic applications. It features a snap-in design and uses a ceramic ferrule to ensure precise alignment of the fibers.

A: The SC connector is a widespread connector used in both single-mode and multimode applications. It features a push-pull mechanism for easy insertion and removal of the connector.

A: The ST connector is a bayonet-style connector commonly used in older networks. It utilizes a metal sleeve and a spring-loaded ferrule for secure connections.

A: The FC connector is a screw-on connector that provides a stable and reliable connection. It is commonly used in high-vibration environments and for single-mode applications.

A: The MU connector is a small form factor similar to the LC connector. It is often used in high-density environments where space is limited.

A: The MTP connector, or the MPO connector, is a multi-fiber connector that can accommodate up to 24 fibers in a single connector. It is commonly used in data centers and high-speed networks.