The 800G OSFP loopback module, as an O\&M tool, is providing strong support for network equipment verification and troubleshooting, playing an important role in device testing, fault diagnosis, and network optimization. Today, let’s take a closer look at the 800G OSFP loopback module.

A Loopback Module is a hardware tool used for network equipment testing. It works by looping the transmitted (Tx) signal directly back to the receiving (Rx) port, simulating actual data transmission. This allows verification of a device’s port functionality, link status, and signal integrity.

The 800G OSFP Loopback Module is a passive or active testing device designed to verify the electrical and optical performance of 800G OSFP ports without the need to connect external optical fibers or transceivers. It achieves self-testing and performance validation by looping the Tx signal directly back to the Rx port.

The 800G OSFP Loopback Module is an emerging optical module form factor that provides a cost-effective and flexible solution for testing 400Gbps/800Gbps OSFP ports, board-level system testing, and power-on verification.

Encased in a standard OSFP housing, the loopback module supports 800G transmission (8 channels @ 112G PAM4). Data sent from the host is routed through the internal circuitry of the loopback module and returned to the host’s receiving port. This enables economical OSFP port testing during R&D verification, production testing, and field testing.

The working principle of a loopback module can be divided into passive and active types.

A passive loopback (pure electrical loopback) is primarily used to test electrical interfaces, such as SerDes signal quality. In this mode, the host device (switch or tester) sends 8×106.25G PAM4 electrical signals, which are directly routed back to the receiving end via PCB traces. This type contains no optical components and is intended solely for verifying the integrity of the electrical link.

An active loopback (opto-electrical hybrid loopback) is suitable for testing the complete optical module link, including key components such as the DSP and laser. During operation, the electrical signals sent from the host are first converted into optical signals via the built-in DSP and VCSEL/EML laser. The optical signals are then reconverted into electrical signals through a PIN photodiode and returned to the host. In addition, active loopbacks support PRBS pattern testing (e.g., PRBS31), enabling bit error rate (BER) verification for a more comprehensive performance assessment.

Port Self-Test

Quickly verifies whether the OSFP port of a switch or router is functioning properly without requiring an external optical module, enabling instant checks on-site or in the lab.

Bit Error Rate (BER) Testing

Supports multiple pseudo-random bit sequence patterns (PRBS7/PRBS31), achieving BER as low as <10⁻¹⁵ with FEC enabled to ensure high link reliability.

Signal Integrity Analysis

Measures and analyzes key indicators such as PAM4 eye diagrams, jitter, and signal-to-noise ratio (SNR), providing valuable data for high-speed link tuning and quality assessment.

Compatibility Testing

Verifies whether the host device supports standards like 800GAUI-8 and CMIS 5.0, preventing incompatibility issues during deployment.

Power Consumption & Temperature Monitoring

Reads real-time power usage and temperature via the I²C interface (active models only), supporting operational status tracking and thermal management.

1. Excellent Signal Integrity with 400/800Gbps Support

The OSFP loopback module offers excellent signal integrity, enabling cost-effective and flexible 400Gbps/800Gbps OSFP port testing, board-level system testing, and power-on verification. This ensures reliable performance evaluation while reducing the need for costly optical components during testing phases.

2. Efficient Testing and Quick Fault Location

By looping signals back to the receiving end, the loopback module can quickly verify the functionality of a device’s port, helping O&M personnel efficiently pinpoint network faults and minimize downtime.

3. High Compatibility for Diverse Device Scenarios

The 800G OSFP loopback module is compatible with network equipment from major vendors and is suitable for switches, routers, servers, and other hardware, meeting the testing needs of various scenarios.

4. Hot-Pluggable Design for Ease of Use

With hot-plug capability, the module can be installed or replaced without shutting down the device, greatly improving operational efficiency.

Factory Testing of Network Equipment

In the production phase, loopback modules are used to test device ports, ensuring performance meets standards and reducing the rate of defects upon delivery.

Data Center Operations and Maintenance

During deployment and maintenance in data centers, loopback modules help O&M teams quickly verify device connectivity, ensuring stable network operation.

Fault Detection and Diagnosis

When network connection issues arise, loopback modules can quickly pinpoint the fault location, reducing troubleshooting time and improving maintenance efficiency.

R&D and Testing Environments

In the R&D stage, loopback modules are used to validate the performance and compatibility of new devices, providing valuable data to support product optimization.

Data Center Network Testing

Optical Module Verification: Insert a loopback module into a 200G QSFP56 optical module to check optical power and bit error rate (BER).

Switch Port Diagnostics: Test 400G QSFP-DD ports on switches such as Cisco Nexus 9000 or Arista 7050.

5G Telecom Equipment Debugging

Front-haul/Mid-haul Testing: Verify the link status of 25G/100G optical modules between the AAU (Antenna Unit) and DU (Distributed Unit).

Server and Storage Networks

NIC Self-Test: Use an SFP28 loopback module to test the 25G ports of Mellanox ConnectX-6 network interface cards.

As a vital tool in network testing and maintenance, loopback modules can be categorized according to testing method, interface type, application, and extended functions, providing tailored and efficient solutions for different scenarios.

Loopback modules are available in two main types: passive and active.

Passive loopback modules perform pure electrical signal looping, ideal for verifying SerDes signal quality and link integrity. They feature low cost and zero or minimal power consumption.

Active loopback modules support electrical–optical–electrical conversion, integrating DSPs, lasers, and photodiodes to enable full link testing, including bit error rate (BER), eye diagram, and jitter analysis. They are well-suited for high-speed and long-distance precision measurements.

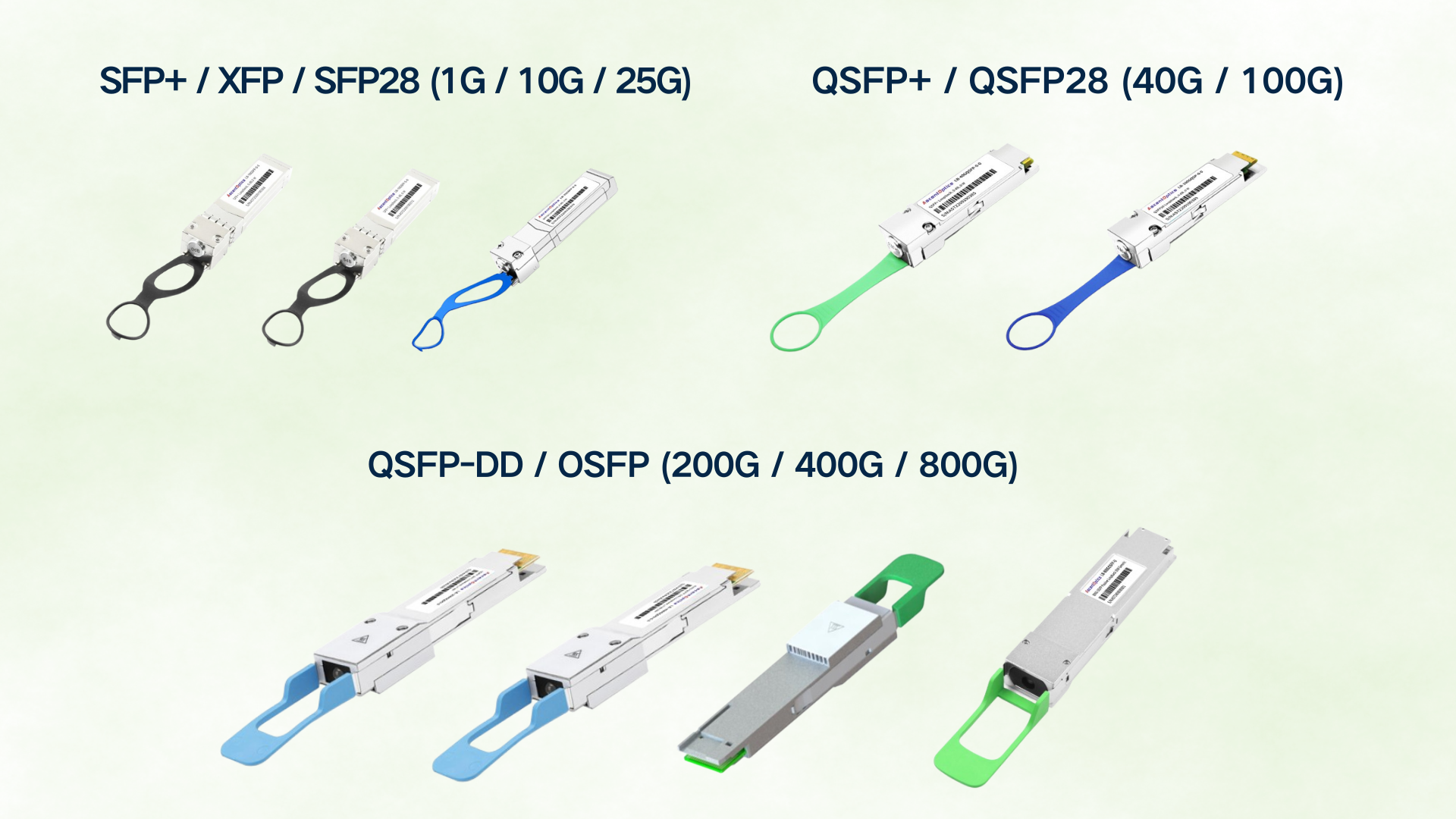

Loopback modules support a wide range of speeds and form factors, including:

SFP+ / XFP/ SFP28 (10G / 25G)

QSFP+ / QSFP28 (40G / 100G)

QSFP-DD / OSFP(200G / 400G / 800G)

This ensures compatibility from legacy gigabit networks to the latest ultra-high-speed systems.

Production Testing: Validates port performance before devices leave the factory.

Maintenance & Troubleshooting: Quickly locates faults in ports or links, reducing downtime.

R&D Testing: Verifies the performance and compatibility of new products.

Training & Labs: Used for educational demonstrations and network simulations.

Advanced loopback modules may include PRBS pattern generation and detection for BER testing, real-time power consumption and temperature monitoring via I²C, support for multiple protocol standards (e.g., CMIS, 800GAUI-8), and adjustable signal attenuation or distortion to simulate complex network conditions.

Focus on Quality

Select a high-quality loopback module to ensure stability and reliability, avoiding inaccurate test results caused by product defects.

Verify Compatibility

Choose a loopback module that matches your actual network equipment to prevent incompatibility issues.

Consider After-Sales Support

Opt for suppliers that offer comprehensive technical support and after-sales service, ensuring any issues encountered during use can be resolved promptly.

In summary, the Loopback Module is a versatile tool for network operation and maintenance as well as testing. Whether it is used for quickly locating port or link faults, performing optical module and cable acceptance tests, or verifying links during data center and 5G network deployment, it plays a vital role. Depending on testing requirements, a low-cost passive loopback module is suitable for short-distance basic testing, while an active loopback module with signal analysis capability is recommended for high-speed or long-distance precision testing to ensure comprehensive and accurate results.