When it comes to contemporary telecommunication or delivering data services over the internet through data centers, the management and arrangement of fiber optic cables are valuable in ensuring that the network is functioning optimally and is scalable. A fiber patch panel is essential in assisting with this issue as it provides a systematic method of terminating, connecting and organizing fiber optic cables. This guide will focus on elucidating the aspects of the fiber patch panel, its accessories, the work done with such a device, and how to install it and prolong its service life. The author hopes that a clear understanding of the principles and fiber patch panel applications will prepare the reader to make rational and profound conclusions regarding using these items to construct a network infrastructure.

Fiber patch panels within fiber optic cable interconnects serve the same purpose: simultaneously clarifying, connecting, and managing several fiber optic cables in a unit. Decmpo Zayed et al. 2009. This makes it easier to alter or troubleshoot the connections as they act as a central point where all incoming and outgoing optic fibers are distributed through several ports and connectors (Gleeson et al. 1998). It is an interface that collects and systematically orders interconnections between fiber optic cables to manage networks effectively.

In any network restructuring, a passive device such as a fiber optic patch panel can be used. It provides a means to join several optical fibers into one plain place. It has a series of adapter panels and ports where the connectors of the fiber optic connectors plug in. The incoming and outgoing fiber optic cables can be connected to these adapters, which help in the proper routing of the signals via cross-connections. Network management, testing, and reconfiguration can be performed with fewer chances of service interruption. The patch panel’s physical structuring prevents signal loss, helps to avoid the destruction of cables, and simplifies the maintenance control procedures, which allows remarkable improvement of operational reliability and efficiency in the network.

Fiber patch panels are broadly divided into three categories based on their format, method of mounting, and type of connectors.

Mounting Method Based Types:

Proper choice of fiber patch panel depending on the certain needs of the network, allows the users of such a fiber optic infrastructure to attain great levels of performance, flexibility and scalability.

Fiber patch panels have the foremost advantages regarding the network’s managerial and optimization activities. In the first place, organization is improved, as it provides a proper layout of the fiber optic cables, thus avoiding tangles or disconnections. This organization also reduces the work needed during repair and necessary future alterations. Second, they are responsible for maintaining a stronghold of the fiber connections and limiting any physical and environmental damage to them. Moreover, patch panels help improve the cable arrangement, making optimal usage of the space available and, therefore, enhancing the adaptability of the network as it grows in size. In the end, this all results in better network efficiency as well as reliability and perhaps lifespan of the system due to the presence of the fiber patch panels used in modern fiber optic systems architectures.

A Fiber patch panel provides an orderly approach to connecting and routing fiber optic cables to enhance the proper management of the network. The organized system prevents any cable disarray, making it convenient to trace each connection. Since all the link points are centered around one location, disconnections are reduced, and inter- and re-configuration of network links is made easy. This neat arrangement makes it easy to fix and diagnose problems quite fast, which will optimize the network’s operations and minimize the network’s downtimes.

LC and SC connectors are generally installed to interconnect between fiber optic facilities or the ends of a fiber optic cable. LC connectors are small-sized vertical connectors that entail space efficiency, enabling high population density. They come with a connector housing design for effective connection without displacements. On the other hand, SC connectors are bigger in size than fiber pigtails but come in heavy handy with a straightforward push-pull coupling mechanism. They are quite efficient due to low levels of insertion loss and stability. The use of both LC and SC connectors is critical in achieving the targeted cognitive alignment, stability, and performance of fiber optic systems, enhancing the network’s effectiveness and reliability.

When buying a fiber patch panel, factors should be taken into consideration.

Considering these factors while selecting a fiber patch panel would ensure that the panel you are purchasing conforms to your network’s needs and improves performance and manageability.

When choosing singlemode fiber or multimode fiber, some factors both crucial and significant on the topic must be taken into consideration:

Transmission Distance and Bandwidth:

Singlemode Fiber: This fiber is best suited for long distances of several kilometers or more. It can offer more bandwidth and hence the niche of telecoms and data centers.

Multimode Fiber: Ideal for distances of less than 550 meters for most cases of today’s networks. However, this compares unfavors one mode in terms of range but tolerable for a few meters, data and video/audio applications.

Cost:

Singlemode Fiber: However, the inflated cost is usually on the immediate installation cost due to the splicing factors, which call for accuracy and expensive transceivers.

Multimode Fiber: More affordable for longer runs, where cost-effective LED-type transceivers are used and supporting structures less precise and therefore non-complex.

Applications and Use Cases:

Singlemode Fiber: Where the need for high mobility and increasingly high data rates is required. These modes of fiber are obtained as WANs in campus backbones and MANs, as well as Long-haul communication.

Multimode Fiber: Utilized in corporate LANs, data centers, and in short-range audio/video transmission where distances constantly tend to be less.

Installation and Maintenance:

Singlemode Fiber: This however, requires proper orientation and equipment as well which can translate to increased installation and maintenance costs.

Multimode Fiber: Simpler to install/maintain as less technical skill is required owing to the allowance of position possession caused by the bigger core diameter.

When you analyze your network’s distance criteria, budgetary policies, and application type, you can choose singlemode or multimode fiber.

What needs to be highlighted about 24 port LC and 48 fiber panels is their contribution towards efficient use of the telecommunications and data network. While the 24 port LC panel supports up to 12 connections made through fiber optic cables that are also supported with two fibers each for sending and receiving purposes, this type of patch panel is aimed at smaller networks or at areas of larger networks. On the other hand, a 48-fiber panel, which accommodates up to 24 fiber optic cables, is oriented towards a high–density design that allows for more network connections. The panels make it easier to organize the mess created by the cables, make it easier to maintain the system and allow it to grow without wasting space and resources in a network setting.

Since proper installation is key for working with a fiber patch panel, step-by-step processes should be observed.

If such steps are followed, a properly positioned fiber patch panel will be installed in an organized manner, enhancing the network’s operational capacity while making it easy to manage and maintain.

Fiber patch panels allow you to connect several optical fibers in the exact location. They are also known as multiplexers, connectors, and cabling networks. For efficiency and durability, fiber patch panels are managed and troubleshot following specific systematic procedures.

With such practices, it would be possible to ensure that the fiber patch panels are working correctly, any problems are rectified, and there is high and continuous network performance.

Fiber LGX adapter means low-gramming expansion functional direct connector casing, and critical body functional devices are comprised of increment cassettes. Adapter panels of LGX are provided for multiple mounting of fiber optic adapters, including simple connections of various fibers with low-loss connectors. Cassettes of LGX usually hold boost-engaged cable assemblies that include installed and tested micro coaxial cables, resulting in easy site work with less pollution and proper engagements. These parts allow a fast, easy, and, most importantly, reliable network infrastructure connection.

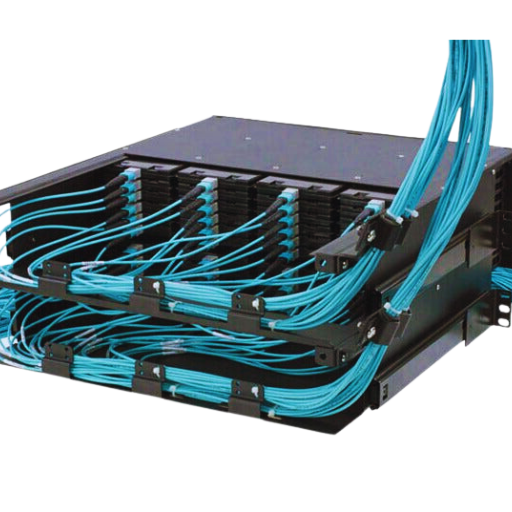

The use of rack-mount fiber enclosures entails several procedures that help organize and safeguard the fiber optic cables. The first step is to fit the enclosure properly in a standard 19-inch rack folding, ensuring it is properly aligned and, therefore, stable. Second, the incoming and outgoing fiber optic cables should be brought through the appropriate entry and exit points, and cable management accessories should be employed to prevent excessive bending of the cables. Thirdly, connect the incoming and outgoing fiber optic cables to the internal adapter panels or modules depending on the guidelines provided by the manufacturer. Finally, close up the enclosure doors or panels to prevent dust and other intrusion on the connections. The fiber network can, however, be inspected and maintained for performance improvement to increase the system’s durability.

Based on my work experiences, wall-mounted fiber distribution panels have a few specific advantages. First, such panels allow for the efficient use of floor space and are appropriate for compact or constrained areas such as telecommunication closets. Secondly, these types of structures are advantageous since they improve cable containment by preserving the fibers, thus lessening the chances of damage and ensuring a neat installation. Thirdly, wall mount panels are in a position to allow more maintenance and connections, requiring less time off for servicing, such as Cruz. They can also be placed on middle coordinates, such as on the walls at the level of the eyes, thus making fiber optic network maintenance easy.

OM3 and OM4 fibers are characterized as two types of multimode fiber cables intended for use in high-speed broadband transmission systems; however, they differ in their performance features and intended applications. There lies a more substantial distinction about the bandwidths. For instance, the bandwidth of OM3 fibers is 2500 MHz.km at 850 nm, while that of OM4 fibers is 4700 MHz.km (850 nm). The reason is that the OM4 will have to be constructed such that the reduction occurs more subtly within distances, which can be viewed as further distances from a wavelength. An example is that Conference by Note F 100 Gigabit Ethernet System is supported at 150m by OM4, whereas the maximum support of OM3 is 100 meters. Because of these characteristics, OM4 fibers are appropriate for more rational high-speed data networking applications that require further extension of reach. nced high-speed networking applications that require extended reach and performance.

Fiber optic enclosures could further enhance network performance by ensuring the safety and orderliness of the fiber optic cables and their connections and getting the best out of the aqua fibers management. They shield the fibers from mechanical impacts and other environmental interference, like dirt and high humidity, which optimize signal quality and mitigate signal losses. Enclosures distribute the cables in an orderly manner, which reduces the strain and the bends put on the wires, performing the function and eventually improving performance. Such enclosures also enhance the maintenance of the systems by providing quick access to the devices. This eliminates delays in maintenance and upgrading the network and aids in reliability.

Following fiber termination and splicing best practices enhances the network’s connectivity and reduces connectivity and OtDR losses. Appropriate connectors and tools for the fiber being terminated must be used in termination. Maintaining fiber optic cable cleanliness is crucial; all fiber ends should be cleaned thoroughly before a connection. Accuracy is also vital; ensuring the right cleaving and employing high-precision alignment tools greatly enhance performance.

End preparation is essential for splicing methods using fusion or mechanical fiber. Clean stripping, cleaning, and cleaving of the fiber are done to minimize splice losses. Fusion splice is the preferred joining because of its low connector loss and strong joint, embodying precise fiber alignment and optimal arc settings based on the fiber type. Protection of the splice joint after splicing by using a suitable joint enclosure or splice tray is essential in ensuring the performance is without damage or weakening.

A: A fiber patch panel is an apparatus mounted and used to splice and manage installed optic cables in data centers and telecom networks. It is essential as it helps organize and manage the many wires neatly while simultaneously allowing simple breaking and rerouting of the fiber optic cables. Fiber patch panels with installed splicing are widely used in switching devices due to their compactness and proper network functioning, which prevail even in fiber patch panels cluttered with oil-based cables and multiplexers.

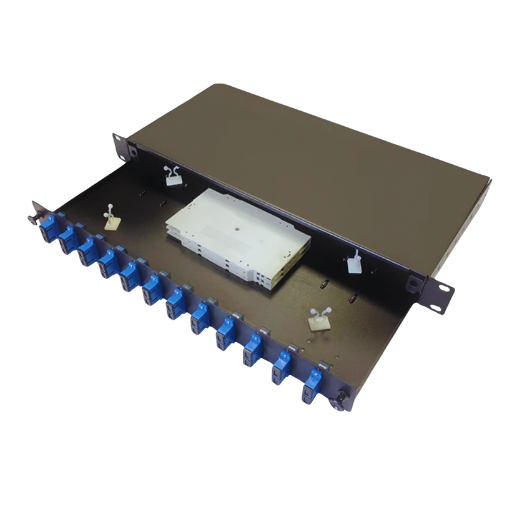

A: A 1U fiber patch panel is typically contained in 19-inch racks, and transverse occupies one rack unit horizon, measured to be 1.75 inches. A panel of a definite size usually accepts a certain maximum number of fiber connections. Most are built with the lgx patch panel standard as its core. The other type of fiber patch panel is the LGX-compatible one, which is desired with LGX (Legal Gateway Exchange) form factors and can be modular and scalable. It is also helpful for comparing fiber optic network arrangements through bundle adaptations.

A: SC (Subscriber Connector) or LC (Lucent Connector) fiber connectors remain inherent to two distinct choices depending on the objective of the network. DWDM with LC connectors is used for densely packed enclosures where size is a real estate constraint, thus best suited in data centers. These can be used as singlemode fibers with duplex connectors (‘lc duplex’). SC connectors, on the other hand, are moderately sized but are still in active use today, especially in primitive setups. While deciding between SC or LC connectors for your fiber patch panel, it is vital to keep in mind the current situation, future desires, compatibility with existing equipment, and the current infrastructure.

A: In patch panels, singlemode fiber (for example, OS2) and multimode fiber are two common types of optical fibers. The single-mode fiber has a smaller core diameter and transmits light in a single direction, making it possible to use this type of fiber for long-distance applications with low signal loss. It is usually associated with yellow cabling. Multimode features a comparatively large core diameter that supports multiple internal light paths and is suitable for covering short distances over high bandwidth applications. Most of the time, aqua, colored cables are used, known as multimode. The decision that has to be made on singlemode or multimode is dependent on how far and how much bandwidth the network has to support.

A: A fiber adapter panel is an interchangeable element of a modular fiber patch panel that retains one or more fiber optic adapters or couplers. A patch panel with three adapter panels or cassettes is a modular system that you can fill in as per your fiber connection needs. Each adapter panel has a capacity for a fixed limit on the number and type of fiber connections, for example, 12 fiber LC duplex. This type of modular design allows the user to reconfigure their patch panel design to fit any requirements that may arise in the future, for modifications to be undertaken quickly, or to incorporate upgrades shortly.

A: Pigtails in fiber optics pertain to short cable pieces with a connector at one end and an unattached fiber at the other. Sometimes, pigtails connect the fibers inside the cable to the adaptors of the patch panel. It is easier and tidier since the fiber can be spliced to a patch panel, and the other end of the pigtails can be connected to the patch panel. Pigtails can be produced for most of the common connector types, including the LC, SC, and singlemode and multimode fibers.

A: Cleaning and maintenance in a fiber patch panel are essential for the system’s good performance. Some examples are: 1. Check the panel surfaces for dust or disposable rubbish. 2. Clean the panel and adapters with compressed air. 3. Use fiber optic cleaning kits to clean fiber and adapters. 4. Deburring and cleaning the insulating material on the ends of optical fibers. 5. Install dust caps on empty connectors. 6. Do not make sharp turns or pressure the cables. 7. Write down all the connections and where the changes have occurred in the panel.

A: A 24-core fiber optic cable means a fiber optic cable having a bundle of 24 individual optic fibers. For example, in patch panel installations, A 24 core cable offers many connections with a single cable run. In times where high-density cabling is required in such facilities as data centers and large network installations, A 24 core cable can easily be broken down at a compatible patch panel to offer 12 duplex fiber optic Termination connections (a total of 24 simplex Termination connections can be adopted).