In the realm of data centers and IT infrastructure, C14 to C13 power cables are a prevailing element. Facing the challenge of providing power and connections to networking devices like servers and power distribution units (PDUs), these cables are helpful in power management strategies as well as minimizing chances for loss of uptime owing to electrical problems. The article intends to cover in detail such features, areas of use, and other merits of C14 to C13 power cables so that readers would know the trends pertaining to the usage of these cables in today’s technology environment. This guide will, therefore, be beneficial in learning why such power cables are critical in power distribution and enhancing IT management, whether a person is in the information technology field or even a layman who just wants to know more about power cables.

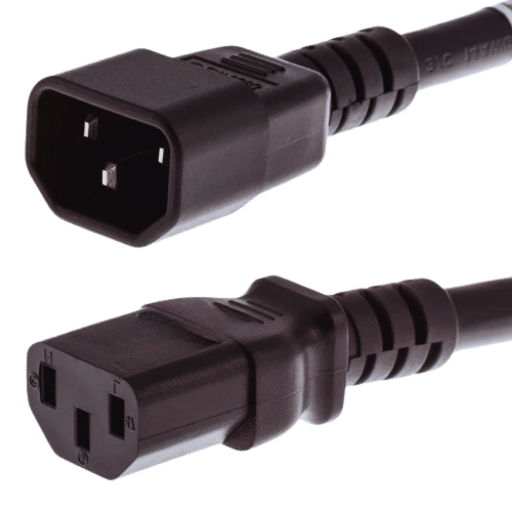

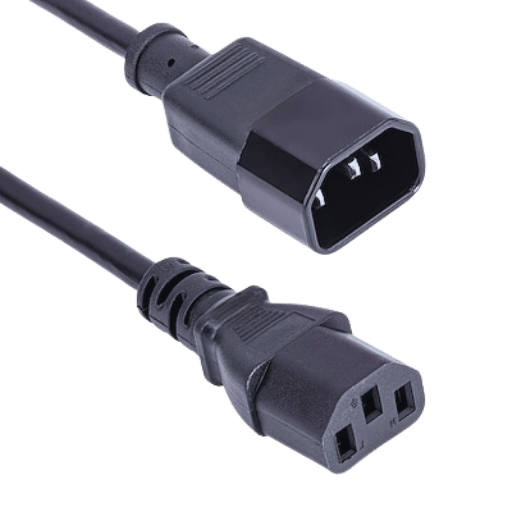

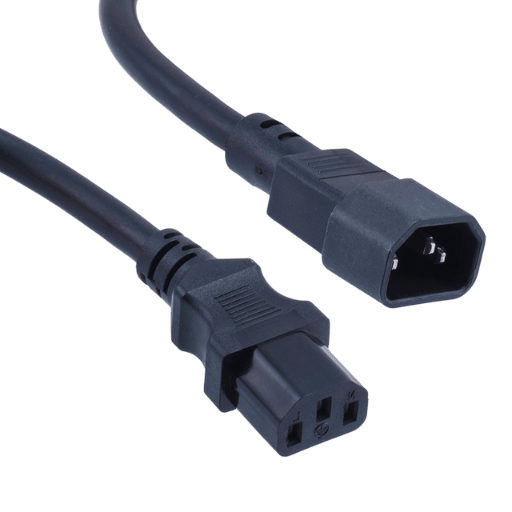

The C14 to C13 power cord is an electrical connection cord that serves to link up a C14 inlet situated on power supply units to a C13 socket located on computers and other networking equipment. Such cables configuration is critical in ensuring and distribution of AC power from power distribution units to associated IT equipment prospect.

The C14 connectors resemble those female parts but are of a male type and are commonly found on the power cords of power supply units, equipment harnesses, and other devices requiring a main connection. Typically, three pins and battery plugs are meant for up to 10A, 250V, AC electrical power. On the opposite end, C13 connectors are typical female sockets used to provide electric power to the IT networks’ constituent parts such as computers, monitors, and other devices: they fit C14 power plugs and provide no more than 10A, 250V. These types of connectors guarantee the interconnection of various devices as well as the uniformity and organization of power supply circuitry for the IT systems.

C14 to C13 power cords are widely used in data centers, server farms, and office IT systems. These cords are used primarily to extend power distribution units (PDU) to IT devices, including but not limited to servers, switches, and other networking devices. This connection is very significant in contributing to the efficiency and availability of networks and systems. Capable of carrying currents of up to 10 amperes and voltage levels of up to 250 volts, these cords suit various equipment parameters. The universal structure of the connectors C14 to C13 makes it easy to achieve complex system performance without escalating the integration expenses since it allows for easy additions or redisposition of the components. Additionally, through the use of these cords, organizations can achieve international standards of electrical wiring; hence, safety and reliability across operations can be achieved.

The C13 and C14 connectors are IEC 60320 connectors; however, they are designed to perform different yet interrelated roles in the provision of power supply. The C13 connector, a female fixing, is normally used on power cords or connecting equipment and is connected with the male C14 plug, which is commonly built into the power supply unit. This type of connection enhances safety by preventing incorrect or loose connections to external devices and thus provides a steady power supply necessary for various appliances, including computers, servers, and networking devices. Thus, the main difference is in the orientation of how current enters or leaves; the C13 is a plug where power comes in, and the C14 is how power goes out. Both connectors are designed to work under the same maximum current and voltage rating of 10 A and 250V respectively, respectively; the position of the devices varies, making them useful everywhere electrical systems are set up.

In figuring out a C14 to C13 power cord, it is worth checking the voltage and current ratings so as not to make the wrong choice and preserve the operating safety requirements. C13 and C14 connectors can endure up to 250 volts and 10 amperes of power, making them applicable to several appliances, from personal computers to industrial machines. In other words, that power cable has a rating in terms of load capacity such that it is defined by electrical safety standards of onset overheating.

It is also important to ensure that these levels are not exceeded by the connected load because the device under power harmonics can lead to a breakdown of the insulation and even more catastrophic failure. In addition, evidence should be submitted on environmental circumstances such as ambient temperatures and the operational load time as they affect cable performance endurance. Installing cables within the rated parameters protects equipment while enhancing operational effectiveness and efficiency. The connectors’ 250V and 10A operational ratings are a compromise between providing a good amount of power and the ability of the connectors to last, hence their reliability in different scenarios.

The specifications of the American Wire Gauge (AWG), or more particularly the AWG sizing a cable should possess, is important because it determines the design current of that wire and the overall efficiency of the system in relation to the purpose intended irrespective of the heating losses induced at the wire. AWG or American Wire Gauge is contrarily related to the cross-sectional area of the wire; hence, the lesser the AWG number, the thicker wires are used as they are expected to carry more loads with lesser power losses. Properly Choosing an AWG power rating helps to ensure that the heat produced, if any, is not sufficient to cause the cable to burn out even when the device is operating well, in effect eliminating huge troughs in voltage and other risks. This goes hand in hand with what this writer has stated so far: suitable standards, if adhered to, will increase the safety and performance of the electrical system, thereby protecting and extending the useful life of systems in use.

It is important to determine the application requirements and environmental factors when it comes to choosing either SJT cables or other types of power cables. SJT(Cable) or Service Junior Thermoplastic has a moderate usage environment, close to general usage, e.g., portable equipment and house appliances. These cables incorporate thermoplastic insulation with a maximum service temperature of 60 degrees Celsius, along with certain oil and grease resistance. However, in case of those environments where somehow oil and water exposures or extreme temperatures would have to be dealt with, a different form of cable, for example, SOOW or SJEOOW, would be chosen. In particular, SOOW, which stands for Service Oil Resistant Rough Tough, is very helpful in areas that require a lot of rough environmental conditions and tough chemicals. Hence, the choice of the cable applies to the appropriate operational requirements and hazards as they should provide effectiveness and adhere to the electric standards.

The adoption of a C14 to C13 10A 250V power extension leads to increased effectiveness and flexibility of power distribution in data centers. These cords are aimed at connecting the power distribution units (PDUs) to the server racks and in doing so ensures a neat and efficient method of supplying power. Its tough construction allows for a maximum operation current of 250V and a maximum current of 10A, placing it in a good position as far as most IT devices are concerned.

The availability of such cords will help in better organization of the cables and in maintaining too much cable, which is very important in high-density server deployments. Additionally, they allow the reorganization of the infrastructure or, alternatively, further expansion of the infrastructure without the consistent expense of rewiring or the risk of equipment failure owing to insufficient power supply. Research in other countries indicates that the use of appropriate power cord management may translate to up to 20% of operational cost losses due to downtime and poorly executed equipment management during maintenance. Therefore, incorporating C14 to C13 power cords is relevant in increasing power efficiency in modern data centers.

Power Distribution Units (PDUs) are critical for enhancing the efficiency of electric power utilization within data centers since they serve as opportunities for power consumption for several devices from one power outlet. Installing C14 to C13 power cords is, of course, a delicate exercise, which PDUs make easier since they centralize the control and routing of power. They are constructed in such a way that power is not wasted in the process of supplying power to various pieces of equipment. They also transform the credibility of power supply in a way that helps in cable management using C14 to C13 power cords, which improves heating issues, accessibility, and maintenance. This, however, allows the data center facilities to expand without needing a complete overhaul of the whole infrastructure. PDUs improve the efficiency of operations in the enterprise by adding monitoring features that allow for the management of the power used in the enterprise. The careful operating conditions of both PDUs and C14 to C13 power cords create a sustainable and flexible power structure within a data center.

UL (Underwriters Laboratories) and RoHS (Restriction of Hazardous Substances) certifications are vital in avoiding potential hazards to human health and the environment regarding such electrical components as power cords with IEC320 C14 to C13 plugs. Getting a UL certification denotes a product that has gone through a battery of rigorous tests and has been found to meet set standards of the industry’s best practices. This regulatory process is responsible for assessing the properties of electrical disposal that insulate from ignition and burning, which could create emergencies when used in data centers.

However, compliance with RoHS allows for the avoidance of the presence of certain hazardous materials that are normally present in electrical and electronic Equipment. Such materials comprise lead, mercury, cadmium, and a range of flame retardant materials, which have large amounts of biomedical and environmental problems. Adherence to RoHS is also very important for manufacturers who would like to be eco-friendly, as all their products comply with the EU CRC on the banning of some materials.

In addition, UL and RoHS certification data is in the public domain and can be of assistance to data center managers in relation to the acquisition and upkeep of power cords. The use of these certified products ensures that the operations of a data center are safe and compliant with the regulations, and it promotes the vision of sustainable operations. Data centers can achieve these operational efficiencies and at the same time carry out their work in an environmentally friendly manner by knowing and implementing UL and RoHS standards.

In order to reap the benefits from a setup, using compliant cables is important and needed for one reason in particular, and that is for safety, reliability, and environmental responsibility. Cables that are complied with go through total verification like UL and RoHS, which means that they can be relied upon to work under strict conditions. This lowers the chance of malfunctions such as excessive heat or fire from electricity, thereby safeguarding both the devices and the people. Also, it is necessary to observe the RoHS directive and use nonhazardous material in the cables, and therefore, the health risks and environmental impact are reduced. At the end of the day, using compliant cables is also beneficial in the sense that it promotes return on investment development in relation to proper management of the data center and its overall system integrity and efficacy.

Best practices of cable management and maintenance help in guaranteeing life and efficiency of power cables of C14 to C13 range. First, it is very important to ensure that cables are checked periodically for any signs of deterioration such as fraying or cracking that compromise safety and reliability. It is advisable to carry out the inspection after every three months or shorter for more busy environments.

Second, avoid bends and maintain proper arrangements when routing cables; for instance, avoid stacking them with others to avoid bottling up some of them, which is harmful with time. Besides using clips, ties, and organizers engineered for laptop systems, cable management offers cushioned stress relief for the connectors as cabling methods are in place.

Also, potential places and conditions that will host them have to be preserved. Electric power cables should not be placed near excess heat general or through too much moisture because such conditions greatly deteriorate the materials used in making cables. These cables can ideally be kept and used within the temperature band of 20°c and 25°c, while the humidity should be between thirty percent and fifty.

In conclusion, one more practice that ought to be implemented is to look out for the power loads not being above the approved load for the cables. C14 to C13 cables HDP 160 can limit reaching a 10A at 250V AC. Conducting load checks on cables supports securing the specifications with active erring, reducing several risk factors such as burning, breakdown, or overheating. All repairs and compliance with these requirements should be aimed at preventing the effective operation and safety of power cables C14 to C13 in data centers.

When it comes to buying C14 to C13 power cords, Amazon, Newegg and Best buy are some of the leading companies for consumers to purchase from. Such platforms provide a range of options and also sell cords of varying lengths and specifications at competitive prices. Furthermore, industrial residual-grade cords can also be purchased from most electronic wholesalers such as Mouser Electronics and Arrow Electronics.

When you adhere to these steps, it is possible to achieve the safe and correct installation of the C14 to C13 power cables, which will further ensure the ideal performance of your equipment.

A: Most commonly, this C14 to C13 power cable is used for connection of the computers, monitors and other sorts of devices to power supply. They are constructed in a way to allow stable transmission of the power which is important for configurations that need reliable power paths.

A: 15A on a power cable means it has its amperage rating of 15 amps usage and that is the maximum and worst case scenario. This is an essential specification in trying to ascertain that the power cable will withstand all the devices being plugged and connected into it.

A: C13 is usually the female contact end at the tip of power cords used to connect to computers and other electrical devices, while C14 is the male end usually plugged into power supply units and power distribution units. Two of the above connectors form the C14 to C13 female-to-male connector assembly.

A: Black is the most common color used for power cords because it helps these cords to match different surroundings and make them less visible, which is crucial particularly in working environments. It also takes some time before the black cords become spoiled by dust and other usages after which they become economical for use.

A: The IEC C13 power cord is important as it enables the use of multiple electrical devices across countries without the fear of them being potentially dangerous, as all conform to the required standards. It is seen inclusively with an array of equipment such as computers, monitors, and many other electronics.

A: The standard size C14 to C13 power cable is not fixed, but among the standard ones we have, it would include 1ft, 2ft, 5ft, and even 10ft if need be. The length you will need is determined by the arrangement of things and especially the distance from the power wire to the device.

A: In a standard data center, a PDU power cord is used to provide power to various devices through a Power Distribution Unit (PDU). These specialty cords are that they allow power to run to many devices from one source.

A: Part Number is described as the one that is used to classify data cables of specific power cable model. This helps manufacturers, retailers, and consumers to accurately identify and reference the exact product they need.

A: A right angle C14 power cord is useful for narrow areas as straight connector cables may even prove useless. It permits better management of the cable, reducing strain on the connection points which may extend the lifetime of the cable and the port in which the cable is fitt ed.