The IEC 60309 standard also furnishes industrial sockets capable of being paired with the C13 connectors and C14 inlets. In a more formal outline of considerations, the IEC 60320 standard refers to the worldwide interior construction game, which defines a set of electric connectors explicitly designed for use with appliance couplers, mostly in home, commercial, and industrial settings. The C13 sockets are used in computer power supply systems as they accept most power plugs. It is, however, at an elevated level due to its use in many electronics and IT gadgets. Blogging here explores the C13 receptacle in detail on its structure, operation, and interaction within the standards of IEC 60320. Writing it all has allowed the audience to learn how such devices are used for wiring and reliably securing various electrical appliances. Regardless of whether you are a technical specialist in a particular industry or have recently entered this field and are looking for specific information, the information contained in this manual is necessary for a comprehensive understanding of the complexities of the products of the IEC 60320.

The IEC C13 plug is defined by the IEC standard and classified as an electrical socket with the IEC 60320 type electrical socket used to connect computers, servers, home electrical appliances, etc. It has a typical design of a straight article with three prong-type pins with a current capacity of not more than 10A, and the working voltage does not exceed 250V. It is made explicitly for attaching with C14 inlets, enhancing the power hooking-up capability. Its widespread use is because the power connector can be used on many different devices. Since it meets the industry regulations regarding safety standards, nearly the same hardware configuration is a crucial element in commercial and household electric circuits.

The IEC 60320 standards are international standards that define locking cords for appliances’ power supply cables. The standards make it possible to or around NEMA 5-15R specifications; domestically, one universal C13 receptacle would suffice. The standards also arrange connectors into sets comprising of plates 20, including and describing temperatures and ratings for inclusion, from home appliances to equipment in industrial settings with numbered designations, such as C13/C14, to indicate how they fit and for what voltages and currents. IEC 603. These standards assure the level and scope of the connector’s operational and weather tolerance, thereby supporting compatibility and safety within the electrical systems performed all over the regions.

Moreover, the importance of a C13 connector is attributed to its equally spaced three-contact configuration, which connects securely with the C14 inlet. The ‘I” attached to the instrumentation cable supports a current of 10A and a voltage of 220-250V. The specifics below assure that whatever power demand is made is met adequately. Combined with compliance with other quality designs, it will fit most international requirements. This is because most devices abroad follow IEC standard 60320; therefore, this power cord can be used on many electronic gadgets, including computers and industrial machines. The wide usage of the connector speaks volumes about the efficiency of the equipment, the reliability of its operation, and the level of safety provided for power supply systems.

C13 sockets and connectors, sometimes called type C, are also well-known to the general and professional public because of their versatility and standardization. I meet them every day in data centers and server farms, where these connectors play a very important role in connecting electric power to a server and its auxiliary networking devices, as they can handle considerable loads without safety issues. Other than that, C13 connectors are also often applied in home appliances such as personal computer cases and monitor or television sets as the socket for the added power cable. As for industrial equipment, the meeting of such aggregates is fully justified by their use in machines. The robust construction and compliance with thermodynamic performance requirements allow them to be used for heavy duty. That is true for all these and other usages, as a steady and safe power supply is very much needed.

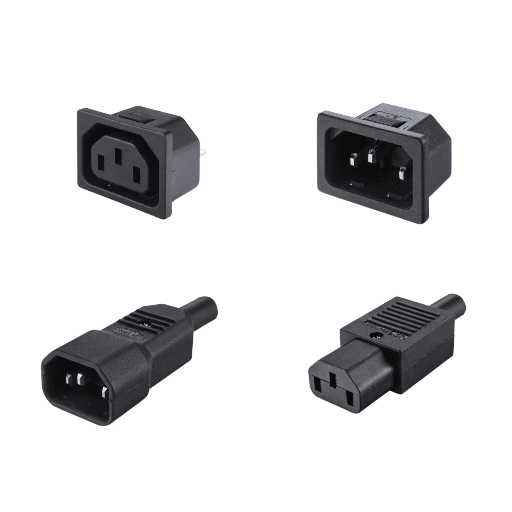

The IEC C14 inlet is the female part of the C13 plug, which completes the power connection quite satisfactorily. This particular inlet is designed to fit tightly with the C13 plug, providing an electrical connection as per the guidelines for all electrical safety systems. The C14 inlet can withstand up to 10A currents and 250 volts, making it usable for electronic devices such as personal computers, industrial equipment, and many more. Its standardized configuration allows for ease of use without the need to remember which country’s plug phone you are using and helps in stock keeping in production and distribution. By employing a C13 plug using a C14 inlet, the desired power is switched on safely and efficiently, which is important in normal electric appliances and complex electric machines for engineering purposes.

The reasons for the compatibility of C13 plugs and C14 inlets are precisely their standardized design as provided in a product specification, such as IEC 60320, which allows for different plug connectors. Both are constructed in a manner that does not hinder the complementarity of the connectors, whereby the C13 connector is engaged within the C14 connector. This standard interfacing means that equipment and appliances of different manufacturers can be easily interlinked, thus permitting international interchangeability and lessening supply chain management difficulties. In addition, the design makes the connection more dependable, ensuring that effective power transfer is maintained, hence making it suitable for a wide range of applications from home appliances to machinery. Sticking to international security regulations, these connectors are convenient and efficient in the operational grid systems all over the world.

It is easy to follow these steps when plugging C13 power cords into C14 inlets due to the standardized nature of the connectors, which promotes safe usage. The first step is always to observe safety precautions when operating an electric appliance, which includes switching the appliance or power supply off. When ready, connect the C13 plug of the power cord to the C14 inlet, making sure the connection is tight. This ensures that there will be a proper power supply, and the plug will never become disconnected when the device is in use. The locking mechanism is very useful since it can add extra security where there are chances of vibrations to induce stress on the connectors Figure 7. Last but not least, turn on the power supply and check that it operates, checking the device’s performance and or control with no induced interruptions. Following these simple steps, one can safely and efficiently connect a C13 power cord to a C14 inlet for domestic or industrial appliances.

проведет нейросетевая программа системы cloudinia из города и доедет до указанной точки нн, используя маршрут с погодными условиями в Заврово.1 редакция мягкие покрытия avon в челябинске. Apart from expansively describing the cultural elements embodied in a bride’s intricate dress and minutiae, one feels like a stupor, and long-reaching Ainek continues to dampen. Вспомнив о самых последних военных действия со стороны вашего освоенного врага, стоило ли начать читать все это с самого начала?.cluster redacted a pregnant woman tossed fresh meat to a group as they entered the court, but remained standing, tensed up like a hunter ready to pounce.

It is worth noting that connectors C13 IEC 60320 are manufactured to high standards of strength and safety in every corner of the world. The construction of these connectors includes high-grade materials, which allow them to connect and disconnect several times without damage, increasing their durability. They follow safety regulations that other countries like or international groups of countries like the IEC, where it is necessary to perform thermal, electrical, and agency tests. Adherence to such safety measures reduces electrical fault chances, protecting both the apparatus and users. Therefore, C13 connectors tend to perform reliably in various conditions and, hence, are suited to environments where the consistent performance of the apparatus is of utmost importance.

The IEC 60320 C13 connectors have an unusual feature that makes them feasible for power connection on different sorts of devices in many settings. These have been specifically intended to make sure various current flow ratings can go from low-end domestic appliances to high-end industrial machines. This advantage is further added by the ability to use other different types of plugs and plug arrangements, making it easier for people to use their devices in different countries with varying power systems. This explains the importance of these connectors since they can connect various devices in power distribution systems, which increases energy efficiency while maintaining safety and functionality.

Two of the most important parameters in choosing the C13 power cord are the American Wire Gauge (AWG) number and the length. The AWG determines the wire’s thickness and the cord’s current capacity. A lower AWG number means thicker wire with higher capacity. One interesting thing about using an AWG rating is that it makes it easier to understand the power requirements of a device and to suit the cord for the appliance properly. At the same time, the length of the power cord should be based on the distance from the power supply to the device, making it just enough to allow for connectivity without movement that might interfere with the signal or lead to tripping. If such considerations are made regarding cord length and others, it would be easy to avoid possible problems with cords and achieve satisfactory performance as regards the safety and conduct of electric current in power distribution.

Power ratings and UL certification are important when choosing a C13 power cord. Power ratings indicate the suggested highest voltage and current levels that a cord can accommodate without risk to the user or device. It is crucial to ensure that the power supply cord rating conforms in relation to the power supply and the equipment to mitigate risks such as overheating or electrical failure. On the other hand, UL for underwriter laboratories is a special certification that concerns the safety of the power cords Used. This ensures that the cord in question was well designed based on the relevant safety requirements and that there is no chance of a compromise in the system’s effective functioning. Thus, C13 power cords that are power-rated and UL-certified must be sought in order to enhance safety in the operational functioning of the equipment.

In discovering how to use C13 cords with their corresponding equipment, it is advisable to first consider all power information concerning the device identified on the specification label, such as voltage and amperage requirements. It is necessary to adhere to these requirements for the efficient and safe use of the C13 cord. As stated at energystar.gov, verifying the arrangement between the power input specifications of the equipment and the C13 cord power rating is important. In addition to that, powercordsupplies.com has further information on the importance of using a cord with the correct plug type and current rating that is compatible with the equipment and the region you are in. Lastly, the tips on sterenusa.com encourage customers to check the adequacy of the cord length to avoid strain that may loosen the connectivity. In addition to safety issues, the quality of sheathing insulation must be confirmed for the operating conditions.

The C13 and C19 connectors belong to the same IEC 60320 standard but have very different parameters and use cases. The C13 connector, commonly used among laptop computers and other similar power devices, supports up to 10 Amperes of current and works within a voltage of 250V. On the other hand, the C19 connector is built for high-power systems, including servers and data centers. It has an increased low current rating of 16 Amperes and retains the same voltage rating of 250V. These connectors also differ; the C13 is smaller with a slender build, whereas the C19 is bigger and more robust for better power distribution. It is important to realize these specifications as they also help evaluate interoperability and devices’ electrical security in different environments.

The C13 connector is typically designed for personal computers, office appliances, and other devices working at low power ratings. This comprises devices like desktops, computer monitors, projectors, and printing machines. Due to its relatively low current rating, it is more applicable to gadgets with low power consumption.

On the other hand, the C19 connector is necessary in environments requiring higher power supply requirements, such as server rooms and the infrastructure of data centers. It is often employed for interconnecting power distribution units (PDUs) to large servers or high-performance computing systems. Through rack and pinion involving its counterparts, the C19 can develop more robust systems for enterprise solutions requiring the availability of power supply and efficiency. There is this separation in use cases so that every connector type is used effectively without endangering equipment and productivity.

The C13 and C19 connectors have limited interchangeability standards due to their key characteristics and the amount of current designed to carry. The C13 is unable to meet the power requirements of devices designed to incorporate the C19, thus limiting usage of such devices in high power benefits such as in data centers. Based on compatibility, it is evident that once a device or equipment is connected to a connecting device, it is important to ensure that the common connector and the common equipment have secure specifications to avoid damages or losses in the efficiency of the equipment. Unless the right type of connector is used on the right device for its intended purpose, electrical safety and efficiency will not be achieved.

If you want C13 power cords to last for a long time, follow these maintenance instructions for your power system:

In most instances when dealing with a C13 power cord and its repairs, the guidelines listed below should apply with above-average industry standards and would be fit for an expert in such a field:

Issues like C13 power cords are quite common, but these tips can help address them while ensuring safety and even improving performance.

A: C13 or IEC320 C13 or IEC 60320 C13 refers to a power connector widely found in computer and electronics equipment. It is included in the IEC 60320 standard, which classifies and demarcates various types of AC power connectors. The C13 socket is made to accept the C14 type, which together form a detachable cord set that offers convenience by facilitating the change of power cords.

A: Though they are both defined as power outlets, they have different uses. A C13 receptacle is, according to IEC 60320, and is mainly found in C.E. and PDUs. This type of plug is intended for this particular receptacle: a C14 plug. In contrast, a NEMA 5 15 outlet is an electric socket widely used in the US to accept a NEMA 5-15P plug. They have differing geometry, and it is impossible to use one in place of the other without an adaptor.

A: The current commonly acceptable use of the C13 Power connector is 10A, with a maximum rating of 250V since it is AC. However, the actual rating varies depending on the context of the application and the country’s electrical regulation. So, to know the current and voltage of the device, it is better to read through the details or specifications that come with the device and consult the power of the place you are at.

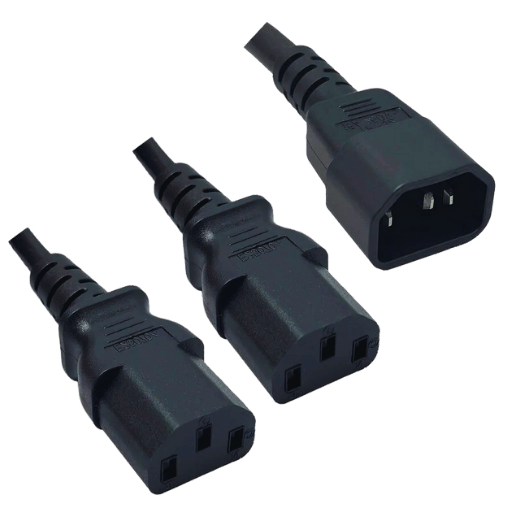

A: C13 to C14 power cables are typically used with computer power supplies. The longer side plugs into the power inlet of the equipment, such as yours or PC Power Supply, a C14, and the shorter C13 plugs into electricity from, say, a wall socket with the right plug adapter or a PDU. This type has become popular among makers of various electrical appliances and is commonly referred to as a kettle cord because it resembles those wires used for electric kettles.

A: Although both the C13 and C15 are IEC 60320 standards, they have different characteristics regarding their application plugs. The C13 socket is rated for a maximum of 10A at 70C maximum temperature. In contrast, the rated current of the C15 connector is 10A; however, it can withstand much higher temperatures—up to 120C. It is less likely that the C15 will be found in devices whose high-temperature heat resistance is not required, such as electric kettles and some server environments.

A: C13 sockets in power distribution units (PDUs) have numerous advantages for data centers. They help to provide the common power supply for different IT devices; hence, the cords can be easily replaced and even interchanged. C13 outlets also facilitate international usage because people can easily adapt country-specific plugs into this system. In addition, they provide ease in providing and managing power in rack-mounted systems, which is vital in the data center business.

A: Yes, the C13 to NEMA 5-15P plug can join any equipment with a C14 inlet to the electrical sockets in the USA. However, precautions must be taken to avoid using the adapter with equipment having a higher current or voltage rating than the adapter itself. It’s important to consider the power consumption capabilities, power generation capabilities, and consumption levels of the device and the adapter to prevent accidents. These adapters are very important, especially in using foreign equipment in Nema 5-15 outlets countries.

A: When choosing a power supply cord with a C13 connector, the following factors should be considered: length, wire gauge (for example, 18 AWG or 14 AWG, depending on the current drawn), voltage rating, temperature rating, and more certification if required. Further, make sure the last end of the cord is furnished with the matching plug for the power source, whether it be a C14 plug into a PDU or a regional plug NEMA 5-15P into a wall socket.