Searching for an appropriate 13a 125v power cord can feel daunting with so many available in the marketplace. Ensuring safety, efficiency, and durability is critical, whether powering essential household appliances, managing office equipment, or optimizing industrial setups. This article will walk you through the best power cord solutions for different applications and explain their features, benefits, and considerations for an informed decision. By the end, you will know precisely how to choose a 13a 125v power cord tailored to your needs, regardless of how intricate your setup is.

A 13a 125v power cord is an example of a device that provides electrical energy to a machine or appliance that draws 13 amps of current at 125 volts. Such devices are common in homes and businesses to supply power to medium-duty equipment like personal computers, monitors, or small home appliances. These types of power cords have well-built insulations such as plugs, which are standard in the United States and Canada. Also, they ensure safety while meeting the level of performance set by regulatory bodies for power delivery.

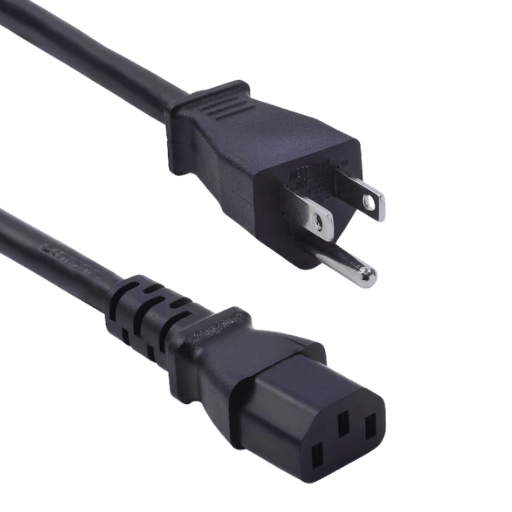

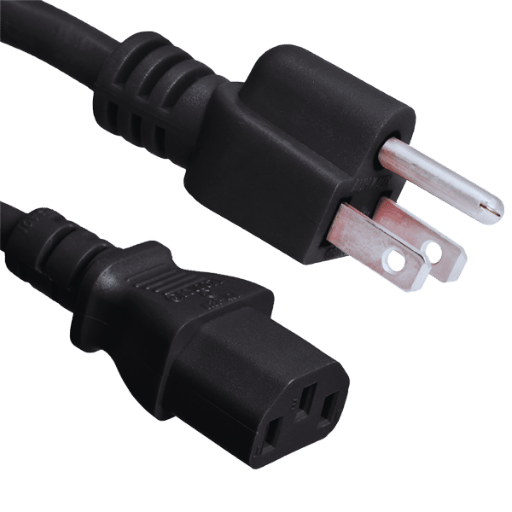

The C13 connector, as with other connectors within the IEC family, is widely used for power cords in computers and other equipment. This connector powers desktop computers, monitors, printers, and network devices. The C13 connector has three pins and is rated for a maximum current of 10 Amps and 250 volts. Due to its standardized construction, the C13 connector can be used with many different devices and is typically used with a C14 inlet, which ensures proper and reliable power connection.

The NEMA 5-15P to IEC60320 C13 power cable is one of the most convenient and dependable methods for connecting electronic devices. Below are its key features and technical specifications:

This modern power cable is suitable and reliable for providing power in various devices, making it an indispensable part of contemporary electrical configurations. Its broad compatibility alongside various devices and its strong construction improves both convenience and functionality.

The SJT cable is constructed using high-grade materials which add to its durability. The cable is protected with thick insulation which offers outstanding resistance to wear, moisture, and abrasion, ensuring longevity in different environments. Furthermore, the flexibility of the cable minimizes strain during handling and installation, reducing the chances of sustaining internal injuries over prolonged periods. Due to these factors, the SJT cable is ideal for complex tasks that require sustained performance over prolonged periods of time.

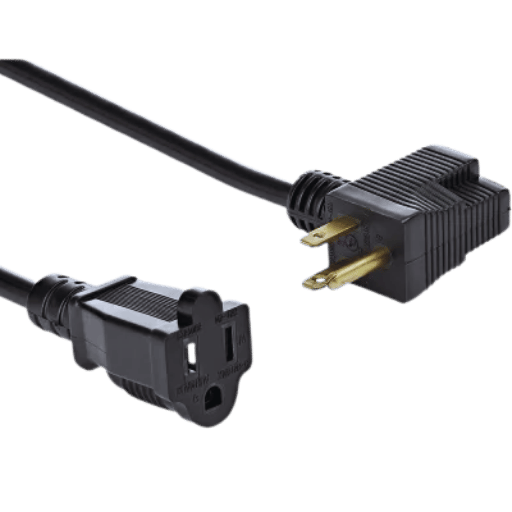

Most cords are around 6 feet long because they are generally convenient, but their applicability depends on the environment in which they are used. For example, many power outlets at desk setups are ergonometrically positioned within the 4 to 6-foot range and a 6-foot cable is long enough to connect peripherals like computers, monitors, and other devices without slack. Research on various common workspace layouts indicates that most setups in residential and office spaces are ergonometrically designed and functional within this reach range.

Alternatively, for more spacious workplaces, entertainment hubs, and industrial use, power outlets tend to be located further apart. In these cases, a longer cord measuring 9 or 12 feet is more appropriate. Cords that are too short can be excessively pulled, putting a strain on the connectors, which may lead to inefficient electrical performance and eventual damage. It is important that the distance from the device to the nearest power outlet is measured beforehand in order to appropriately select the correct length of cord to ensure safety and convenience. Furthermore, for users with limited desk space, portability, and low visual clutter, 6-foot cords usually fulfill these requirements.

Efficient Cable Management

Increased Safety

Minimized Waste and Cost Savings

Better Efficiency

Specific Requirements for Unique Use Cases

Considering these benefits, custom length orders improve functionality and safety while simultaneously achieving cost savings and environmental benefits in the long run.

The shipping and delivery of custom-length cables involves a strategic mix of efficiency, dependability, and cost control. When dealing with hazardous and fragile cables, appropriate measures of proper etiquette and strict observance of handling instruction, precision packing, and secure protection greatly reduce the risk of damages occurring during transport ”28% of compliance breaches lead to cargo damages globally, and over 11% of this is attributed to unintentional negligent wrapping of goods”.

Concrete steps and dedicated measures should also be taken to eliminate gaps in accountability, like setting production and shipping windows, assigning specific personnel to tasks, and sifting through resources to check whether they need preorders. Set running order targets for places where receipt order picking occurs. Widely known professed single tasks have pre-shipment packing quotas measured in roughly standardized global currency units. Joining forces with reliable tracking partners can reduce uncertainties whilst providing date-time stamped updates for instant delivery orders on ETA.

With over sixty percent of consumers preferring companies that use eco-friendly logistics, brand sustainability policies such as reduced carbon footprint shipping, zero-emission deliveries, and use of consolidated boxes stand to boost customer interactions. These initiatives benefit the environment by creating less waste and reducing fuel consumption and carbon footprint.

16AWG represents the standard American Wire Gauge measuring the thickness of electrical wires, with each wire gauge corresponding with a specific range of diameters. A 16 AWG wire has a diameter of approximately 1.29 millimeters and can be found in the power cords of most household and electronic appliances. The wire size permits safe current transmission of 13 amperes over short distances, which makes it ideal to be used in medium-power applications, including lighting, small kitchen utensils, and audio systems. The importance of 16 AWG lies in its balance between performance and overheating risks while meeting safety standards.

When analyzing the characteristics of the 16AWG and 18AWG wires, the most remarkable differences are present in their thickness, amperage rating, and best-suited uses. Compared to the 16AWG wire, 18AWG wire is thinner, approximately 1.02 millimeters in diameter, and smaller than 16AWG. Because of its smaller size, 18AWG wire can handle a maximum current of approximately 10 amps over short distances, less than 16AWG wire, which has a capacity of 13 amps.

For uses, 16 AWG are better for more powerful medium level items like kitchen appliances, power tools, and light-duty extension cords because they do not overheat due to higher electric load. In contrast, LED lights, USB chargers, and small electronics are powered using low-powered 18AWG wires. Because it is thinner, 18AWG wire is easier to work with in confined spaces.

Voltage drop is another important consideration, especially because it increases with distance. Due to smaller diameter, 18AWG wire has more resistance and voltage drop which impacts the overall device performance. For critical circuits wherein minimal voltage drop is significant, 16AWG can be the best choice.

Cost also plays a role, as 18AWG is typically cheaper than 16AWG because it uses less copper. However, these savings must be balanced against the appropriate voltage levels of the device’s specific application; using an oversized wire can be unsafe or inefficient.

In the end, selecting between 16 gauge and 18 gauge wires is a matter of the appropriate current load, distance, device specifications, and compliance with the safety regulations and other relevant standards.

Selecting a specific wire gauge has a direct impact on the efficiency of power delivery as well as the rate of energy transfer. For example, larger wires such as 16AWG are more beneficial because they present lower resistance, which ensures more efficient power delivery over longer distances due to higher levels of voltage retention. On the other hand, 18AWG is useful for shorter runs and for devices that do not require a lot of power. However, when misused, it can cause higher energy losses. Selecting the right wire gauge ensures that maximum performance is attained with minimal energy wastage while remaining within safe operating conditions. However, it is advisable to check relevant electrical codes and device specifications to ascertain the right wire gauge to use in a given application.

Given the class of use, hospital and medical-grade power cords are tailored to fit the strict safety and industrial reliability criteria needed for use in the healthcare environment. The patient and equipment safety is within regulatory requirements such as UL, IEC, and other medical certification standards which are the basis for these cords.

Some of the added features incorporated into the construction of hospital-grade power cords are added features for enhanced durability, such as heavy-duty construction, reinforced blade plugs, and secure connectivity. These cords are grounded for reliability and tested for resistance to physical stress, which is crucial in assuring power availability in critical settings. Equipment like monitors, imaging devices, and even infusion pumps are usually marked with a green dot indicating that the power cords are hospital-grade compliant, which suggests these devices are used in hospital environments.

For instance, a power cord intended for a hospital grade could have supporting capabilities of 13A 125V and have integrated NEMA 5-15P-HG plugs which provide sockets for IEC 60320 C13 connectors for medical devices. Like all other standards, these cables have to and are designed to provide low leakage current which reduces risk electrifically and have to and do comply with standards such as UL 60601-1.

When choosing medical and hospital-grade power cords, the specific length of the cord, range of motion, and heat tolerance should be considered for each piece of diagnostic and therapeutic machinery. Adherence to local regulations or certifications will guarantee safety and performance within the medical field. Enhanced features might also include additional antimicrobial protection in sensitive environments.

The green dot markings on power cords indicate both compliance with hospital-grade safety and performance requirements as well as the testing durability of the product in question. Such testing makes sure the power cord is suitable for the medical field by verifying the grounding reliability, resistance to strain and impact, and other factors. For the healthcare field, the visibility of the green dot on the power cords guarantees that the supplied power cords meet the set regulatory requirements, thereby boosting reliability and safety.

When assessing seller ratings and their standing, pay attention to the reviews of confirmed buyers as well as the seller’s average rating on reputable sites. Note if customers are positively commenting on the product’s accuracy, delivery, and customer service. Also, see if the seller has previous transaction records related to the field and whether they clearly state their warranty or return policies. Focus especially on the sellers who exhibit professionalism and reliability by having a history in the industry to guarantee that the purchasing process will be secured.

Expedited delivery services now impact customer satisfaction and purchasing behavior. Per research, around 88% of customers are willing to pay a premium for quicker delivery, indicating the increasing focus on speed and convenience in e-commerce. Sames-day or next-day delivery is now considered a unique selling proposition with firms providing such services retaining as much as 30% more customers than those who do not.

For companies, fast delivery not only improves the customer’s perception of the business but also allows the business to achieve better operational productivity because of streamlined supply chain management. The need to make deliveries on time is facilitated by technology like real-time stock level monitoring, sophisticated route planning, and automated warehouses. Moreover, the express delivery industry is estimated to surpass $484 billion by 2030, according to market insight data. Therefore, businesses need to formulate their logistics policies in line with changing consumer needs, defining why services need to be made faster and indicating that such policies are essential to have in place.

To find the discount that best suits them, consumers are recommended to start by checking multiple online platforms for price comparisons. A lot of online stores have specific areas that cater to deals and offers that could be changed or refreshed on a daily or weekly basis. Retailers often send newsletters or alerts, which can be very useful for gaining access to exclusive deals or discounts. Price comparison tools like Honey or Google Shopping enable users to identify the best offers quickly and effortlessly. Also, shopping during the big sales periods, including Black Friday, Cyber Monday, or end-of-season sales, most of the time ensures great discounts. Don’t forget to check the customer reviews and product ratings to make sure that the deal is genuine and that the customer actually receives a product worth something.

A: A 5-15p to C13 power cable is a type of power supply cord used in the North American market, which provides a plug for 5-15p plugs and power sockets and uses a C13 connector for inline sockets. Its importance lies in the fact that it is commonly used in conjunction with personal computers, secondary monitors, and auxiliary electronic devices, ensuring device compatibility and safe power transfer.

A: The specifications of the label indicate the power rating of the cord as 13 Amps at 125 Volts, with conductors of 16 American Wire Gauge (AWG) encapsulated in an SJT (Service Junior Thermoplastic) sheath. This combination affords the described electronic device good flexibility with the protective characteristics of the cord, which is strong.

A: Yes, there are hospital-grade power cords. Such cords are constructed to different levels of safety and reliability and are easily distinguished by green dots marking the cord. Their intended use is in the healthcare environment, and these cords are accepted for use on medical devices.

A: Always check for UL-approved power cords that are also CSA and CE-certified. These credentials guarantee safety requirements have been followed. Some cords may even feature CUL approval, which identifies these cords in both the US and Canada.

A: The most common C13 power cord length is ten feet (10ft). This offers flexibility in terms of equipment positioning. Of course, cords are also available at other lengths to cater to everyone’s specific needs.

A: The most obvious choice would have to be the gauge measurement. It is general knowledge that thicker wires can carry more load, and that explains why 14AWG is thicker. While 16AWG might be appropriate for most 13A deployments, smaller diameter cords are likely better for under 15A, which explains the heavier use of 14AWG for such applications and longer cable runs.

A: Certainly, using a 13A-125V power cord with devices having lower power requirements is safe. The rating of the power cord indicates the maximum power it can supply, which, as a result, makes it safe for devices that draw less current. Never use it with devices that draw more than 13A or 125V, though, because these values will damage the device.

A: In case of receiving a defective power cord, the individual needs to contact the seller or manufacturer immediately. Most sellers of repute guarantee undamaged parts and offer a complete return, change, or refund for items declared defective. You need to have the part number and details of the problem ready in advance. Do not use a damaged cord, as it may be dangerous.

A: While NEMA 5-15P to IEC C13 cords are commonly used and accessible with a range of devices, they are not interchangeable with every other type of cords. Like with any other device, always review the power requirements of the device and the type of inlet before attempting to use a new cord. Other devices might require varying types of plugs or different voltage ratings.