When it comes to server management, there is nothing more important than installing rack-mounted servers correctly. But how do you go about doing just that? Well, one component necessary for this process is a cage nut – or several cage nuts if we’re being honest. These handy little devils provide an easy way of securely mounting equipment in a rack cabinet and making sure everything stays stable while also allowing for quick changes whenever necessary. They’re not without their downsides, though, so read on! In this guide, I’m going to cover everything from what cage nuts are made out of right down to why you should care even if your computer doesn’t use them directly (spoiler alert). So, let’s dive into some details about these useful contraptions, shall we?

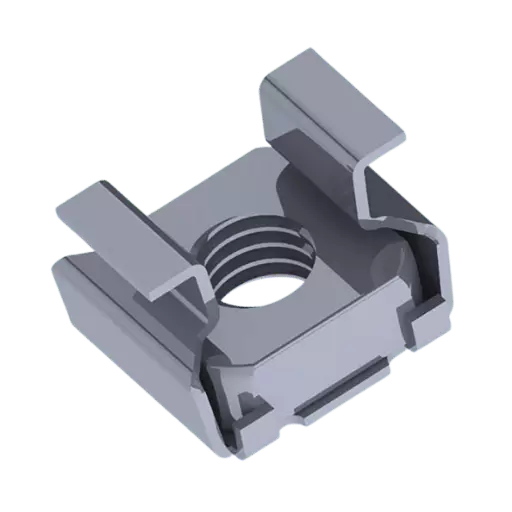

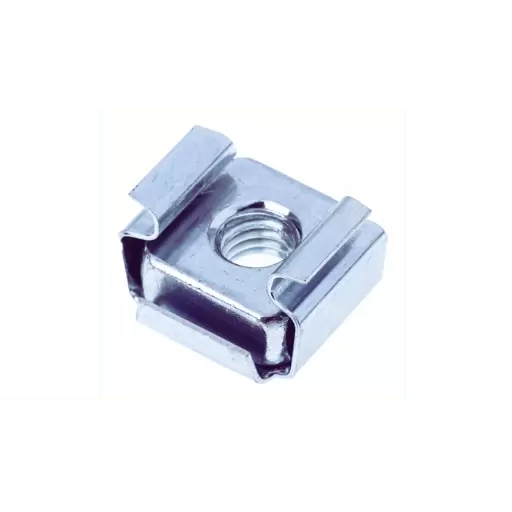

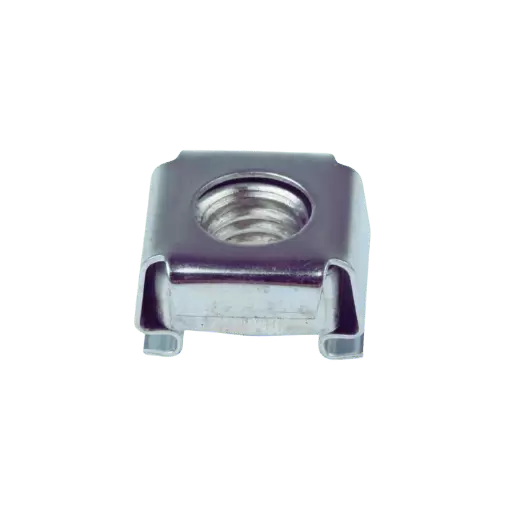

A cage nut, also referred to as a captive nut, is a square hole nut that sits inside of a spring-steel cage. This cage can be easily inserted into the square mounting holes on a server rack. The nut is floated within the cage so that it can take up minor alignment adjustments. The flexibility and versatility of these kinds of nuts make them necessary for securely mounting different types of equipment in racks while ensuring stability and ease of maintenance.

A typical rack-mount server cabinet consists of:

In server racks, cage nuts are essential for fastening equipment to the rails. They enable the mounting of components in various places, which can be moved slightly until they align correctly. This feature makes it possible to fix devices tightly so that they do not shake and get spoilt easily. Through the use of cage nuts, administrators can install, service, or reorganize devices in the rack promptly, thus enhancing operational robustness and serviceability.

Cage nuts come with many advantages as opposed to different fasteners, therefore being preferred in server racks and enclosures. First, they are versatile enough to fit into different sizes of racks and types of threads thus making sure that they work well with various equipment models. The use of cage nuts largely simplifies the process of tightening parts since they can be easily installed or repositioned without needing any special tools. Additionally, their construction from spring steel provides a strong hold that does not get weakened even under extreme pressure caused by heavy loads on mounted equipment. With zinc coating, corrosion resistance is increased, thereby ensuring long-term dependability in diverse environmental conditions where these nuts may be used. In general, cage nuts offer more flexibility, durability, and ease of maintenance than other types of fasteners.

Cage nuts stand out among other hardware due to their unique design and functions. Traditional screws and bolts as fasteners may require specific alignment or thread size for the rack or device, thus limiting their universality. However, cage nuts can be installed quickly in various configurations, which provides flexibility when mounted on stainless steel black server racks. Besides this, they also boast better load distribution that reduces the chances of damaging a rack or device when subjected to heavy weights, unlike traditional fastening methods. Most screws lack springs like those found in cages hence over time, becoming loose but still unable to achieve stability throughout like them springs do so bestowing these two features upon them alone makes all difference possible between variously fitted things up there forevermore rusting apart from one falling off after next rusting each without ever having been truly held tightest at all – even though we know what should happen if only were true factor within those circumstances concerning our ability to conceive such possibility somewhere around hereabouts now don’t you think so too? Finally, cage nuts also have an advantage over other fasteners because they are coated with zinc, which further improves their durability by preventing rusting when used in harsh settings. So, what else can I say about these lovely little creatures that hold things together? Nothing really except maybe one thing: they’re always there for us when we need them most, supporting our every move until the end of time.

When it comes to longevity and dependability of cage nuts, certain features contribute greatly towards this. One is the fact that they are made from strong materials, which makes them able to resist any form of deformations or breakages caused by heavy loads, hence enabling them to work well even under high-pressure applications without failing as easily as weaker ones would do under similar circumstances. Another feature worth mentioning here is their ability to withstand corrosion due to being coated with zinc, which offers better protection against rusting than if left uncoated, especially in environments where such things tend to occur frequently. Apart from these factors, another important aspect is how well-built cage nuts are designed together with additional components like washers – but let’s not go into too much detail about those now, shall we? All I know is that everything works fine whenever I use my favorite type, called “cage,” so I guess that speaks volumes all by itself. Don’t you think so, too?

In order to buy a cage nut and its related accessories, many well-known online shopping websites are available. Some of these include Amazon (amazon.com) and eBay (ebay.com), where you can find various types of cage nuts with customer reviews that will help guide your choice. Also, specific hardware and electronics suppliers like Newegg (newegg.com) or RackSolutions (racksolutions.com) have different kinds of cage nuts, among other mounting hardware options for sale. These platforms usually allow easy comparison between products, give detailed descriptions about them, and may offer discounts based on quantity purchased.

When deciding between purchasing either a 50-pack or 100-pack of cage nuts, there are many things one should take into account so as not to waste money. For smaller projects or single-time installations, it might be enough with just getting m6 x 16mm computer rack mount screws in packs of fifty which also happens to be cheaper than buying one hundred at once, but if it is going to be frequently used, then having more on hand would save time ordering later on, therefore, getting value for money is enhanced by acquiring one hundred pieces at once which offers lower cost per unit plus ensures availability reducing frequent reordering needs when numbers are big. So knowing the size and scope of the project is key.

There are several reputable brands and manufacturers that produce high-quality cage nuts. Some examples include APW Wyott, Eaton, and StarTech, who all have a good reputation within this industry for their strong build quality as well as accurate engineering methods used during production stages; these companies also implement strict quality control measures throughout every step, thus ensuring tight fittingness together with consistent performance under different environmental conditions such like temperature variations among others. Therefore, going for any of these brands will guarantee the durability and performance of your cage nuts during installation.

Cage nuts, which are also known as hardware cage nuts, are used for mounting equipment in a server rack. They consist of a steel square nut in a spring steel cage that clips into the square hole of a rack mount shelf for series ii rack mount solution. This fastening allows screws to be easily attached securely.

To add cage nuts you will need to align a cage nut with one of the square holes on your server rack’s vertical rails. Using pliers or a special tool designed for this purpose, pinch its sides then push it through until it snaps into place by passing all other obstacles such as wires or cables present there before repeating these steps where necessary .

Typically m6 screws are used together with their corresponding screw mates – either another m6 or its equivalent size – though there could be instances when you may have to use square insert nuts instead. These screws should fit securely into the cage nut, ensuring that you choose the correct size and type so as not to cause any damage or instability.

Washers, in this context, help distribute the load evenly, thus reducing the chances of damaging mounting holes due to excessive pressure focused at one point from the screw alone. Additionally, they play an important role by preventing the loosening up of screws over time, thereby contributing towards stability within the whole setup.

A: For a 1ru series ii rack mount, you should only use cage nuts that are made specifically for this kind of rack. See if they can be replaced by screws and find out their sizes, like 16mm computer rack mount cage nuts.

A: These are shelves that support equipment in black steel server racks. You may install them with screws or washers, stainless steel black servers, or screws and washers for rack mount servers. Line up the shelves with rack screws and cage nuts, then tighten them securely.

A: Yes, some rustproof steel black server rack screws exist. Some designs could be screws and washers of stainless steel, which are great for dependable, long-term server installations.

A: While considering vertical mounting ensure mm rack mount cage nuts hold on to rails supporting equipment firmly enough. Check that all hardware is rated according to weight ratings displayed on each device so as not cause any falling off or malfunctioning.

A: They are versatile enough to serve almost every application related to securing various devices onto the racks including shelfs meant for mounting servers among others but always check if they will fit into your specific server rack configuration.

A: Yes, you can, however, ensure new replacement parts match those found before, especially steel black server ones or screws, along with their respective washers type, lest they don’t work well together.