Data transmission has been transformed with the introduction of fiber optic cables, with their superlative speed, reliability, and efficiency. Understanding the technology behind fiber optics is essential, especially as businesses and industries work to keep up with demand for high-performance connectivity. This article aims to be a one-stop shop for everything that explains the basics of fiber optic cables, including their benefits, applications in different industries, and Hitronic® fiber optic solutions, known for their unmatched quality and innovative technology, will also be discussed. This guide prepares industry professionals and curious minds alike with everything they need to understand the workings and impact of fiber optics technology in the digital world.

Fiber optic cables are high-speed data transmission media that transport information using light pulses. They consist of very thin glass or plastic strands, each enclosed by a cladding layer that reflects light within, thereby minimizing signal loss. These cables transmit light signals over extensive distances with incredible speed and accuracy, which makes them appropriate for telecommunications, the internet, and data networks. Fiber optic cables enable high bandwidths and large electromagnetic interference, which makes these cables trustworthy and effective for contemporary communication systems.

The advance of optical fiber technology over traditional methods of communication such as copper cables has revolutionized modern computer systems. One main highlight of optical fiber communication is bandwidth. One optical fiber line is able to support a data stream of above 1 Tbps terabits per second, making it suitable for cloud computing, streaming services, and even cloud data centers.

Copper wires are slower because of their high attenuation and need more signal amplification to function, while optical fibers transmit data with low signal attenuation. Optical Fibers also dividedly transmit information more than 100 km without the need for repeaters. Fewer signal amendments reduce infrastructure spending, especially in long distance communications.

Because copper wires contain metal, they are able to cause data signal interruption but optical fibers which are lightweight can resist electromagnetic interference, allowing data signal transport in high electric noise areas.

In addition, optical fiber systems have great longevity and resistance to deterioration, which makes them appropriate for extreme environments. The world is expected to embrace optical fiber technology and its applications, owing to the demand for fast and dependable means of communication at a compound annual growth rate (CAGR) of 8.5% between 2023 and 2030. This continuing development and adoption into various fields underlines the significance of the innovation and communication capabilities of Optical Fiber Technology.

Silica glass and polymer materials make the most modern of fiber optics systems, each providing some properties that aid performance in particular areas. Glass fibers are mostly made of pure silica (SiO2), which are renowned for their low signal attenuation and superb optical clarity, ideal for transmitting data over long distances. Telecommunication networks and massive infrastructures are greatly aided by high-purity silica glass, which allows the transmission of light signals over hundreds of kilometers with minimal loss.

Fiber optic systems gain flexibility and lower costs thanks to polymers. Polymer Optical Fibers (POFs) are made of polymethyl methacrylate (PMMA) or perfluorinated polymers, which provide superior bendability, making them easier to install than glass fibers. POFs’ higher rates of signal attenuation don’t hinder their performance at short distances, making them ideal for home networks, industrial automation, and automotive systems.

Further developments in material science are focused on the performance of fiber optics. Incorporating germanium dioxide (GeO2) dopants into the silica glass fibers is one such example. It alters the refractive index profile of the glass, which significantly reduces the loss of signal. Furthermore, bandwidth capabilities have been enhanced with recent improvements in graded-index POFs, allowing data rates to exceed 10 Gbps in local area networks.

Looking into the future, the demand for high-speed internet, as well as the introduction of 5G will enable the market size for optical fiber materials to reach an impressive $15.5 billion by 2030. The expansion of the fiber optics market on a global scale can be greatly attributed to these factors. Furthermore, ensuring flexibility and optimization of diverse application combinations of plastics and glass will solidify the dependability of fiber optics technology in the fields of contemporary communications.

Thin strands of glass or plastic fibers transform electrical impulses into light beams. Each fiber transmits data in the form of light pulses, traveling at astonishing speeds. The technology ensures only minimal loss of light signal, or internal reflection, over long distances while keeping light confined within the core of the fiber.

Due to its bandwidth potential, fiber optic transmission provides remarkable efficiency and capability. Today’s modern applications, such as cloud computing or data transfers, require data to be streamed at several terabits per second. Along with streaming, these other data-intensive applications could also be performed simultaneously without any delays. Further increasing the capacity and flow of data streaming to multiple users at once comes from advanced multiplexing techniques such as DWDM, or Dense Wavelength Division Multiplexing, which permits the parallel transmission of multiple data streams across one single fiber using various light wavelengths.

Recent findings indicate that innovations in fiber optic technology have been scaled in both reach and speed. Some experimental fiber optic systems have indicated that it is possible to surpass 1 petabit per second transmission rates, proving that these systems are fully scalable for future demands. In addition, innovations in fiber materials and signal amplification technologies have made it possible to extend the effective transmission distance to thousands of miles without degradation, making fiber optics critical for international communication infrastructure.</br>

High Bandwidth Capacity

The Hitronic® fiber optic cables allow for exceptionally high volume streams of data to be transmitted. They can, for instance, handle data rates of over 400 Gbps per wavelength due to advanced multiplexing technologies. This feature makes the fiber optic cables ideal for large-scale networks and data centers.

Low Signal Attenuation

The cables also have minimal signal loss, which allows data to travel GREAT distances without additional amplification. With regards to \, Hitronic® cables, they efficiently maintain signal integrity beyond 100 kilometers, ensuring long-haul communication is reliable.

Superior Signal Quality

Hitronic® cables make use of advanced broadcasting technologies alongside high purity raw materials to make sure that signal distortion and signal dispersion is at a minimum. In turn, this means that data accuracy and clarity transmitted even in high-performance applications is greatly improved.

High Resistance to Electromagnetic Interference (EMI)

Since fiber optic cables are immune to EMI, this makes they are best suited for operation in high electrical noise environments. Data transmission in telecommunications hubs, industrial facilities, and critical locations is uninterrupted.

Enhanced Durability and Reliability

Fiber optic cables are best suited for operations in harsh environments which include extreme temperatures, physical stress, and chemical exposure. Hitronic® cables also have robust construction guaranteeing long term performance while decreasing maintenance needs.

Hitronic® Cables Increase Data Traffic Flexibility

Due to the rising need for faster data transfer, Hitronic cables offer modifications by implementing Wavelength-Division Multiplexing (WDM). This capability is critical for accommodating newer and advanced network system integrative technologies.

Operational Sustainability

In terms of power, Hitronic cables require little power to transmit and amplify signals which means, Eco-friendly operations and reduced business costs, therefore, improving energy efficiency among communication networks.

Reduced Physical Footprint

Urban areas and high-density surroundings require technologies that are easy to install and do not require a lot of space. Hitronic fiber-optic cables are lightweight and compact which makes them easy to install, therefore, making them perfect for city use.

Due to the above stated reasons, Hitronic fiber-optic cables top the list of modern data transfer cables as they deliver unmatched value unmatched value no matter the volume of work.

To send data over vast distances, fiber optic cables use light signals. In fiber optics, there are two main types of transmission: multimode, and single-mode- each has its own unique uses and advantages.

Multimode Transmission

As is evident, in multimode fiber, multiple modes ‘light rays can propagate simultaneously through the core. Multimode fiber has a core diameter of around 50 to 62.5 microns, which is relatively large in size. Although this encourages high data transmission, it can result in modal dispersion – a phenomenon where different light modes arrive at different times, resulting in a degraded signal. Multimode fiber is often utilized in short-range applications, including data centers, local area networks (LAN), and internal building connections. Its data transfer capabilities are anywhere from 10 Mbps to 100 Gbps, however, its maximum distance of transmission is usually capped at 550 meters for 10 Gbps speeds due to dispersion.

Single-Mode Transmission

Single-mode optical fibers have a core with a diameter of about 9 microns, which enables the transmission of one light mode only. This design minimizes attenuation and dispersion, enabling data signals to cover long distances without significant loss of quality. Single-mode fibers are preferable for long-distance and high-speed communication systems such as metropolitan area networks (MANs) and telecommunications networks spanning thousands of kilometers. They can support data rates over 100 Gbps, making them vital for the 5G infrastructure and international submarine cable systems. Single-mode fibers minimize signal distortion, supporting high fidelity and precision in data transmission.

Technological Improvements and Comparison

The use of multimode fibers is economically beneficial for short-span applications owing to the availability of inexpensive light sources such as LEDs and a cell termination. Single-mode fibers are now regarded as the standard for long-haul networks because of technological advances in laser module design, Wavelength division multiplexing (WDM), and VCSEL integration. These technologies enhance network capability by allowing multiple streams of varying data to be simultaneously transmitted through a single fiber, thus increasing the network’s bandwidth and overall performance.

Data Interpretation

Attenuation, a performance indicator, evaluates the reduction of signal power as light succumbs to loss while traveling along a cable. For single-mode fibers, attenuation is approximately 0.4 dB/km at 1310 nm wavelengths; in the case of multimode fibers, it is approximately 3 dB/km at 850nm; hence, single-mode fibers are very important for long-distance communications, while multimode fibers are useful in cheaper short-distance communications.

It is crucial to comprehend the differences between multimode and single-mode if they are to choose the correct optic fiber solution that meets the infrastructure requirements for today and can expand in the future in the context of International telecommunication networks.

Electromagnetic interference (EMI) poses a significant challenge to data transmission, particularly in environments with high-density electronic equipment or extensive cabling. EMI occurs when electromagnetic fields disrupt the transmission of signals, leading to degraded performance, slower speeds, and in severe cases, complete signal loss. This interference can originate from a variety of sources, including power lines, wireless devices, heavy machinery, and even solar activity.

According to current technical insights, copper-based communication systems are particularly susceptible to EMI due to their reliance on electrical signals. For example, in Ethernet networks using unshielded twisted pair (UTP) cables, significant signal degradation has been observed in environments with elevated EMI levels. Shielded twisted pair (STP) cables or fiber optic cables are preferred in these conditions, as they offer enhanced resistance to interference. Fiber optics, in particular, are immune to EMI due to their reliance on light for signal transmission rather than electricity, offering greater reliability in areas prone to electromagnetic disturbances.

Modern mitigation strategies to counteract EMI include implementing proper cable shielding, grounding systems, and maintaining adequate separation between power and communication lines. Incorporating these practices into network design plays a crucial role in preserving data integrity and ensuring seamless communication, even in high-interference environments.

Lapp’s Hitronic® fiber optic cables are designed to address the demands of high-performance data transmission in various industries. Here are some of the outstanding features and parameters of these cables:

Support Automation and Data Transmitting Industries Lapp’s Hitronic® fiber optic video cables are useful for data transmitting, and automation industries as well as with telecommunication devices to make sure that the data transferred is exact and advanced. Lapp also him Hitronic fiber optic video cables sharpen through every item, lapp also tests every him for IEC certification, while others sharpen for international standards like ISO testing need to ensure the equipment can meet Global standards.

The sheath and buffer are essential protective elements of the optical fibers within fiber optic cables, ensuring their effectiveness over a long period. In this context, the buffer acts as a primary protective cover that encases the optical fibers, protecting them from mechanical impacts and environmental stress. The sheath offers an additional structural protection to the whole cable by safeguarding it from external abrasions, moisture, and extreme temperatures. These elements cumulatively increase the optical fiber cable’s durability and reliability in harsh environments while maintaining its functionality.

Cables with halogen-free materials are a safer and more eco-friendly option than traditional cables containing halogen compounds. One of the main benefits of halogen-free cables is their lower level of fire hazard. Materials containing halogens release toxic fumes and thick smoke during burning, which is dangerous to health and escape routes in emergencies. On the other hand, halogen-free cables burn with lower smoke and toxic emissions and, therefore, improve safety in confined spaces such as office towers, transport terminals, and industrial plants.

Halogen-free cables are also preferable from an environmental standpoint due to their non-corrosive capabilities. Cables that contain halogen can emit corrosive acid gases when combusted which can cause serious damage to nearby equipment and infrastructure. For instance, a small electrical fire in a data center can be catastrophic because it can damage hardware that is forced to stockpile corrosive byproducts. In contrast, these halogen-free cables can reduce these risks and help safeguard valuable equipment and prolong the life of essential systems.

Besides, compliance with new safety requirements is increasingly marked by the use of halogen-free materials which is now widely adopted, per industrial studies. For example, in the European Union, RoHS (Restriction of Hazardous Substances) directives has emphasized halogen-free options to lessen negative environmental impacts. The use of halogen-free cables is becoming more prevalent in various industries, including telecommunications and construction, because their level of safety is superior and their ecological footprint is lower.

Absorbed ITU-T standards recommend the usage of single-mode (G.652) and bend-insensitive fibres (G.657) about their effectiveness and performance to define primary key attributes with international telecommunication bodies due to their fundamental importance in the field of Telecommunication. Considered world governing bodies such as the International Board of Electrical and Electronic Engineers, International Electrotechnical Commission (IEC 60793), and Telecommunication Industry Association (TIA-568) incorporate multiple physical, transmission characteristics as well as the casing of optical fibers lying within the cable space, thus adhering to all requirements. By using this standard, TIA guarantees that optical fibers will be operational within the harsh environment of modern network towers for communication reliability.

The certifications for the safety of optical fiber systems ensure that regulatory requirements and safe operation are met. Important ones are UL (Underwriters Laboratories), which addresses overall product safety against fire and material degradation, and CE (Conformité Européenne) marking, which ensures compliance with European directives for product safety, health and hygiene, environment, and other relevant legislation. Furthermore, entities must follow ISO 45001, a global standard focusing on managing occupational health and workplace safety. All these certifications provide a framework towards minimizing risk regarding averting danger and setting limits to the use of such systems.

Glass fiber is vital to product engineering as it improves the strength, durability, and weight of a product. Its glass fiber’s high tensile strength and low weight are useful in reinforcing components since robust and lightweight structures can be crafted. Furthermore, glass fiber has great resistance to corrosion and other environmental factors, which aids in the long-term performance and reliability of components. Such features make it crucial in construction, aerospace, and automotive industries that require reliable and efficient materials.

Cladding and coating enhance the durability, functionality, performance, and protective encasement of a material. Cladding entails encapsulating the protective layer further to enhance the corrosion, wear, and impact of the enveloped substrate. Coating is the encapsulation of a thin layer on the surface of a material to improve its thermal insulating characteristics, electrical conductivity, or even aesthetics. From the construction sector all through to the energy and manufacturing industry, these techniques are critical in prolonging the lifespan of materials while ensuring their optimal performance.

About selecting or designing materials, both the environmental and functional requirements are critical for all settings—indoor or outdoor. Each application has its precise description, which is elucidated in detail below:

Indoor Applications

Temperature Control

Visual Considerations

Wear Resistance

Maintenance of Interiors

Outdoor Applications

Weather Resistance

Corrosion Resistance

Temperature Fluctuation Tolerance

Structural Integrity Under Load

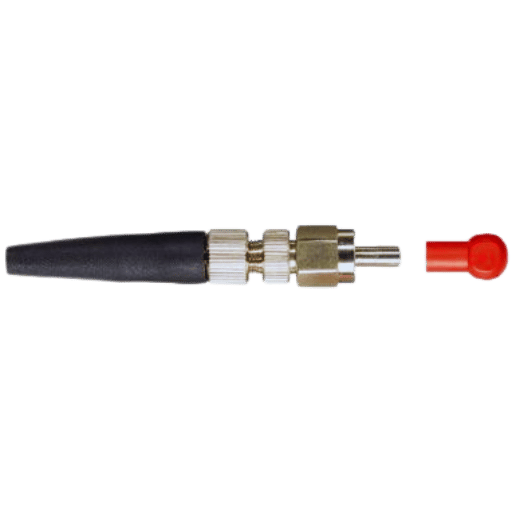

A: Fiber optic cables are made up of a core, which is surrounded by cladding, and an outer protective coating. The core is made of glass optical fibers such as those present in Hitronic® cables. These cables come in simplex, duplex, and multi-mode configurations and are intended for use as electrical data cables or fixed installations.

A: The fundamental distinction is that fiber optic cables transmit information using light rather than electricity, which gives them unrivaled speed and security when dealing with sizeable information volumes. This feature makes them well-suited for situations where data needs to be sent over long distances quickly.

A: Simplex cables only have one fiber inside for unidirectional data flow whereas duplex cables have two fibers enabling bidirectional data flow. Network systems where two-way data exchange is required regularly utilize duplex cables.

A: OM1, OM2, OM3, and OM4 are types of multi-mode fiber optic cables. They contain different core sizes, bandwidth values, and span distances. OM1 and OM2 are older standards, while OM3 and OM4 have newer, higher standards for long-distance data transfer.

A: Yes, the installation of fiber optic cables must be managed very carefully, especially with regards to bending radius and pulling tension. The cables come in flame retardant and halogen free versions for safety in certain environments. There are indoor and outdoor options. They are suggested to be installed with conduits and cable protecting accessories.

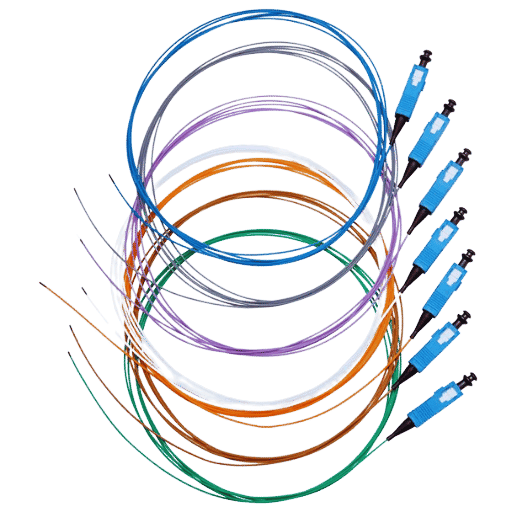

A: In fiber optic cable, connectors and pigtails have specific uses. Sections of pigtail fibers allow splicing into other fibers, while pigtails enable a secure connection to devices.

A: The glass optical fibers used in Hitronic® cables have greater functionality and relative efficacy for long haul, high speed requirements. The less costly POF is easier to deploy but is only useful for short hauls due to its lack of demanding requirements.

A: In the case of fiber optic cables, protective boundaries of the cable are created using Aramid yarns. The forces acting during installation and use are efficiently managed by Aramid yarn, enhancing cable performance over extended durations.

A: Hitronic® outdoor cables enable monitoring without area limitations, fulfilling extensive distance requirements while offering uninterrupted service. Durability against wear from moisture and shifting temperatures helps these cables deliver dependable performance.

1. “Fibre optic cable connection device, plug and plug connector for a fibre optic cable” — Lapp et al, 2005

Key Findings:

2. “Connection unit for optical waveguide cables.” — Zimmer et al, 1997

Key Findings:

Methodology:

3. “Analytical Hierarchy Process Method as a Solution to Fiber Optic Cable Supplier Quality” (Mubarok et al., 2024)

Core Insights:

Approach:

6. Glass